Your ASTM A672 EFW Steel Pipe manufacturer in China

Prime quality ASTM A672 CS Fusion Welded Pipe, ASTM A672 Electric Fusion Welded Pipe manufacturer in China. We carry a full inventory of ASTM A672 Pipe products in a variety of sizes to meet the project piping requirements for applications the water, petroleum, oil & gas and other industries. ASTM A671 Pipe Carbon Steel Pipe can be Structural in Nature or used in Fluid, Gas, Oil Transmission. LONGMA as one of China steel pipes manufacturerer, always supply high quality ASTM A672 Pipe materials to gobal markets.

- Grade: A55, B60, B65, B70, C60, C65, C70

- Class: 10, 11, 12, 20, 22, 50, 60, 70

- Out Diameter: 406.4-1422mm(16″-56″)

- Wall Thickness: 7.92-75mm

- Length: 3-12.5 meters

Our Certifications

Our ASTM A672 EFW Steel Pipe Product List

Longma is one of the leading ASTM A672 GR C60 C65 CL22 EFW pipes manufacturer since 2003

ASTM A672 GR C60 Steel Pipe

ASTM A672 C65 CL22 EFW Pipe

ASTM A672 C70 CL22 Pipe

ASTM A672 Pipe Materials

ASTM A672 GR B60 Pipe Specification

ASTM A672 GR B60 CL12 Pipe

ASTM A672 C65 Steel Pipe

ASTM A672 EFW Weld Steel Pipes

ASTM A672 Carbon Steel Pipe

Longma is one of the leading ASTM A672 GR C60 C65 CL22 EFW pipes manufacturer since 2003

- Longma is one of the leading ASTM A672 GR C60 C65 CL22 EFW pipes manufacturer since 2003

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

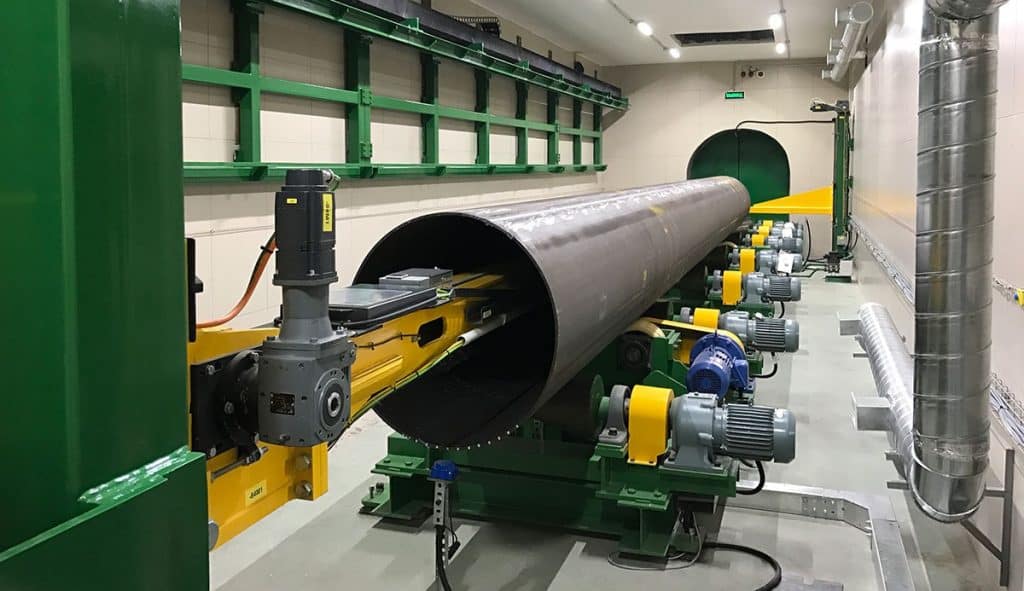

ASTM A672 EFW Steel Pipe Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

X-Ray Testing

Ultrasonic Testing

Tack Welding

Plate Ultrasonic Testing

Pipe Forming

Pipe End Bevelling

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For ASTM A672 EFW Steel Pipe

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For ASTM A672 EFW Steel Pipe

| Steel grade | C max | Si | Mn | P | S |

|---|---|---|---|---|---|

| A45 | 0.17 | / | 0.98 | 0.035 | 0.035 |

| A50 | 0.22 | / | |||

| CA55/A55 | 0.28 | / | |||

| B55 | 0.20 | 0.13~0.45 | |||

| CB60/B60 | 0.24 | ||||

| CB65/B65 | 0.28 | ||||

| CB70/C70 | 0.31 | 1.30 | |||

| C55 | 0.18 | 0.55-0.98 | |||

| CC60/C60 | 0.21 | ||||

| CC65/C65 | 0.24 | 0.79-1.30 | |||

| CC70/C70 | 0.27 |

| Steel Grade | Yield point (N/mm2) max | Tensile Stregth (N/mm2)max | Elongation (%) |

|---|---|---|---|

| A45 | 165 | 310~450 | 30 |

| A50 | 185 | 345~485 | 28 |

| A50 | 185 | 345~485 | 28 |

| CA55/A55 | 205 | 380~515 | 27 |

| B55 | 205 | 380~515 | 27 |

| CB60/B60 | 220 | 415~550 | 25 |

| CB65/B65 | 240 | 450~585 | 23 |

| CB70/B70 | 260 | 485~620 | 21 |

| C55 | 205 | 380~515 | 27 |

| CC60/C60 | 220 | 415~550 | 25 |

| CC65/C65 | 240 | 450~585 | 23 |

| CC70/C70 | 260 | 485~620 | 21 |

| Class | Heat Treatment on Pipe | Radiography, see Section | Pressure Test, see: |

|---|---|---|---|

| A672 Pipe Class 10 | none | none | none |

| A672 Pipe Class 11 | none | 9 | none |

| A672 Pipe Class 12 | none | 9 | 8.3 |

| A672 Pipe Class 13 | none | none | 8.3 |

| A672 Pipe Class 20 | stress relieved, see 5.3.1 | none | none |

| A672 Pipe Class 21 | stress relieved, see 5.3.1 | 9 | none |

| A672 Pipe Class 22 | stress relieved, see 5.3.1 | 9 | 8.3 |

| A672 Pipe Class 23 | stress relieved, see 5.3.1 | none | 8.3 |

| A672 Pipe Class 30 | normalized, see 5.3.2 | none | none |

| A672 Pipe Class 31 | normalized, see 5.3.2 | 9 | none |

| A672 Pipe Class 32 | normalized, see 5.3.2 | 9 | 8.3 |

| A672 Pipe Class 33 | normalized, see 5.3.2 | none | 8.3 |

| A672 Pipe Class 40 | normalized and tempered, see 5.3.3 | none | none |

| A672 Pipe Class 41 | normalized and tempered, see 5.3.3 | 9 | none |

| A672 Pipe Class 42 | normalized and tempered, see 5.3.3 | 9 | 8.3 |

| A672 Pipe Class 43 | normalized and tempered, see 5.3.3 | none | 8.3 |

| A672 Pipe Class 50 | normalized and tempered, see 5.3.3 | none | none |

| A672 Pipe Class 51 | quenched and tempered, see 5.3.4 | 9 | none |

| A672 Pipe Class 52 | quenched and tempered, see 5.3.4 | 9 | 8.3 |

| A672 Pipe Class 53 | quenched and tempered, see 5.3.4 | none | 8.3 |

| Pipe Grade | Type of Steel | ASTM Specification | Elongation (%) |

|---|---|---|---|

| No | Grade | ||

| ASTM A672 Grade A45 Pipe | plain carbon | A285 / A285M | A |

| ASTM A672 Grade A50 Pipe | plain carbon | A285 / A285M | B |

| ASTM A672 Grade A55 Pipe | plain carbon | A285 / A285M | C |

| ASTM A672 Grade B55 Pipe | plain carbon, killed | A515 / A515M | 55 |

| ASTM A672 Grade B60 Pipe | plain carbon, killed | A515 / A515M | 60 |

| ASTM A672 Grade B65 Pipe | plain carbon, killed | A515 / A515M | 65 |

| ASTM A672 Grade B70 Pipe | plain carbon, killed | A515 / A515M | 70 |

| ASTM A672 Grade C55 Pipe | plain carbon, killed, fine grain | A516 / A516M | 55 |

| ASTM A672 Grade C60 Pipe | plain carbon, killed, fine grain | A516 / A516M | 60 |

| ASTM A672 Grade C65 Pipe | plain carbon, killed, fine grain | A516 / A516M | 65 |

| ASTM A672 Grade C70 Pipe | plain carbon, killed, fine grain | A516 / A516M | 70 |

| ASTM A672 Grade D70 Pipe | manganese-silicon-normalized | A537 / A537M | 1 |

| ASTM A672 Grade D80 Pipe | manganese-silicon-Q&T | A537 / A537M | 2 |

| ASTM A672 Grade E55 Pipe | plain carbon | A442 / A442M | 55 |

| ASTM A672 Grade E60 Pipe | plain carbon | A442 / A442M | 60 |

| ASTM A672 Grade H75 Pipe | manganese-molybdenum-normalized | A302 / A302M | A |

| ASTM A672 Grade H80 Pipe | manganese-molybdenum-normalized | A302 / A302M | B, C or D |

| ASTM A672 Grade J80 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-1 |

| ASTM A672 Grade J90 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-2 |

| ASTM A672 Grade J100 Pipe | manganese-molybdenum-Q&T | A533 / A533M | CI-3 |

| ASTM A672 Grade K75 Pipe | chromium-manganese-silicon | A202 / A202M | A |

| ASTM A672 Grade K85 Pipe | chromium-manganese-silicon | A202 / A202M | B |

| ASTM A672 Grade L65 Pipe | molybdenum | A204 / A204M | A |

| ASTM A672 Grade L70 Pipe | molybdenum | A204 / A204M | B |

| ASTM A672 Grade L75 Pipe | molybdenum | A204 / A204M | C |

| ASTM A672 Grade N75 Pipe | manganese-silicon | A299 / A299M | .. |

It is mainly used for oil and gas transportation pipelines.

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. 1.What is ASTM A672?

ASTM A672 Pipe is Standard Specification for Electric-Fusion-Welded Steel Pipe for High-Pressure Service at Moderate Temperatures. ASTM A672 LSAW pipelines use a hot rolling process that may be standardized, quenched, disinfected, and is a thermostat and other heat treatment methods compatible.

2. What is the difference between ASTM A671 and ASTM A672?

A671 and A672 are EFW (Electric-Fusion Welded) Carbon Steel Pipes used for atmospheric and lower temperatures applications (A671) and high-pressure service at moderate temperatures (A672). As mentioned above, A671 is used for atmospheric and lower temperature application and A672 is used for high-pressure service applications at moderate temperature. However, if we compare the details e.g. A672 Gr.C60 & A671 Gr. CC60; the raw material plate used is same for both pipes & final mechanical properties are same. Heat treatment is same. The only difference between the 2 grades is only in the testing requirements. A672 requires weld sample drawn from a 500ft length of pipe and allows you to double the samples in case, original sample fails. A671 requires weld sample drawn from a 200ft length of pipe with no provision for a rejected weld.

3. What is ASTM A672 grade C65 Class 22?

The ASTM A672 Gr. c65 Cl22 has 0.98% manganese in the composition with carbon, phosphorus and sulfur. The minimum yield strength of the material is at 240MPa and the minimum tensile strength ranges from 450MPa to 585MPa. The conventional welding methods can be applied on the ASTM A672 Grade C65-class 22.The ASTM A671 Grade CC65 Class 22 EFW Pipes can be surface treated with paint, coating, FBE, galvanization, varnished, epoxy coatings, etc. They are designed with an outer diameter of 12-64 inches. The A671 CC65 Grade CL22 Low Temp Pipe is used in low-temperature.

4. What is the wall thickness of A672 pipe?

The specification nominally covers pipe 16 inches (400 mm) in outside diameter or larger and of ¼ inch (6 mm) wall thickness or greater. Pipe having other dimensions may be furnished provided it complies with all other requirements of this specification.

5. What are the properties of ASTM A672?

The specification nominally covers pipe 16 inches (400 mm) in outside diameter or larger and of ¼ inch (6 mm) wall thickness or greater. Pipe having other dimensions may be furnished provided it complies with all other requirements of this specification.

6. What is A672 B65 material?

ASTM A672 B65 Pipe is a larger diameter pipe ranging from 12 inches to 64 inches in diameter because the pipes are made through electric fusion welding of pressure vessel grade plates. The material has carbon, manganese, phosphorus, silicon and sulfur in the composition.

Featured Case For ASTM A672 EFW Steel Pipe

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.