A good large-caliber steel pipe should also be smooth, at least without a stinging feeling when the hand is touched.

It is suggested that the majority of consumers should forget to touch these products with their hands when buying this kind of steel pipe.

A good steel pipe generally feels very smooth.

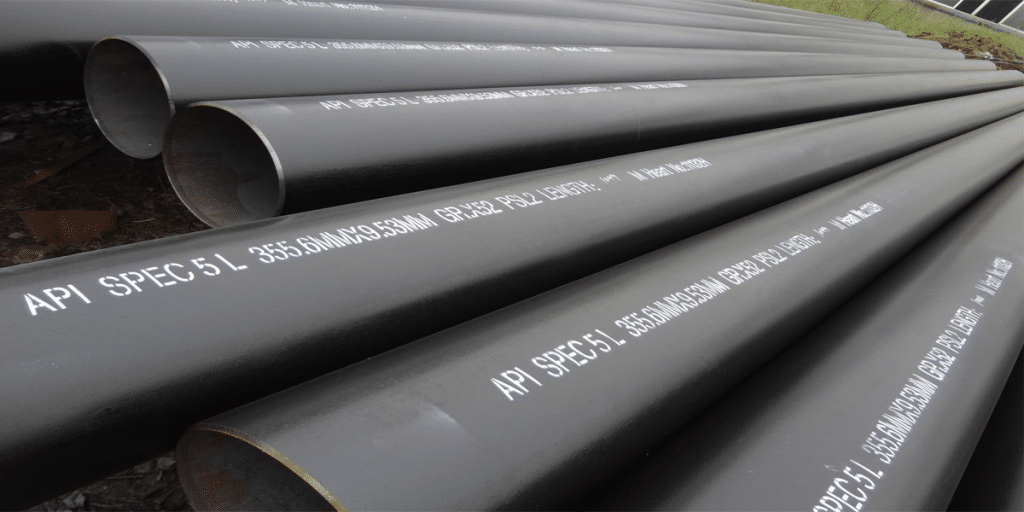

In the market, the sales of large-diameter steel pipes have been soaring, because these steel pipes have a very wide range of applications.

Whether in construction or in oil exploration, we can always see them.

Since these steel pipes have so many uses, friends should be careful when choosing and know what kind of steel pipes are excellent.

Of course, a good steel pipe will have a very good color, and a good color indicates that the manufacturer’s workmanship during production is yes.

If you encounter some steel pipes without color, it means that this product is not available.

When choosing and buying, friends should pay attention to observe the color of those steel pipes.

What should be done at the end of cooling of large diameter steel pipe?

The main results are as follows:

(1) when the cooling ends, that is, when the temperature of the surface layer and the core are all the same, the elastic deformation of the surface layer and the core also disappears and returns to the original state.

Although the instantaneous thermal stress is produced in the cooling process, the residual thermal stress is equal to zero after the cooling is terminated.

(2) of course, this is a relatively special case.

Due to the large thermal stress at the beginning of the rapid cooling process, the steel is still at a higher temperature and has good plasticity, and the thermal stress will exceed the yield strength of the large diameter steel pipe, resulting in plastic deformation of the surface layer under tension and compression at the center, thus relaxing the thermal stress.

(3) when the cooling continues, the cooling rate of the surface layer slows down, while that of the center increases, the temperature difference between the surface layer and the core decreases gradually after a larger value, and the thermal stress acting on the surface and core decreases accordingly.

(4) however, due to the above pre-generated plastic deformation, it plays a role in reducing the large thermal stress, and when there is still an obvious temperature difference, the thermal stress is close to zero.

At this time, the heart is not yet cold, and it will continue to contract when it is cooled, thus reversing the thermal stress and forming the thermal stress of the surface under pressure and the heart under tension.

(5) after cold penetration, there will be a large residual compressive stress in the surface layer and a residual tensile stress in the center.

When the molten steel is poured into the mold, due to the heat absorption of the mold, the temperature of the molten steel gradually decreases and changes from liquid to solid between the liquidus and the nursery phase line, this process is called solidification process, and this transition period is called solidification period.

(6) shrinkage, porosity, hot cracking, segregation, all kinds of pores and inclusions in large diameter steel pipes are produced in the solidification period.

Therefore, it is of great significance to understand and study the solidification law and control it for obtaining excellent and dense castings.

2. Analysis on the geometric characteristics of large diameter steel pipe section.

The main results are as follows: (1) the joint connection is suitable for direct welding, but not through the nodal plate or other connectors, which saves both labor and materials.

(2) concrete can also be poured into the pipe to form composite members when necessary.

(3) the geometric characteristic of the pipe section is good, the pipe wall is generally thin, the section material is distributed around the centroid, the rotation radius of the section is larger, and it has strong torsional stiffness; as a member under compression, compression and biaxial bending, its bearing capacity is higher, and the flatness and section size accuracy of cold-formed pipe is better than that of hot-rolled open section.

(4) the appearance is relatively beautiful, especially the pipe truss composed of steel pipe members has no extra joint connection and has a strong sense of modernity.

(5) in terms of anti-hydrodynamic characteristics, the cross section of the circular tube is better, and the effect of wind and water flow is greatly reduced.

The rectangular tube section is similar to other open sections in this respect.

(6) the large diameter steel pipe is a closed cross-section; when the average thickness and cross-sectional area are the same, the exposed surface area is about 50%-60% of the open cross-section, which is beneficial to corrosion and can save coating materials.

Non-destructive testing of the weld inside the large diameter steel pipe: because the pipe belongs to the type steel pipe in the water supply project, and the steel pipe with extraordinary thickness t=30mm is used as a pipe bridge, it not only has to bear the internal water pressure, but also bears the bending moment formed by the self-weight of the steel pipe and the water body, so the quality of welding is required to be high.

For the t=30mm thick steel pipe used in the large diameter steel pipe bridge, the longitudinal seam and circumferential seam belong to the first class weld, which requires X-ray inspection and acoustic inspection, while for the buried steel pipe with thickness t=24mm, the longitudinal seam belongs to the first class welding, 20% X-ray inspection and 50% special wave inspection.

If you want to buy good steel pipes, you should not only observe their color, but also feel their touch.

Only those steel tubes with uniform color and smooth surface can be called excellent products.

If friends do not want to be fooled by losses, when they choose to buy, they should pay attention to grasp the problems in these two aspects.