API 5L Standards and Characteristics

What is API 5L?

API 5L is a standard developed by the American Petroleum Institute (API) that is primarily focused on seamless and welded steel pipes used in oil and gas pipelines and related systems. It is designed to ensure the mechanical and chemical performance of pipes under harsh conditions such as high pressure, extreme temperatures, and corrosive environments.

Key Characteristics of API 5L

Tensile and Yield Strength: The standard sets stringent limits on tensile and yield strength to ensure the pipe’s safety in high-pressure transportation systems.

Ductility and Toughness: Materials must meet specific ductility and toughness requirements to prevent brittle fractures, particularly in low-temperature or high-impact conditions.

Corrosion Resistance: API 5L includes requirements for resistance to hydrogen sulfide (H₂S) and carbon dioxide (CO₂) corrosion, making it suitable for transporting sour gas and other corrosive substances.

Comparison with Other API 5L Grades (e.g., X52, X65) Standards

The main difference between API 5L and API 5L lies in their intended applications and performance requirements:

API 5L is tailored for extreme conditions (high pressure, corrosive environments, harsh temperatures) and offers superior strength, toughness, and corrosion resistance.

API 5L grades (e.g., X52, X65) are more versatile and cost-effective for standard pipeline applications, particularly over long distances.

Performance and Applications of API 5L Pipe Grades

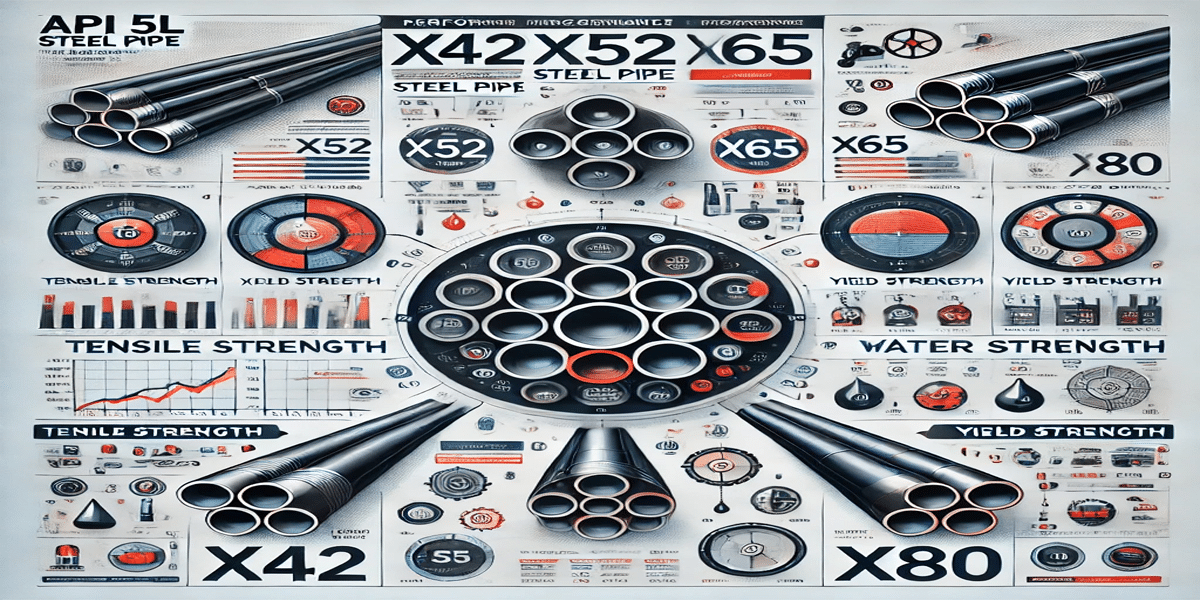

1. API 5L Grade X42

Performance:

Tensile Strength: 60–80 ksi (414–552 MPa)

Yield Strength: 42 ksi (290 MPa)

Features: Basic strength and pressure handling capabilities. Suitable for standard pipeline transportation systems.

Applications:

Used in onshore oil and gas pipelines for lower pressure systems.

Suitable for water pipelines and general industrial applications.

2. API 5L Grade X52

Performance:

Tensile Strength: 70–90 ksi (483–620 MPa)

Yield Strength: 52 ksi (358 MPa)

Features: Moderate strength with increased resistance to pressure and stress, making it suitable for more demanding pipeline applications.

Applications:

Common in onshore pipelines, particularly for gas and crude oil transportation.

Used in water treatment plants and chemical industries.

3. API 5L Grade X65

Performance:

Tensile Strength: 85–100 ksi (586–690 MPa)

Yield Strength: 65 ksi (448 MPa)

Features: Higher strength, designed for higher pressure and larger diameter pipelines.

Applications:

Offshore pipelines and deepwater oil and gas transport.

Used for high-pressure gas lines and pipeline transportation in harsh conditions.

4. API 5L Grade X70

Performance:

Tensile Strength: 95–105 ksi (655–724 MPa)

Yield Strength: 70 ksi (483 MPa)

Features: Enhanced mechanical properties for even higher pressure handling, including resistance to cracking and fatigue.

Applications:

Deepwater pipeline projects and high-pressure, high-temperature applications.

Used in onshore and offshore gas transmission pipelines in regions with extreme environmental conditions.

5. API 5L Grade X80

Performance:

Tensile Strength: 100–110 ksi (689–758 MPa)

Yield Strength: 80 ksi (552 MPa)

Features: Offers the highest strength of API 5L grades, ideal for extremely high-pressure pipelines and challenging environmental conditions.

Applications:

High-pressure gas pipelines.

Used in subsea pipelines, gas transmission, and crude oil transport in remote or difficult environments.

Higher Grades (X65, X70, X80): Designed for higher pressure, extreme conditions, and long-distance transportation. These are typically used in offshore, deepwater, and high-pressure systems.

Lower Grades (X42, X52): Better suited for onshore pipelines, lower pressure environments, and general-purpose transportation.

API 5L PSL1 & PSL2 Specification Levels

1. NACE MR 0175/ISO 15156

Context: NACE MR 0175 and ISO 15156 are standards for ensuring materials resist sulfide stress cracking (SSC) in sour environments containing hydrogen sulfide (H₂S).

Requirements:

PSL1: Typically, there are no mandatory requirements to meet NACE standards; it suits general applications.

PSL2: Certain grades must comply with NACE MR 0175/ISO 15156, making them suitable for sour service environments where enhanced corrosion resistance is critical.

Application: Sour gas fields, deep wells, and corrosive oil and gas transportation.

2. Onshore and Offshore

Onshore Pipelines:

Commonly use PSL1 grades for transporting water, oil, or natural gas in less demanding environments.

Lower performance demands compared to offshore applications.

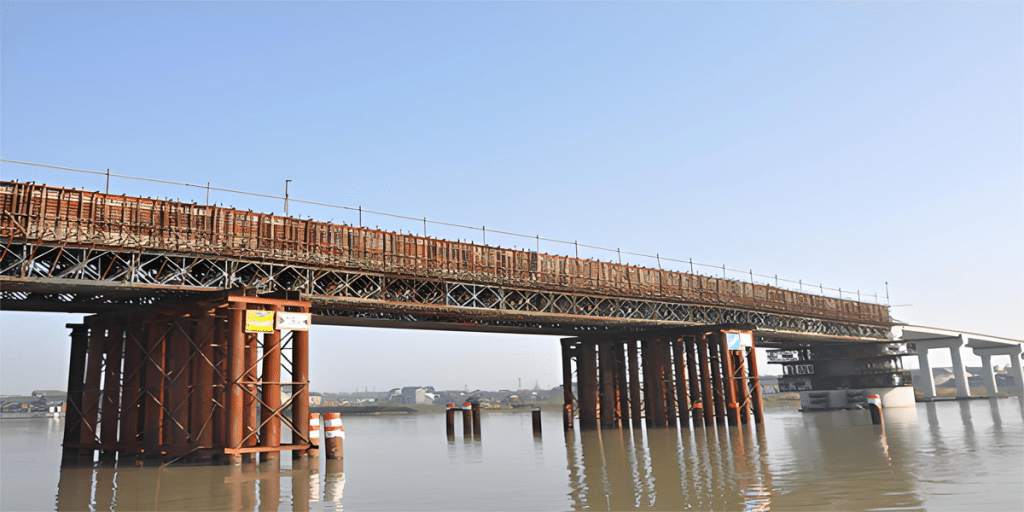

Offshore Pipelines:

PSL2 grades are preferred due to exposure to harsh environments, including high pressure, high salinity, and low temperatures.

Offshore projects often require additional properties such as advanced mechanical strength and anti-corrosion coatings.

3. Sour Service

Definition: Sour service refers to environments with H₂S, which accelerates material corrosion and induces sulfide stress cracking.

Standard Differences:

PSL1: Suitable for non-sour or standard service conditions.

PSL2: Includes strict testing and enhanced mechanical properties to withstand sour environments.

Recommended Grades: High-strength grades like X60 or X65 are frequently used in sour service applications.

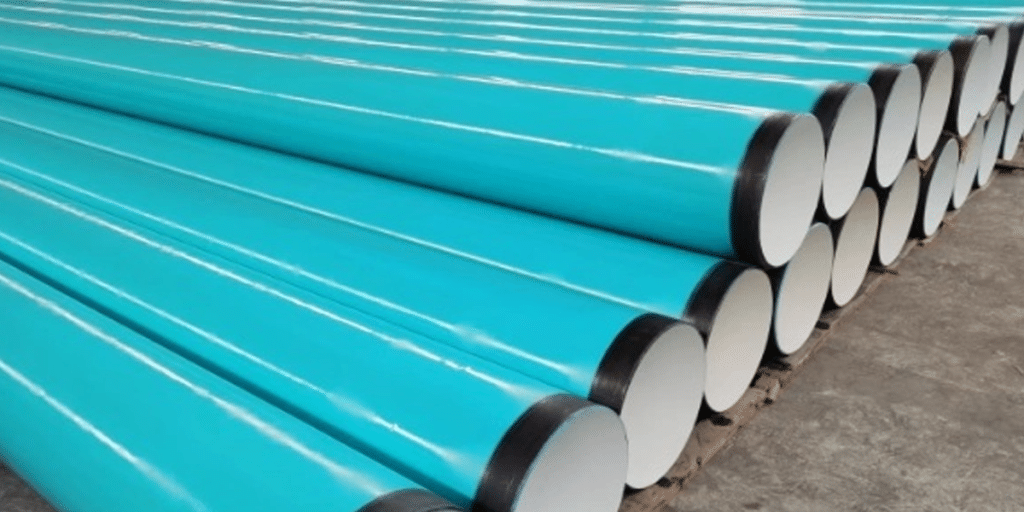

4. Corrosion-Resistant Coatings: FBE and 3LPE

FBE (Fusion Bonded Epoxy):

A single-layer epoxy coating designed for high-temperature and anti-corrosion applications.

Applications: Widely used for long-distance onshore pipelines transporting oil and gas.

3LPE (Three-Layer Polyethylene):

Combines an epoxy primer, adhesive layer, and polyethylene outer layer for superior corrosion resistance and mechanical durability.

Standards: Conforms to DIN 30670 to ensure coating consistency and performance.

Applications: Frequently applied in offshore pipelines and corrosive environments.

Usage:

PSL1: More commonly used with FBE coatings for basic onshore applications.

PSL2: Often paired with 3LPE coatings to meet offshore and high-corrosion environment requirements.

Advantages and Market Demand of Carbon Steel API Pipes

Advantages of Carbon Steel API Pipes

1. High Strength and Durability

Carbon steel API pipes offer excellent mechanical properties, capable of withstanding high pressure, high temperature, and complex environmental conditions.

High Strength: High-grade pipes like API 5L X65 and X80 have superior tensile and yield strength.

Corrosion Resistance: Enhanced through coatings, linings, or PSL 2-grade pipes for handling sour or corrosive fluids.

2. Cost-Effectiveness

Carbon steel pipes are more affordable compared to alloy or stainless steel pipes while meeting most transportation needs.

Low Manufacturing Cost: Easy production and abundant raw materials make them economical.

Optimized Transportation Cost: Thinner walls with high-grade steel (e.g., X70, X80) reduce overall weight and costs for long-distance pipelines.

3. Versatility

Carbon steel API pipes adapt to various environments and engineering needs:

Flexible Sizes: Available in a wide range of diameters.

Suitable for Harsh Environments: Heat-treated carbon steel pipes perform well in extreme conditions, such as high salinity, cold climates, or high-temperature zones.

4. Standardization and Quality Assurance

API standards ensure reliability and consistency in pipe performance:

API 5L: For oil, gas, and water transportation pipelines.

API 5CT: Specialized for high-pressure casing and tubing applications in drilling.

Market Demand for Carbon Steel API Pipes

1. Growing Global Energy Demand

The increasing exploration and transportation of oil and natural gas drive the demand for carbon steel API pipes.

Long-Distance Pipelines: Major projects in North America and the Asia-Pacific regions.

Shale Gas and Offshore Development: Higher demand for advanced API-grade pipes in challenging environments.

2. Industrial Development and Infrastructure Upgrades

Emerging Economies: Rapid industrialization in Asia and Africa requires extensive pipeline networks.

Pipeline Modernization: Upgrading older pipeline systems, particularly in North America and Europe.

3. Environmental and Safety Regulations

Stricter environmental standards and focus on transportation efficiency are shaping market trends:

High-Performance Pipelines: PSL 2-grade products are gaining popularity for their superior quality and adaptability.

Corrosion-Resistant Solutions: Pipes with external anti-corrosion coatings for handling acidic or saline fluids.

4. Renewable Energy Support: While renewable energy is on the rise, carbon steel pipes are finding new opportunities in hydrogen transportation and carbon capture, utilization, and storage (CCUS).

How to Choose the Right API 5L Pipeline?

Choosing the appropriate API 5L pipeline requires careful consideration of project requirements, transported medium, environmental conditions, and budget. Below are the key factors to guide your selection:

1. Select the Pipe Grade Based on Project Requirements

API 5L pipes are classified into two product levels: PSL 1 and PSL 2:

PSL 1 (Pipeline Specification Level 1)

Basic grade, suitable for general pipeline transportation.

Commonly used for projects with lower pressure and simpler environments.

PSL 2 (Pipeline Specification Level 2)

Higher-grade pipes with stricter mechanical properties, chemical composition, and toughness requirements.

Ideal for complex environments such as high pressure, corrosive conditions, or low temperatures.

2. Choose Pipe Material and Grade Based on the Transported Medium

1) For Gases

Recommended Grades: X42 to X65

Features: Suitable for transporting natural gas, shale gas, or other high-pressure gases.

2) For Liquids (e.g., Oil or Water)

Recommended Grades: X42 to X80

Features: Select appropriate wall thickness and material to handle the fluid pressure.

3) For Corrosive Media (e.g., Acidic Gas or Saltwater)

Recommended Grades: PSL 2 + Anti-Corrosion Coating

Features: Pipes with special treatments like internal linings or external corrosion-resistant coatings.

3. Choose Pipe Size and Wall Thickness Based on Transportation Conditions

Pipe Diameter: Determined by the flow rate and velocity of the transported medium. Larger diameters allow higher transport capacities.

Wall Thickness: Should be chosen considering pressure ratings and safety factors. Common standards include SCH 40, SCH 80, etc.

4. Select Pipe Performance Based on Environmental Conditions

1) High-Temperature Environments

Choose materials with higher yield strength, such as X65 or X80.

Use welding materials and heat treatment processes suitable for high temperatures.

2) Low-Temperature Environments: PSL 2 grades with higher impact toughness are essential to avoid brittle failure.

3) Corrosive Environments: Use coated pipes, corrosion-resistant linings, or alloy-reinforced carbon steel materials.

5. Ensure Reliability Through Manufacturers and Certifications

Ensure the supplier complies with API 5L certification standards.

Verify the manufacturing records, including chemical composition, mechanical properties, and non-destructive testing reports.

Recommended Testing Methods: Ultrasonic Testing (UT), Magnetic Particle Testing (MT), and Radiographic Testing (RT) for weld seams.

6. API 5L Recommended Application Scenarios

1. High-Pressure Environments

Application: Oil and gas exploration, especially in high-pressure extraction operations.

Reason: API 5L pipes are designed to withstand extreme pressure conditions without compromising structural integrity.

2. Deepwater and Offshore Projects

Application: Subsea pipelines, offshore oil rigs, and underwater transportation systems.

Reason: The durability and strength of API 5L pipes make them suitable for challenging marine environments with fluctuating pressure and corrosion risks.

3. Extreme Temperature Conditions

Application: Operations in arctic regions or high-temperature zones.

Reason: High toughness and thermal resistance enable API 5L pipes to perform reliably in both freezing and high-heat environments.

4. Corrosive Environments

Application: Pipelines exposed to sour gas, acidic fluids, or saline water.

Reason: The materials used in API 5L pipes, combined with protective coatings, provide excellent resistance to corrosion.

Choosing the right API 5L pipeline and supplier is crucial for ensuring the success and efficiency of your project. With the increasing demand for energy and the expansion of global infrastructure, the market for API 5L pipelines is expected to grow significantly, driven by the need for durable and efficient transportation solutions. By understanding project requirements, assessing pipeline grades, and selecting a reliable supplier, you can achieve optimal performance, cost-effectiveness, and long-term reliability.

At Hebei Longma Steel Pipe Manufacturing Co., Limited, we specialize in providing top-quality API-certified pipelines and professional support tailored to your needs. Whether it’s material selection, technical guidance, or timely delivery, we are committed to delivering excellence at every step.If you found this article helpful, please like, share, and follow us for more expert insights on pipeline solutions and engineering advancements. Your support helps us continue to serve you better!