- 1. ERW Steel Pipe Definition and Manufacturing Process of ERW Steel Pipe

- 2. Choosing the Right ERW Steel Pipe Supplier & Manufacturer

- 3. Applications of ERW Steel Pipes

- 4. Quality Control and Standards of ERW Steel Pipes

- 5. Market Trends and Future Outlook of ERW Steel Pipes

- 6. How to Choose the Right ERW Steel Pipe Supplier?

ERW Steel Pipe Manufacturing is the process of producing electric resistance welded (ERW) steel pipes, widely used in industries like oil and gas, construction, and infrastructure. This method involves welding steel coils using electrical heat to create durable and cost-effective ERW Carbon Steel Pipe. The success of ERW Steel Pipe Manufacturing depends on precise control of production, with ERW Pipe Suppliers and ERW Steel Pipe Suppliers providing crucial raw materials and technology. As demand grows, ERW Carbon Steel Pipe Manufacturers are facing increasing competition, driving innovation and shaping the future of the market. This guide will explore the key processes involved in ERW steel pipe production, how to select reliable suppliers, and the current market trends influencing the ERW steel pipe industry!

ERW Steel Pipe Definition and Manufacturing Process of ERW Steel Pipe

ERW Steel Pipe (Electric Resistance Welded Steel Pipe) is a type of steel pipe manufactured using the electric resistance welding process. It is widely used in industries such as oil and gas transportation, construction, and infrastructure. During the manufacturing process, a steel strip is heated by electrical current and welded together at the edges under pressure, forming a pipe. ERW steel pipes are known for their cost-effectiveness and are a vital component in various applications.

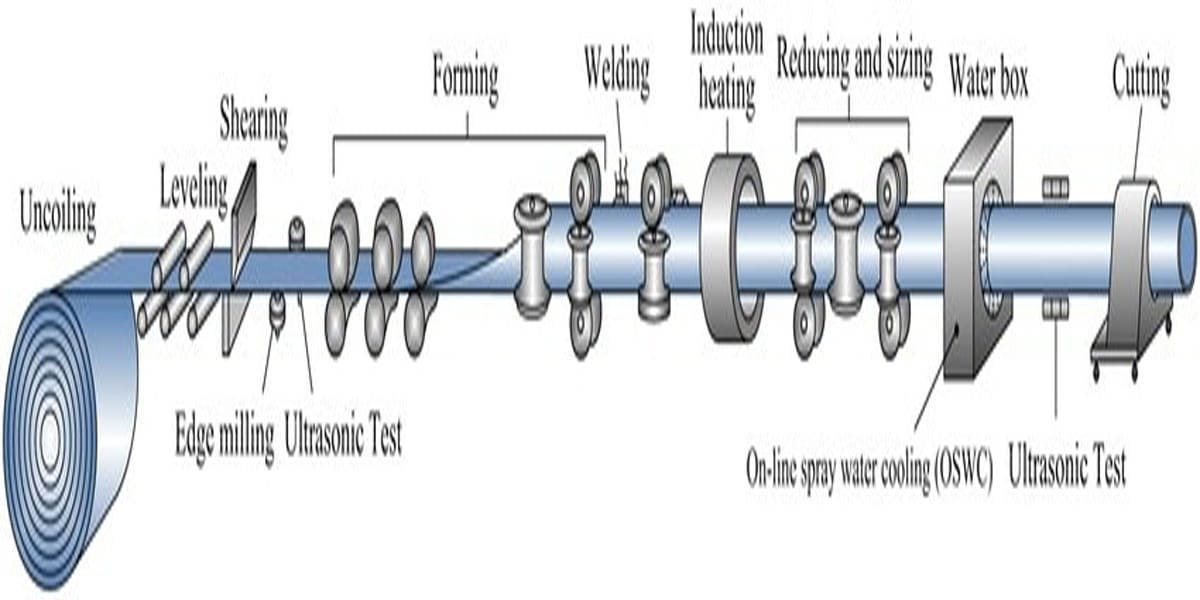

Manufacturing Process:

Raw Material Preparation: Steel coils or strips are prepared by cutting, cleaning, and removing impurities to meet the required standards.

Forming: The steel strip is fed into a forming machine, where it is shaped into a round tube through a series of molds and rollers.

Welding: The electric resistance welding (ERW) process is used to weld the edges of the steel strip. The strip is heated using electrical current, and pressure is applied to bond the edges together along the longitudinal seam.

Cooling and Cutting: After welding, the pipe is rapidly cooled to stabilize its structure. It is then cut to the desired length.

Quality Inspection: The finished pipes undergo quality checks, including visual inspections, dimensional checks, and pressure tests to ensure compliance with industry standards.

Surface Treatment: Depending on the application, ERW steel pipes can undergo surface treatments such as painting or galvanizing to improve corrosion resistance and extend their lifespan.

The ERW Steel Pipe manufacturing process is efficient and cost-effective, though strict control over welding quality and pipe strength is essential to ensure reliability and safety in various applications.

Advantages of ERW Steel Pipe

Cost-Effective: ERW steel pipes are generally more affordable to produce than other types of steel pipes, such as seamless pipes. The manufacturing process is efficient and requires fewer steps, reducing overall production costs.

High Strength: Despite the welding process, ERW steel pipes exhibit strong mechanical properties and can withstand high pressure, making them suitable for a variety of applications, including oil and gas transportation.

Customization: ERW steel pipes can be produced in a wide range of sizes, thicknesses, and lengths, offering flexibility to meet different project requirements. This makes them highly versatile for various industries.

Uniformity: The manufacturing process allows for precise control over dimensions and thickness, resulting in high-quality pipes with consistent properties, including wall thickness and diameter.

Efficient Production: The ERW manufacturing process is fast and automated, enabling high production rates with fewer resources. This makes it ideal for large-scale projects with high demand for steel pipes.

Durability: ERW steel pipes, particularly those that undergo surface treatments like galvanizing or coating, are resistant to corrosion and wear, increasing their lifespan and suitability for harsh environments.

Wide Application Range: ERW steel pipes are used in a broad spectrum of industries, from construction and infrastructure to oil and gas, providing reliable solutions for pipelines, structural applications, and more.

Environmental Benefits: The production of ERW steel pipes is relatively energy-efficient compared to other methods like seamless pipe production, leading to lower environmental impact and reduced carbon footprint.

Choosing the Right ERW Steel Pipe Supplier & Manufacturer

1. Market Positioning

When selecting the right ERW steel pipe supplier and ERW steel pipe manufacturer, it’s essential to first understand their market positioning to ensure their products and services meet the specific needs of your project. Different suppliers and manufacturers may focus on different market segments, and here are some key factors:

Product Application Areas: Some ERW steel pipe manufacturers may focus on the high-end market, offering premium ERW carbon steel pipes for harsh environments in industries like oil, gas, and chemicals, while others may cater to construction and infrastructure markets, offering more cost-effective products.

Production Scale and Market Coverage: Larger ERW steel pipe suppliers are typically capable of meeting large-scale procurement needs, suitable for large projects. Smaller suppliers may be more suited to custom orders or small batch production.

Price Range and Positioning: Different ERW steel pipe manufacturers may set different price points. Some may focus on high-performance products, offering premium ERW steel pipes, while others focus on competitive pricing, offering cost-effective options.

2. Choosing the Right ERW Steel Pipe Supplier

A suitable ERW steel pipe supplier should possess the following characteristics:

Reliable Quality and Certifications: Choose suppliers that hold international quality certifications (such as ISO 9001) and industry-standard certifications (like API 5L) for their ERW steel pipes, ensuring they meet high-quality and safety standards.

Competitive Pricing and Delivery Capabilities: The ERW steel pipe supplier should offer reasonable prices and ensure timely delivery, particularly for large orders, while managing the production cycle of ERW steel pipe manufacturing.

Technical Support and After-Sales Service: A good supplier should offer technical consultation and support, especially when issues arise with the ERW steel pipes during application. Timely after-sales service helps resolve issues and prevents project delays.

Environmental Responsibility: The supplier should comply with environmental regulations and provide products that align with sustainable development practices, which is especially important for projects focused on green building.

3. Choosing the Right ERW Steel Pipe Manufacturer

When selecting an ERW steel pipe manufacturer, it’s crucial to assess their production capacity and technical expertise:

Manufacturing Process and Technological Innovation: Ensure the manufacturer uses modern production equipment and technology, capable not only of producing high-quality ERW steel pipes, but also of meeting custom needs. The innovation capacity of the ERW steel pipe manufacturing process determines whether they can provide tailored products for specific requirements.

Production Capacity and Delivery Time: For large projects or long-term collaborations, a manufacturer’s production capacity and timely delivery are critical. Make sure they have the ability to handle large orders and deliver products within the agreed timeframe.

Quality Inspection and Control: High-quality ERW steel pipes require strict quality control systems. Choose a manufacturer with a comprehensive quality inspection system to ensure the pipes meet standards.

Industry Experience and Reputation: Opt for ERW steel pipe manufacturers with extensive industry experience and a strong reputation. This helps ensure the reliability and stability of their products.

4. Key Collaboration Points with ERW Steel Pipe Suppliers

Establishing a strong working relationship with an ERW steel pipe supplier is key to the success of long-term projects. Here are some key points for successful collaboration:

Clear Communication and Requirement Alignment: At the beginning of the collaboration, clearly define project requirements, including pipe specifications, quantities, and delivery timelines. This ensures the ERW steel pipe supplier can provide the right products and services based on specific needs.

Regular Quality Inspections and Follow-ups: During the collaboration, perform regular quality checks of the ERW steel pipes and provide feedback on any issues. Timely resolution of issues helps prevent delays in the project schedule.

Building Long-Term Partnerships: Choose suppliers that offer the potential for long-term collaboration. This enables you to negotiate better terms regarding price, quality, and delivery conditions, while reducing procurement risks.

Flexibility in Response to Market Changes: Market demands, prices, and other factors may change over time. Having flexible supply agreements ensures that the ERW steel pipe manufacturer can adjust to market shifts, keeping the project stable.

Technical Support and After-Sales Service: Ensure the ERW steel pipe supplier provides solid technical support and after-sales services. Especially when facing quality issues or urgent requirements, having prompt assistance is crucial for project success.

Applications of ERW Steel Pipes

ERW (Electric Resistance Welded) steel pipes are widely used across various industries due to their excellent mechanical properties, corrosion resistance, and efficient manufacturing process. Below are the key application areas of ERW steel pipes:

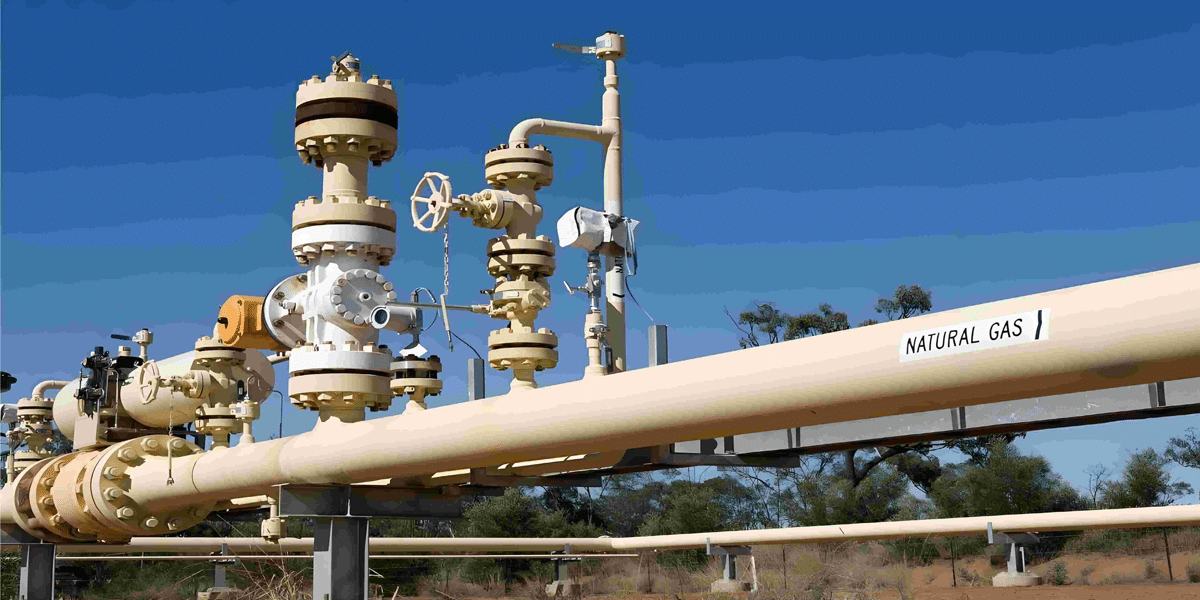

1. Oil and Gas Industry

Pipeline Transport: ERW steel pipes are commonly used in long-distance transportation pipelines for oil and gas, particularly in pipeline construction for oil and gas fields, offering strong corrosion resistance and high-pressure endurance.

Casing and Production Tubing: ERW steel pipes are also used in oil well operations for casing and production tubing, ensuring stable performance under extreme conditions.

2. Construction and Infrastructure

Structural Tubing: ERW steel pipes are widely used in construction for structural support, frames, and bridge structures, particularly where high strength and durability are required.

Building Steel Pipes: In building projects, such as skyscrapers, towers, and subways, ERW steel pipes are used as load-bearing and support components.

Scaffolding Tubes: ERW steel pipes are also employed in scaffolding systems in construction, supporting workers and materials during the building process.

3. Transportation

Automotive Industry: ERW steel pipes are used in automotive manufacturing for car frames, exhaust pipes, steering tubes, and other parts. Their lightweight yet high-strength properties make them an ideal choice.

Rail and Aerospace: ERW steel pipes are used in the manufacturing of structural components and pipelines in rail transport and aerospace applications.

4. Water Treatment and Distribution Systems

Water and Sewer Pipes: ERW steel pipes are used in water supply and sewage systems, especially for large-volume transport and environments requiring high corrosion resistance.

Irrigation Systems: In agriculture, ERW steel pipes are used in irrigation systems to ensure the effective delivery of water resources.

5. Heating and Cooling Systems

Heating Pipes: In the heating industry, ERW steel pipes are used in the transport of hot water or steam, supporting heating systems for residential, industrial, and city-wide applications.

Cooling Systems: ERW steel pipes are widely used in industrial cooling systems to maintain the temperature of machinery and equipment within safe limits.

6. Power Industry

Power Transmission Pipelines: ERW steel pipes are used in electrical infrastructure for cable conduits, ensuring the safe and stable transport of cables and lines.

7. Machinery Manufacturing

Mechanical Components: ERW steel pipes are utilized in the manufacturing of various machinery parts, including structural components and hydraulic system tubing, providing strength and toughness.

8. Chemical Industry

Reactors and Piping: ERW steel pipes are used in chemical plants as transport pipelines for various chemicals, liquids, and gases, particularly in high-temperature and high-pressure environments.

Quality Control and Standards of ERW Steel Pipes

To ensure that ERW (Electric Resistance Welded) steel pipes maintain excellent mechanical properties and reliability, strict quality control and adherence to international standards throughout the manufacturing process are essential. Below are the key aspects of quality control and the common standards for ERW steel pipes:

1. Quality Control Process for ERW Steel Pipes

Raw Material Inspection: The first step in quality control involves inspecting the steel coils or strips. Ensuring that the raw materials meet the required chemical composition and mechanical property specifications is crucial for the desired performance during subsequent processing.

Welding Quality Control: The electric resistance welding process is a critical step in ERW steel pipe manufacturing. Parameters such as temperature, pressure, and current are monitored in real-time to ensure the quality of the weld joint. Defects like porosity, cracks, or incomplete welding must be detected and addressed immediately.

Dimensional Inspection: The external diameter, wall thickness, and length of the ERW steel pipes must meet design specifications. Online dimensional monitoring techniques, such as laser measurement and ultrasonic testing, are used during production to ensure uniformity and precision.

Mechanical Property Testing: Tensile, hardness, and impact tests are conducted to assess the mechanical properties of ERW steel pipes and ensure they meet the performance requirements. Key quality indicators include tensile strength, yield strength, and elongation.

Corrosion Resistance Testing: Surface quality plays a crucial role in the corrosion resistance of steel pipes. During production, surface inspection and anti-corrosion treatments are performed to ensure that the product can withstand harsh environmental conditions.

Non-Destructive Testing: Common non-destructive testing methods include ultrasonic testing, X-ray inspection, and magnetic particle testing to check for internal and surface defects, ensuring that each pipe meets the required specifications.

2. Common Standards for ERW Steel Pipes

The production and testing of ERW steel pipes must comply with relevant industry standards. Below are some commonly applied standards:

ISO 9001 Quality Management System: This globally recognized quality management standard ensures that ERW steel pipe manufacturers follow international quality management practices during production.

API 5L: This standard, set by the American Petroleum Institute, covers technical specifications for pipes used in the transportation of oil and natural gas, particularly for long-distance pipelines, and is relevant for ERW steel pipes.

ASTM A53: A standard by the American Society for Testing and Materials (ASTM) covering specifications for ERW steel pipes used in general construction, industrial, and other applications.

ASTM A500: This standard applies to structural ERW steel pipes used in building construction, bridges, and other structural applications.

EN 10219: This European standard specifies technical requirements for cold-formed welded steel pipes for structural and non-structural applications, widely applied in the European market.

JIS G 3445: The Japanese Industrial Standard covering pipes used for mechanical and general engineering applications, relevant for ERW steel pipe manufacturing.

3. Other Quality Control Requirements

Surface Quality: The surface of ERW steel pipes must be smooth and free from defects. Severe oxidation, scratches, or cracks are not allowed. Surface treatments (e.g., coating or galvanizing) are also essential for preventing corrosion.

Packaging and Transportation: After passing quality control and inspection, ERW steel pipes are packaged according to standards to prevent damage during transportation. Typically, anti-corrosion materials are used for wrapping, and product information is clearly marked.

Traceability: Each batch of ERW steel pipes should be traceable to the raw material source, production date, and quality test reports, ensuring product quality throughout its lifecycle.

4. Quality Assurance System

Throughout the manufacturing process, ERW steel pipe manufacturers typically establish a quality assurance system that includes strict monitoring of production processes, quality control during raw material procurement, inspection of operational procedures, and final testing of finished products. These measures ensure that every ERW steel pipe meets design requirements and satisfies customer needs.

Market Trends and Future Outlook of ERW Steel Pipes

The ERW (Electric Resistance Welded) steel pipe market has been evolving rapidly, driven by factors such as increasing global demand, technological advancements, and a growing emphasis on environmental sustainability. Below are key aspects of market trends and the future outlook for ERW steel pipes:

1. Global Demand Growth

Rising Infrastructure Investments: The demand for ERW steel pipes has been experiencing a significant boost, especially in developing regions. Countries with rapidly growing infrastructure, such as India, China, and parts of Africa, are expected to drive the market forward. The increasing need for transportation pipelines in the oil, gas, and water sectors is contributing to the high demand for durable and cost-effective steel pipes.

Oil and Gas Sector Expansion: The ongoing global demand for energy and the expansion of oil and gas exploration projects, including deep-sea drilling and shale gas, further drive the need for ERW steel pipes. These pipes are essential for transporting oil, natural gas, and other fluids over long distances, particularly in regions with challenging environments.

Urbanization and Construction Boom: As urbanization accelerates worldwide, particularly in emerging markets, the demand for ERW steel pipes in the construction sector is expanding. Steel pipes are increasingly being used for structural components, scaffolding, water supply, and sewage systems, contributing to the growing demand for these products.

2. Technological Innovation and New Products

Advances in Welding Technology: Technological advancements in welding processes, such as the development of high-frequency induction welding, have enhanced the quality and efficiency of ERW steel pipe manufacturing. These innovations have allowed for greater precision, improved weld strength, and reduced production costs, making ERW steel pipes even more competitive in various industries.

Smart and Customized Steel Pipes: With the growing demand for tailored solutions, manufacturers are now offering customized ERW steel pipes with specific mechanical properties and coatings. New product developments in corrosion-resistant coatings, heat-treated pipes, and high-strength materials are meeting the specialized requirements of industries like oil and gas, chemical processing, and construction.

Automation and Digitalization: The introduction of automation and digital technologies in the production of ERW steel pipes is improving manufacturing efficiency and consistency. Smart sensors, real-time data monitoring, and artificial intelligence are being used to optimize production processes, improve quality control, and reduce waste.

3. Environmental and Sustainability Focus

Eco-Friendly Manufacturing Practices: The increasing global focus on environmental protection is pushing ERW steel pipe manufacturers to adopt greener practices. Energy-efficient production methods, reduced carbon emissions, and the use of sustainable raw materials are gaining prominence. Companies are also investing in technologies that minimize waste and improve resource efficiency during production.

Recycling and Reuse of Steel: The use of recycled steel in ERW steel pipe manufacturing is growing as part of a larger industry trend toward sustainability. Many manufacturers are embracing the circular economy model, where old steel pipes are recycled to create new ones, reducing the need for virgin raw materials and lowering environmental impact.

Sustainable Product Development: The growing concern for sustainability has also influenced product development. ERW steel pipes with enhanced corrosion resistance, long-lasting coatings, and improved durability contribute to reducing maintenance and replacement costs over time, making them more sustainable in the long run.

4. Regulatory and Market Dynamics

Stricter Environmental Regulations: As global governments implement more stringent environmental regulations, especially concerning CO2 emissions and waste management, ERW steel pipe manufacturers are focusing on compliance. Adapting to these regulations will drive the demand for environmentally friendly manufacturing processes and greener products.

Shift in Consumer Preferences: Consumers are becoming more conscious of sustainability, and industries are increasingly seeking products that are eco-friendly and have a longer lifecycle. This shift is encouraging ERW steel pipe manufacturers to innovate and offer products that align with these sustainability goals.

5. Future Outlook

Market Expansion in Emerging Economies: The global market for ERW steel pipes is expected to continue its growth, particularly in emerging economies where infrastructure development and industrialization are rapidly progressing. Countries like China, India, and the Middle East are likely to remain key players in the demand for ERW steel pipes, with significant investments in oil, gas, water infrastructure, and construction projects.

Focus on High-Performance Products: As industries demand more specialized applications, there will be a greater emphasis on high-performance ERW steel pipes. Pipes with superior mechanical properties, corrosion resistance, and specific coatings will be in high demand, especially in industries such as oil and gas, chemicals, and construction.

Integration of Green Technologies: The future of ERW steel pipe manufacturing will likely be shaped by the integration of green technologies. From energy-efficient production methods to the use of sustainable materials, these innovations will be crucial in meeting the demands of an increasingly environmentally conscious market.

How to Choose the Right ERW Steel Pipe Supplier?

Selecting the right ERW (Electric Resistance Welded) steel pipe supplier is crucial for ensuring high-quality products and smooth project execution. Below are the key factors to consider when choosing an ERW steel pipe supplier:

1. Supplier Reputation and History

Market Reputation: It is important to choose an ERW steel pipe supplier with a good reputation. You can assess the supplier’s performance in the market by reviewing customer feedback, industry reviews, and past collaborations.

Industry Experience: Suppliers with years of experience are more likely to provide stable product quality and competitive pricing. Choosing an experienced supplier reduces the risk of product defects and supply interruptions.

2. Product Quality and Certifications

Compliance with Standards: Ensure that the ERW steel pipes provided by the supplier meet relevant international standards (such as ASTM, API, ISO, etc.). This directly affects the quality and performance of the products.

Quality Testing and Certifications: Check the supplier’s quality control system and confirm whether they hold valid quality certifications (e.g., ISO 9001). Also, ensure that the supplier conducts strict product testing and inspections to guarantee product quality.

3. Production Capacity and Lead Time

Production Scale and Capacity: The supplier’s production capacity impacts delivery timelines. Ensure that their manufacturing facilities are advanced and that they have sufficient capacity to meet your needs.

Lead Time and Responsiveness: Choose a supplier that can deliver on time and has a fast response time. Ensuring timely deliveries is critical to prevent project delays. Good communication and flexible supply arrangements are also essential to evaluate supplier reliability.

4. Customization and Technical Support

Customization Capabilities: Some industries may require customized ERW steel pipes (e.g., special sizes, corrosion-resistant materials, or high-strength properties). Choose a supplier that offers customization to meet your specific project requirements.

Technical Support and After-Sales Service: Consider whether the supplier provides technical consulting, installation support, and after-sales service. This is especially important for complex projects where technical expertise may be needed.

5. Pricing and Value for Money

Competitive Pricing: While price should not be the only deciding factor, a competitive price is important for controlling project costs. Comparing quotes from different suppliers helps evaluate the pricing competitiveness.

Long-Term Value: Select a supplier that offers high value for money. Even if their prices are slightly higher, if they provide superior quality, reliable service, and stable delivery, the investment is worthwhile in the long run.

6. Environmental and Sustainability Focus

Eco-Friendly Manufacturing Practices: With increasing environmental regulations, choosing a supplier that practices sustainable production methods is essential. This includes energy-efficient manufacturing, reduced carbon emissions, and using sustainable raw materials.

Sustainable Products: Learn whether the supplier offers ERW steel pipes that comply with environmental standards, such as using recyclable materials or low-energy production processes. This not only benefits the environment but also enhances your company’s image.

7. Supplier Location

Transportation Costs and Lead Time: The supplier’s location affects transportation costs and delivery time. If the supplier is far from your production site, transportation costs and lead time may increase, impacting overall efficiency.

Logistics and Delivery Capability: Choose a supplier with efficient logistics and timely delivery services to ensure that products arrive on schedule.

8. Risk Management and Contract Terms

Supply Risk Management: Ensure the supplier has contingency plans for unforeseen issues, such as raw material shortages or shipping delays. A reliable supplier should have backup plans to prevent disruptions in the supply chain.

Clear Contract Terms: Ensure that the supply contract clearly outlines product quality, delivery schedules, after-sales services, and dispute resolution mechanisms. This helps safeguard your interests and minimize potential risks.

In conclusion, choosing the right ERW steel pipe supplier is vital to ensuring the success of your projects and maintaining a reliable supply chain. By evaluating factors such as supplier reputation, product quality, production capacity, customization options, pricing, and sustainability practices, you can make an informed decision that aligns with your specific needs. Additionally, considering aspects like technical support, lead times, and risk management will help you build a long-term, mutually beneficial partnership. With the right supplier, you can ensure the consistent availability of high-quality ERW steel pipes that meet industry standards, while optimizing costs and project timelines. Ultimately, a thoughtful selection process will not only contribute to the immediate success of your projects but also provide lasting value for your business!