- 1. Overview of ASTM A500 and ASTM A252 Standards and Their Application Differences

- 2. Comparison and Analysis of the Steel Pipe Performance of ASTM A500 and ASTM A252

- 3. Differences in Manufacturing and Processing Performance Between ASTM A500 and ASTM A252 Steel Pipes

- 4. Comparison of Typical Application Scenarios of ASTM A500 and ASTM A252 Steel Pipes

- 5. Economic and Service Life Analysis of ASTM A500 and ASTM A252 Steel Pipes

In modern construction, infrastructure, and engineering projects, selecting the right steel pipe is crucial. ASTM A500 and ASTM A252 are two widely used standards in structural and foundation applications, each with distinct advantages. ASTM A500 is primarily used for structural support, emphasizing strength and dimensional accuracy, while ASTM A252 is designed for piling applications, focusing on durability and load-bearing capacity. As engineering projects demand higher material performance, a thorough comparison of ASTM A500 and ASTM A252 can help businesses make better choices in terms of strength, weldability, and cost-effectiveness, ensuring they meet the evolving needs of the industry!

Overview of ASTM A500 and ASTM A252 Standards and Their Application Differences

1. ASTM A500:

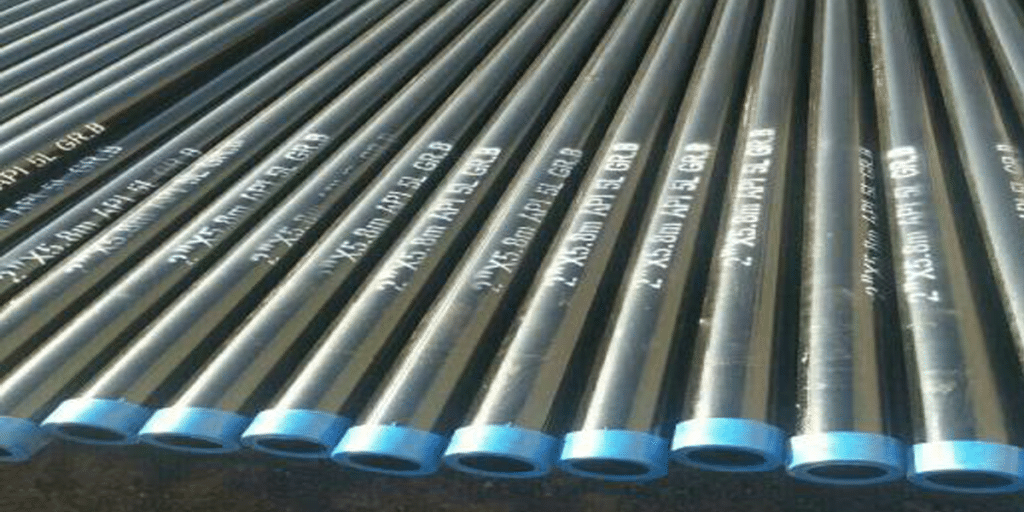

Standard Overview: ASTM A500 is the standard specification for cold-formed welded and seamless carbon steel structural tubing. It includes four grades (Grade A, B, C, and D), with Grade B and C being the most commonly used. The standard specifies minimum yield strength, tensile strength, chemical composition, and dimensional tolerances to meet structural engineering requirements.

Main Applications:

Structural Support: Used in building frameworks, bridges, and towers.

Mechanical Manufacturing: Applied in transportation systems, supports, and machine components.

Infrastructure Projects: Used in roads, railways, and tunnels for load-bearing structures.

2. ASTM A252:

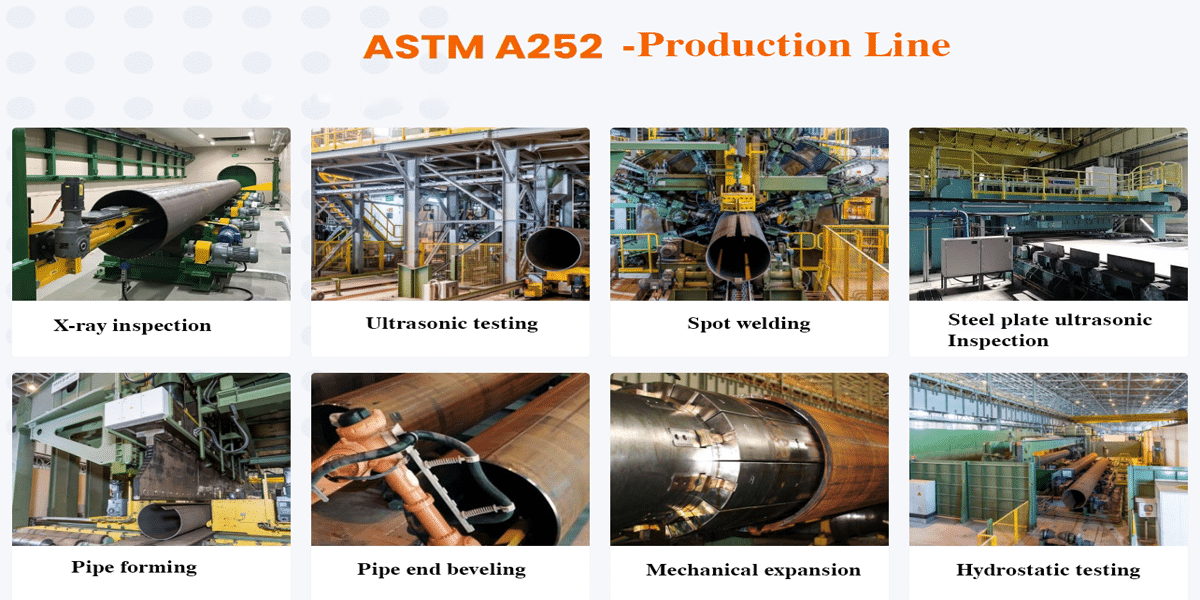

Standard Overview: ASTM A252 covers welded and seamless steel pipe piles for use in foundation applications. The focus of this standard is on load-bearing capacity and durability rather than strict chemical composition requirements. It primarily regulates yield strength and tensile strength to ensure stability in piling and foundation applications.

Main Applications:

Foundation Piling: Commonly used for bridge, dock, and building foundation piles.

Hydraulic and Marine Engineering: Applied in port breakwaters, offshore wind power foundations, etc.

Other Foundation Applications: Used in deep foundation support, retaining walls, and similar projects.

Comparison and Analysis of the Steel Pipe Performance of ASTM A500 and ASTM A252

1. Strength and Load-Bearing Capacity

ASTM A500: This standard specifies high yield and tensile strength requirements, making the steel pipe ideal for structural applications that require high strength and precision, such as in building frameworks, bridges, and towers. It is designed to withstand significant stress and pressure, ensuring the integrity of the structure.

ASTM A252: ASTM A252 focuses more on the load-bearing capacity for foundation applications. While it also ensures adequate strength, the primary concern is its ability to handle the heavy loads and stresses encountered during piling, especially in deep foundations or marine environments.

2. Dimensional Accuracy and Tolerances

ASTM A500: This standard is very strict about dimensional tolerances. Pipes must meet precise specifications for diameter, wall thickness, and length, ensuring that they fit seamlessly into structural designs that require high accuracy.

ASTM A252: The dimensional tolerance requirements are more lenient compared to ASTM A500. This is because the primary focus of ASTM A252 is the pipe’s ability to withstand the stresses associated with piling, where minor deviations in dimensions are less critical than in structural applications.

3. Chemical Composition and Material Quality

ASTM A500: The standard specifies detailed chemical composition requirements, including limits on carbon, manganese, phosphorus, sulfur, and other elements. These strict requirements help ensure the pipe’s overall quality, weldability, and resistance to corrosion in structural environments.

ASTM A252: The focus of ASTM A252 is less on chemical composition and more on ensuring the steel has the necessary strength and durability for piling applications. While material quality is still important, there are fewer restrictions on the exact chemical makeup, allowing for a broader range of material sources.

4. Welding and Fabrication

ASTM A500: Steel pipes made to ASTM A500 must have good weldability, which is crucial for their use in welded structural applications. The precise control over chemical composition ensures that welding processes will create strong and durable joints.

ASTM A252: Since ASTM A252 pipes are used for piling, their weldability is also important but not to the same degree as with ASTM A500. The pipes are typically used in conditions where welding is less frequent, and the primary concern is their ability to withstand the external environment and support the load.

5. Application Suitability

ASTM A500: Ideal for structural applications such as building frames, mechanical supports, and bridges where strength, precision, and dimensional accuracy are crucial for overall performance. It is commonly used in the construction of frames and supports in both commercial and industrial settings.

ASTM A252: Best suited for piling and foundation projects, particularly in deep foundations, bridges, docks, and marine environments. Its design is tailored to meet the demands of handling heavy vertical loads and exposure to harsh environmental conditions, making it the go-to choice for foundation work in various industries.

6. Durability and Environmental Resistance

ASTM A500: While ASTM A500 pipes are designed for structural integrity, their exposure to external environmental factors (such as corrosion or extreme weather) is not as much of a focus as with ASTM A252. However, with appropriate coatings, these pipes can be made resistant to environmental degradation.

ASTM A252: Durability is a key characteristic of ASTM A252 pipes, especially in terms of their ability to resist corrosion and wear in marine or underground environments. Since these pipes are often used in aggressive conditions, they are designed to withstand prolonged exposure to soil, water, and other environmental factors.

7. Cost Consideration

ASTM A500: Due to its stringent requirements for strength, accuracy, and material quality, ASTM A500 pipes tend to be more expensive than ASTM A252 pipes. The costs are justified by the need for high-quality structural materials in applications that require precision and reliability.ASTM A252: Generally.

ASTM A252 pipes are more cost-effective due to the less stringent requirements for dimensional accuracy and material composition. They are typically used for larger-scale projects where the emphasis is on load-bearing capacity rather than fine tolerances or surface finish.

Differences in Manufacturing and Processing Performance Between ASTM A500 and ASTM A252 Steel Pipes

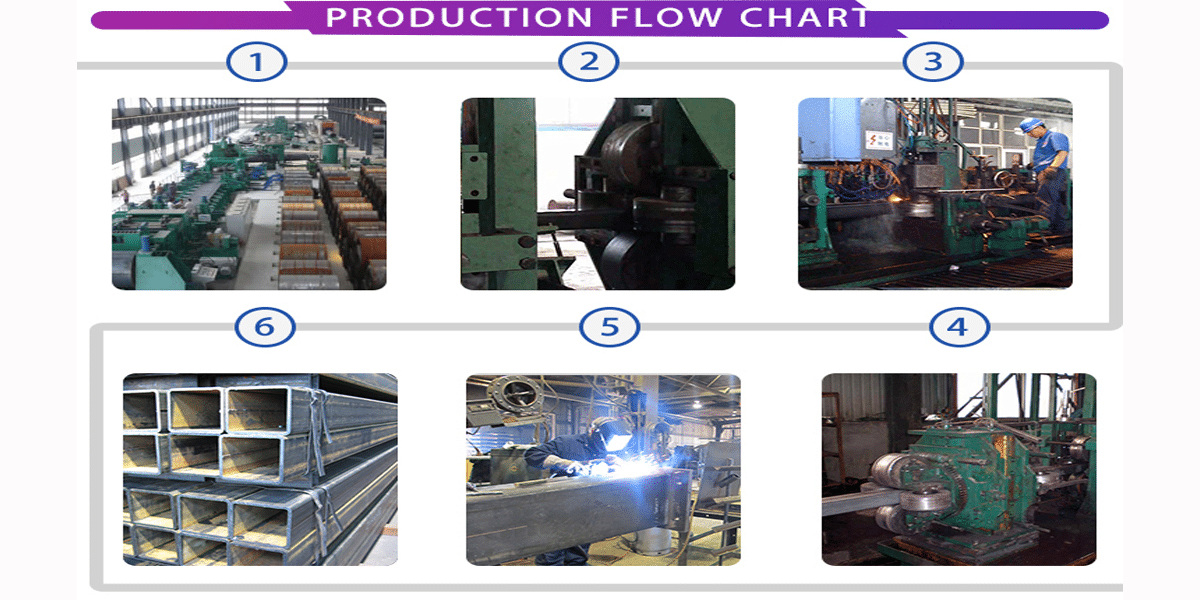

1. Manufacturing Process

ASTM A500: The ASTM A500 standard applies to cold-formed, welded or seamless steel pipes. The manufacturing process often involves controlled forming and welding techniques to achieve precise dimensional accuracy. The process is typically more complex, requiring advanced machinery to meet tight tolerances, particularly for structural applications where precision is crucial.

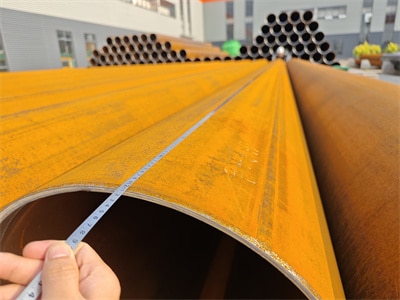

ASTM A252: ASTM A252 pipes can be welded or seamless, but the focus is on the pipe’s strength and ability to bear loads. The manufacturing process for ASTM A252 is generally simpler compared to ASTM A500, as the pipes do not need to meet the same stringent tolerances. While some dimensional control is necessary, the primary concern during production is the strength and durability of the material rather than exact dimensions.

2. Welding and Joining

ASTM A500: Due to its stringent requirements for strength and precise material composition, ASTM A500 steel pipes are designed with excellent weldability. The controlled chemical composition ensures that the material behaves predictably during welding, producing strong and durable welds that are essential for structural applications. Welders can achieve high-quality joints with minimal risk of defects.

ASTM A252: While ASTM A252 pipes also need to be weldable, the welding process for these pipes can be more forgiving due to the less strict dimensional and material requirements. However, the welding process may need to consider external factors like corrosion resistance, especially in marine or underground applications. The focus is on ensuring that the welds can hold under heavy loads and harsh environmental conditions.

3. Forming and Shaping

ASTM A500: The forming process for ASTM A500 pipes requires precision due to the need for tight tolerances. Cold forming and controlled welding ensure that the final product meets strict criteria for dimensional accuracy. This is critical for structural applications where pipes must fit precisely into frameworks or mechanical systems.

ASTM A252: Forming for ASTM A252 is less focused on dimensional accuracy, as the pipes are primarily designed to bear loads rather than fit into intricate structures. The shaping process may involve less control over tolerances compared to ASTM A500, as the pipes are typically used in large-scale piling or foundation projects, where minor deviations do not significantly impact performance.

Comparison of Typical Application Scenarios of ASTM A500 and ASTM A252 Steel Pipes

1. Typical Applications of ASTM A500 Steel Pipe

Structural Engineering: ASTM A500 steel pipes are widely used in structural engineering, particularly in applications requiring high strength and precise dimensional control. They are commonly used in frame structures, floor supports, bridges, and steel buildings. Due to their superior mechanical properties and dimensional accuracy, ASTM A500 steel pipes are often used in high-rise buildings, bridges, and other structures that demand strength and safety.

Mechanical and Industrial Equipment: ASTM A500 steel pipes are also used in mechanical manufacturing and industrial equipment, such as support frames, robotic arms, and equipment frameworks. These applications require pipes with excellent durability and strength under load, and precise dimensional control is essential.

Transportation and Logistics Facilities: In transportation and logistics facilities, ASTM A500 steel pipes are used as load-bearing parts in structures like transport bridges, storage racks, and elevated roadways. These facilities require strong, stable, and safe structural components, and ASTM A500 pipes meet these requirements with their strength and structural stability.

2. Typical Applications of ASTM A252 Steel Pipe

Pile Foundation Engineering: ASTM A252 steel pipes are primarily used for piling and foundation construction. They are commonly employed as piling pipes in deep foundation works such as foundation piles, bridge piles, tunnel piles, and dam piles. Due to their high bearing capacity and corrosion resistance, ASTM A252 steel pipes are well-suited for use in complex underground environments, where they can withstand significant pressure and loads.

Underground Construction and Subsea Projects: ASTM A252 steel pipes are widely used in underground facilities such as subways, underground pipelines, and tunnels. These projects require steel pipes with high strength, durability, and corrosion resistance, and ASTM A252 pipes are ideal for these applications, providing the necessary load-bearing capacity and environmental adaptability for long-term underground usage.

Marine Engineering: In marine projects such as offshore oil and gas extraction, offshore platforms, and wind power projects, ASTM A252 steel pipes are commonly used as support piles and structural pipelines. These applications require excellent corrosion resistance and high load-bearing capacity, both of which ASTM A252 steel pipes provide, making them ideal for harsh offshore environments.

Water Infrastructure: ASTM A252 steel pipes are also used in water infrastructure projects like dams, water channels, and irrigation pipelines. These applications require pipes with strong durability and resistance to corrosion, which ASTM A252 steel pipes offer, ensuring reliable performance in water management systems.

Economic and Service Life Analysis of ASTM A500 and ASTM A252 Steel Pipes

1. Economic Analysis of ASTM A500 Steel Pipe

Initial Cost: ASTM A500 steel pipes generally have a higher initial cost compared to ASTM A252 steel pipes due to the precision and strength required in their manufacturing. The pipes are often subjected to more stringent quality controls and dimensional accuracy requirements, which can increase production costs.

Maintenance and Durability: The high strength and precise dimensions of ASTM A500 steel pipes make them highly durable and resistant to mechanical damage in structural applications. This means that over time, these pipes may require less maintenance in environments where mechanical stress and structural integrity are paramount. This reduces long-term maintenance costs, making them cost-effective over the pipe’s lifecycle.

Long-Term Value: The long-term value of ASTM A500 steel pipes is found in their high durability and structural performance, which often lead to longer-lasting structures. While the initial investment may be higher, their minimal maintenance and reliable performance provide good economic returns in projects with high safety and strength demands.

2. Economic Analysis of ASTM A252 Steel Pipe

Initial Cost: ASTM A252 steel pipes generally have a lower initial cost compared to ASTM A500. These pipes are designed primarily for piling and foundation applications, where dimensional precision is less critical. Consequently, the production process is simpler and more cost-effective, leading to lower material and manufacturing costs.

Maintenance and Durability: ASTM A252 steel pipes are designed for use in environments with exposure to moisture, soil, and harsh underground conditions. While they offer excellent corrosion resistance, particularly in buried or submerged applications, their maintenance needs can be higher due to the demanding nature of the environments they are exposed to. The need for protective coatings and potential corrosion mitigation can increase maintenance costs over time.

Long-Term Value: The long-term value of ASTM A252 steel pipes lies in their ability to withstand harsh environments, such as underwater or underground conditions. Although maintenance may increase in some applications, their durability in these extreme environments justifies the cost, making them a viable option for projects like piling, foundations, and subsea infrastructure.

3. Service Life Comparison

ASTM A500 Steel Pipe Service Life: ASTM A500 steel pipes are typically used in structural applications, where they are exposed to mechanical loads and various environmental conditions. The service life of ASTM A500 pipes can be extensive due to their high strength and resistance to mechanical wear and fatigue. However, their exposure to corrosion depends on the environment, which may require additional protective measures like coatings or galvanization for extended use in harsh conditions. Typically, ASTM A500 pipes have a service life of 50+ years when properly maintained and protected.

ASTM A252 Steel Pipe Service Life: ASTM A252 steel pipes are primarily used for piling and foundation applications, often buried underground or submerged in water. These pipes are designed to withstand pressure, corrosion, and other harsh environmental conditions, which can extend their service life significantly in such settings. With proper corrosion protection and maintenance, ASTM A252 pipes can also last for several decades, often exceeding 50 years in applications like water infrastructure and marine engineering.

ASTM A500 and ASTM A252 serve distinct purposes—A500 excels in structural applications requiring strength and precision, while A252 is ideal for foundation and piling projects with high load-bearing demands. Economically, A500 has a higher initial cost but lower maintenance, whereas A252 is cost-effective upfront but may require corrosion protection. Choosing the right steel pipe depends on project needs, balancing performance, durability, and cost!