- 1. Overview of ASTM A671, A672, and A691 Steel Pipes

- 2. Safety Standards of ASTM A671, A672, and A691 Steel Pipes in Multinational Projects and Their Complexity in Projects

- 3. Challenges Faced by ASTM A671, A672, and A691 Steel Pipes in Multinational Projects and How to Maintain System Stability

- 4. Quality Control and International Certification Standards for ASTM A671, A672, and A691 Steel Pipes

- 5. Future Outlook and Market Trends of ASTM A671, A672, and A691 Steel Pipes

With the advancement of globalization, energy, infrastructure, and industrial projects are increasingly being carried out across borders. Multinational projects often involve complex environmental conditions, stringent engineering standards, and diverse regional regulations, making the selection of high-performance steel pipes that meet international standards essential. ASTM A671, A672, and A691 steel pipes are widely used in sectors such as oil and gas transportation, power generation, offshore pipelines, and water treatment facilities due to their exceptional pressure resistance, corrosion resistance, and reliability. This article explores real-world applications of these steel pipes in multinational projects, highlighting their advantages and significance in the global market!

Overview of ASTM A671, A672, and A691 Steel Pipes

1. ASTM A671 Steel Pipe

ASTM A671 is an Electric-Fusion-Welded (EFW) carbon and low-alloy steel pipe primarily designed for moderate- to low-temperature applications. This standard includes various grades of steel, each specified by its chemical composition and mechanical properties. Key features include:

Suitable for low-temperature and medium-pressure environments, such as water supply pipelines and petrochemical industry applications.

Undergoes Post-Weld Heat Treatment (PWHT) to enhance weld quality and overall durability.

Available in different steel grades and impact testing requirements to meet specific project needs.

2. ASTM A672 Steel Pipe

ASTM A672 is also an Electric-Fusion-Welded (EFW) steel pipe, but it is designed for high-temperature and high-pressure applications. Compared to A671, A672 pipes offer enhanced resistance to elevated temperatures and pressure, making them ideal for more demanding conditions. Key features include:

Used in high-temperature and high-pressure pipelines, such as steam pipelines, power plant boiler piping, and petrochemical industries.

Can be manufactured with different welding quality levels and non-destructive testing (NDT) requirements to ensure reliability.

Undergoes strict heat treatment processes to optimize material properties and enhance durability.

3. ASTM A691 Steel Pipe

ASTM A691 is a Submerged Arc-Welded (SAW) alloy steel pipe manufactured for extreme pressure and temperature environments. It is produced from alloy steel plates that are roll-formed and heat-treated to achieve superior mechanical strength. Key features include:

Designed for extreme high-pressure and high-temperature environments, such as refineries, energy transportation, and chemical processing plants.

Made from High-Strength Low-Alloy (HSLA) steel, improving creep resistance and corrosion resistance.

Subjected to strict quality control and testing, such as ultrasonic testing (UT) and radiographic testing (RT), to ensure defect-free welds.

Safety Standards of ASTM A671, A672, and A691 Steel Pipes in Multinational Projects and Their Complexity in Projects

How ASTM A671, A672, and A691 Steel Pipes Comply with International Standards?

1. Compliance with ASTM Standards: Manufacturing and Quality Control

ASTM (American Society for Testing and Materials) is a globally recognized organization for developing materials standards. ASTM A671, A672, and A691 steel pipes are produced in strict compliance with ASTM specifications to ensure material consistency and reliability.

2. Compliance with ASME, API, and Other Industry Standards

ASME (American Society of Mechanical Engineers) Standards:

These pipes comply with ASME B31.1 (Power Piping) and ASME B31.3 (Process Piping) standards, ensuring their stability in high-temperature, high-pressure environments.

They also adhere to ASME Section VIII (Pressure Vessels) for nuclear power plants and steam pipelines.

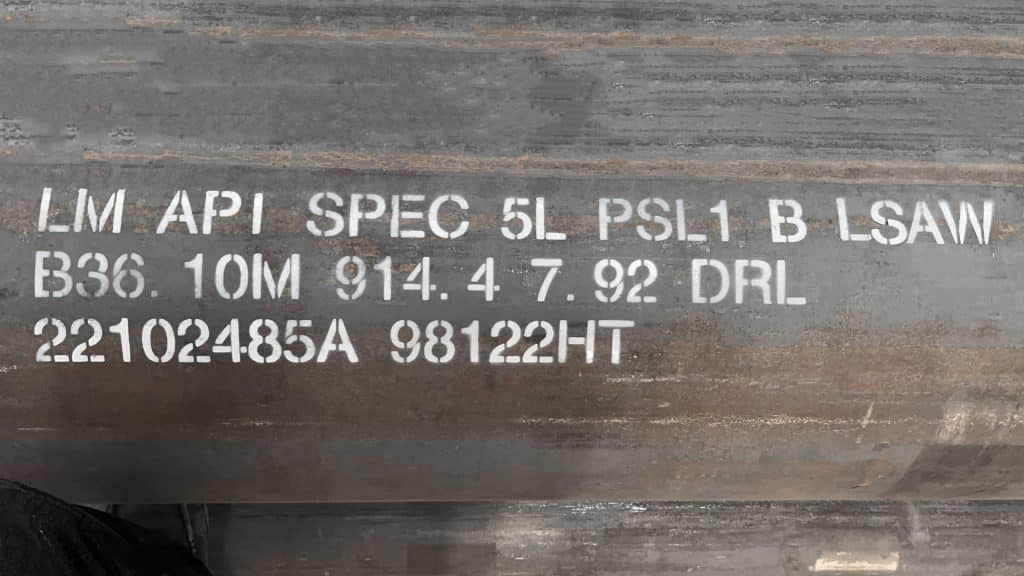

API (American Petroleum Institute) Standards:

ASTM A672 and A691 steel pipes comply with API 5L, which ensures their suitability for oil and gas transmission pipelines.

The API 5L standard requires the pipes to have high strength, good weldability, and corrosion resistance, making them ideal for cross-border oil and gas pipeline projects.

EN (European Norm) and ISO (International Organization for Standardization) Certifications:

These pipes meet EN 10217 (Welded Steel Pipes for Pressure Purposes) and ISO 3183 (Pipes for Petroleum and Natural Gas Industry) standards, ensuring compatibility with the European and international markets.

3. Quality Inspection and Nondestructive Testing to Ensure Safety

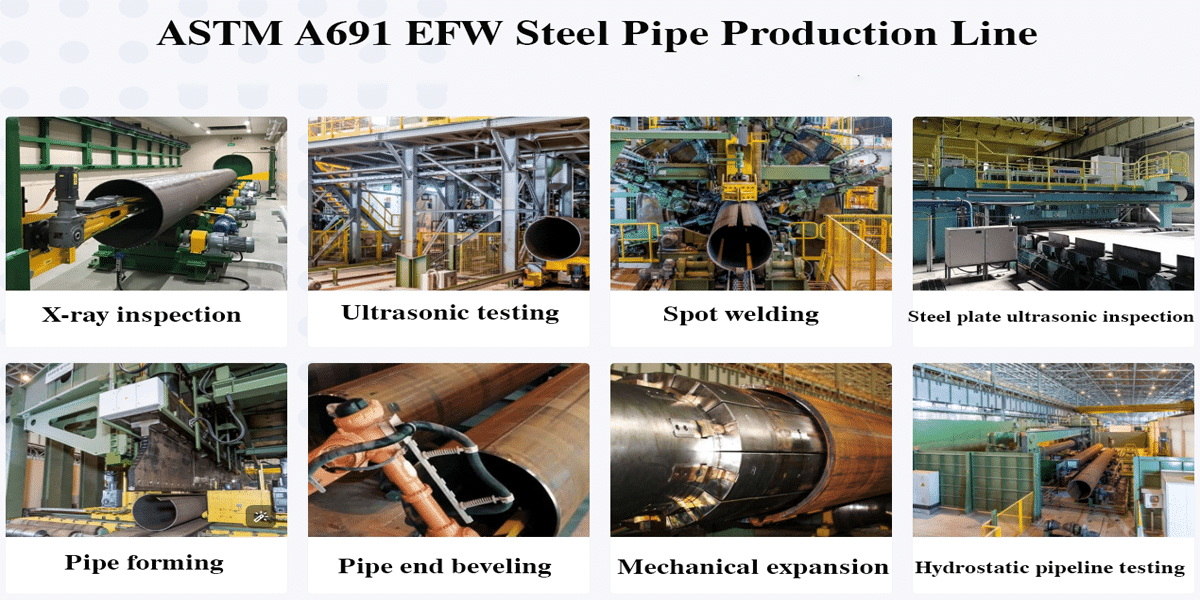

To guarantee safety, ASTM A671, A672, and A691 steel pipes undergo strict quality inspections and nondestructive testing (NDT) to detect material defects and enhance reliability.

Ultrasonic Testing (UT): Used to detect internal defects in welds and pipe walls to ensure pipe integrity.

Radiographic Testing (RT): X-ray or gamma-ray inspections are used to check weld quality and meet safety requirements.

Magnetic Particle Testing (MT) and Dye Penetrant Testing (PT): These methods help detect surface and near-surface defects, improving weld quality.

Impact and Tensile Testing: These tests simulate extreme conditions to ensure the pipes’ stability in low or high-temperature environments.

These inspections ensure that the pipes perform safely under harsh conditions and reduce potential operational risks.

4. Adapting to Safety Standards and Regulations in Multinational Projects

In North America, these pipes meet ASME, API, and CSA (Canadian Standards Association) standards, making them suitable for energy, oil, gas, and chemical sectors.

In Europe, they comply with EN and PED (Pressure Equipment Directive) certification requirements, making them suitable for boilers and pressure pipelines.

In the Middle East and Asia, these pipes are widely used in the petrochemical industry and water treatment projects, meeting local infrastructure needs.

Challenges Faced by ASTM A671, A672, and A691 Steel Pipes in Multinational Projects and How to Maintain System Stability

1. Material Compatibility and Environmental Conditions

Challenge: Multinational projects span different geographic locations, each with unique environmental conditions. Extreme temperatures, corrosion risks, and the presence of aggressive chemicals can affect the performance of steel pipes.

Solution:

ASTM A671, A672, and A691 steel pipes are designed to withstand high pressures and extreme temperatures, making them suitable for diverse environments.

To maintain stability, these pipes undergo advanced corrosion protection treatments and are coated with protective layers that ensure their resistance to corrosion in harsh climates (e.g., offshore or desert regions).

2. Adherence to Local Standards and Regulations

Challenge: Different countries and regions have distinct standards and regulatory requirements for materials used in infrastructure projects. Adapting to local standards can be complex and time-consuming.

Solution:

ASTM A671, A672, and A691 pipes are produced in compliance with global standards like ASTM, ASME, and API, and they can be customized to meet local codes and regulations.

Ensuring compatibility with various national regulations (e.g., European EN standards, American API norms, or Chinese GB standards) is crucial to ensure smooth integration into local projects.

3. Installation and Maintenance in Remote or Challenging Areas

Challenge: Multinational projects often involve challenging terrain, such as remote locations or offshore platforms, where installing and maintaining steel pipes becomes difficult.

Solution:

Weldability and durability: ASTM A671, A672, and A691 pipes are manufactured with excellent weldability and mechanical properties, allowing for easier installation even in difficult conditions.

For maintenance, these pipes are designed to be low-maintenance, with high resistance to wear and tear, reducing the need for frequent inspections or replacements in remote areas.

4. Pressure and Temperature Variability

Challenge: High-pressure and high-temperature variations in different parts of the pipeline can cause stress and damage to the steel pipes, leading to potential failures or inefficiencies in the system.

Solution:

A691 steel pipes are especially suited for high-pressure, high-temperature conditions, often seen in refining, petrochemical, and power generation plants.

By maintaining rigorous pressure testing and temperature tolerance assessments, these pipes ensure operational stability and reliability even in fluctuating conditions.

Case Studies of ASTM A671, A672, and A691 Steel Pipes in Multinational Projects

1. ASTM A671 Steel Pipe: Water Treatment Project in the Middle East

In a large-scale water treatment project in the Middle East, ASTM A671 steel pipes were used for transporting treated water across long distances. Due to the region’s harsh climate, which includes high temperatures and saltwater exposure, the project required corrosion-resistant and durable materials.

Application: The pipes were chosen for their excellent performance in low-temperature environments and their resistance to corrosion, ensuring that the water transportation system would operate efficiently without frequent maintenance.

Challenge: The extreme climate, with high salt levels in the air, posed a significant risk of accelerated corrosion. The ASTM A671 steel pipes were chosen for their high resistance to corrosion, making them the ideal choice for this project.

Outcome: The pipes performed well over time, ensuring the safe and reliable transportation of water, contributing to the project’s success.

2. ASTM A672 Steel Pipe: Power Plant in North America

In a power plant project in North America, ASTM A672 steel pipes were used for the transportation of steam and other high-temperature fluids within the plant. This project required pipes capable of withstanding high pressures and extreme temperatures due to the nature of the plant’s operations.

Application: ASTM A672 was selected because of its ability to handle high-pressure steam and gas, crucial for the power generation process. The pipes provided the necessary strength to ensure safe and efficient energy production.

Challenge: Maintaining safety under high-pressure and high-temperature conditions is critical in power plants, especially in a multinational project where different standards and regulations must be adhered to.

Outcome: The pipes met both the stringent local and international standards, ensuring the plant’s performance and long-term reliability, helping the project to stay on schedule and within budget.

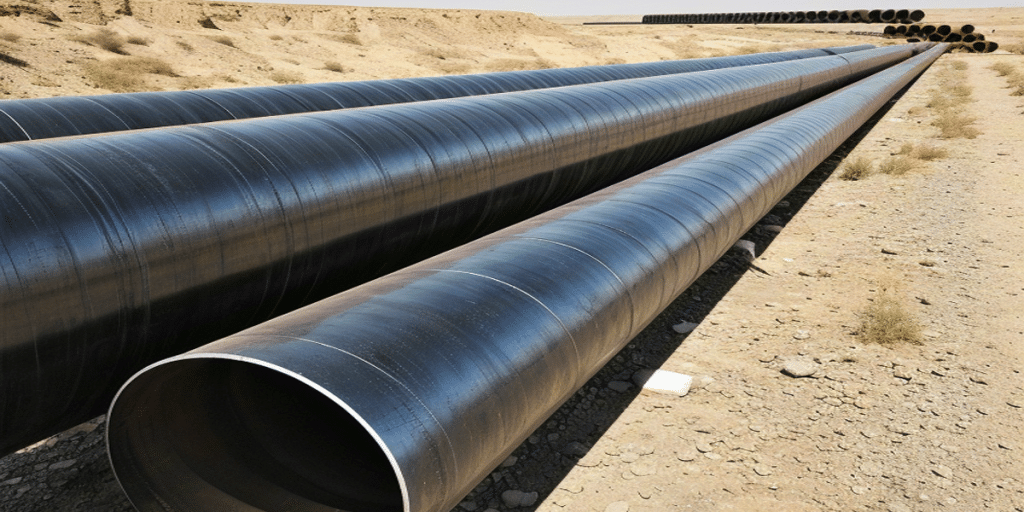

3. ASTM A691 Steel Pipe: Offshore Oil Platform in the North Sea

In a multinational project involving the construction of an offshore oil platform in the North Sea, ASTM A691 steel pipes were used for transporting oil and gas. The environment posed significant challenges due to high-pressure and corrosive seawater conditions.

Application: ASTM A691 steel pipes, known for their high strength and resistance to extreme temperatures and pressures, were ideal for transporting crude oil and gas from offshore wells to processing facilities.

Challenge: The North Sea’s harsh offshore environment required materials that could withstand extreme pressure, temperature fluctuations, and corrosion from seawater.

Outcome: The project successfully utilized ASTM A691 steel pipes, ensuring the safe and efficient transport of oil and gas. These pipes helped meet both local and international safety and environmental standards, contributing to the success of the offshore platform’s construction and operation.

Quality Control and International Certification Standards for ASTM A671, A672, and A691 Steel Pipes

1. Quality Control System

(1) Raw Material Inspection

The first step in producing ASTM A671, A672, and A691 steel pipes is selecting high-quality carbon steel or alloy steel, ensuring that the chemical composition meets ASTM specifications.

Optical Emission Spectroscopy (OES) or Direct Reading Spectroscopy is used to verify the chemical composition.

Metallographic analysis is conducted to examine the steel’s microstructure and ensure compliance with metallurgical requirements.

(2) Welding and Forming Process

ASTM A671 and A672 pipes are manufactured using electric arc welding, such as submerged arc welding (SAW), which provides a strong and uniform weld.

ASTM A691 pipes, designed for high-pressure and high-temperature applications, use multi-pass welding techniques to enhance strength and durability.

Non-destructive testing (NDT) is performed on welded seams to detect any imperfections or defects.

(3) Heat Treatment Process

Heat treatment, including normalizing, tempering, and stress relieving, is applied to refine the grain structure and improve the mechanical properties of the steel pipes.

Controlled furnace environments are used to maintain precise temperature settings, ensuring uniform material properties.

(4) Dimensional and Mechanical Testing

Pipes undergo dimensional inspections using laser measurement tools to ensure they meet specified diameter, wall thickness, and length tolerances.

Mechanical testing, such as tensile tests, impact tests, and hardness tests, verifies the strength, ductility, and toughness of the pipes.

(5) Hydrostatic and Pressure Testing

To ensure leak-proof performance, hydrostatic pressure testing is conducted by subjecting the pipes to water pressure levels exceeding their operational requirements.

Pipes designed for high-pressure applications (e.g., ASTM A691) undergo burst testing to confirm their resistance to extreme conditions.

(6) Surface Treatment and Corrosion Protection

Pipes are coated with anti-corrosion layers, including galvanization, epoxy coatings, and fusion-bonded coatings, to enhance their durability in harsh environments.

Ultrasonic thickness measurements ensure that the coatings meet required specifications.

2. How ASTM A671, A672, and A691 Steel Pipes Meet International Certification Standards?

1. Compliance with ASTM and ASME Standards

(1) ASTM Standards

ASTM A671: Covers electric-fusion-welded steel pipes for atmospheric and lower temperature service.

ASTM A672: Specifies electric-fusion-welded steel pipes for moderate temperature and high-pressure applications.

ASTM A691: Designed for high-pressure environments, using high-strength alloy steel with enhanced toughness and durability.

(2) ASME Boiler and Pressure Vessel Code (BPVC): For applications in high-temperature and high-pressure environments, ASTM A671, A672, and A691 pipes must comply with ASME BPVC Section II and Section VIII, ensuring their suitability for pressure vessel construction.

2. API 5L Certification for Oil and Gas Pipelines

High tensile strength and toughness, essential for long-distance pipeline transport.

Corrosion resistance and environmental stress tolerance, suitable for harsh conditions.

Seamless integration with global oil and gas infrastructure, meeting industry requirements.

API 5L-certified steel pipes are essential for cross-border oil and gas pipelines and offshore pipeline systems.

3. Compliance with ISO 3183 for International Pipeline Systems

ASTM A671, A672, and A691 steel pipes must pass chemical composition analysis, impact testing, and non-destructive testing to comply with ISO 3183.

This certification ensures compatibility with multinational pipeline projects that adhere to different national regulations.

4. Environmental and Safety Certifications (ISO & EU Standards)

(1) ISO 9001: Quality Management System

Strict quality control in manufacturing, guaranteeing product consistency and traceability.

Compliance with global trade requirements, facilitating exports to international markets.

(2) ISO 14001: Environmental Management System

Eco-friendly manufacturing processes, reducing carbon emissions and environmental impact.

Efficient waste management and resource recycling, meeting international environmental regulations.

(3) EU REACH Certification (Chemical Safety Compliance)

Ensure materials do not contain hazardous substances.

Meet strict European environmental and safety regulations, promoting sustainable development.

5. Non-Destructive Testing (NDT) and Additional Certifications

Ultrasonic Testing (UT) and Radiographic Testing (RT) to detect internal defects.

Magnetic Particle Testing (MT) and Dye Penetrant Testing (PT) for surface flaw detection.

Hydrostatic Pressure Testing to ensure pipes can withstand operational stress.

For projects that require additional verification, these steel pipes may also obtain certifications such as:

DNV (Det Norske Veritas) certification, essential for offshore and marine applications.

Lloyd’s Register certification, widely recognized in the global shipping and energy industries.

Future Outlook and Market Trends of ASTM A671, A672, and A691 Steel Pipes

1. Increasing Global Market Demand

(1) Driven by the Energy Sector

Oil & Gas Transportation: The expansion of cross-border oil and gas pipelines is driving the demand for high-strength, corrosion-resistant steel pipes, particularly in multinational oil and gas transmission projects.

Renewable Energy: With the development of emerging energy technologies such as hydrogen energy and carbon capture and storage (CCS), high-strength pipes like ASTM A691 will play a critical role in high-pressure transportation and specialized media handling.

(2) Infrastructure and Industrial Growth

Global Infrastructure Projects: Initiatives like the Belt and Road Initiative, cross-border water transfer, offshore engineering, and urban underground pipeline networks are increasing the demand for high-pressure and corrosion-resistant steel pipes.

Power Generation Industry: The growing number of thermal power, nuclear power, and combined heat and power (CHP) projects requires steel pipes such as ASTM A672 and A691 for high-temperature and high-pressure applications.

2. Advancements in Production Technology

(1) Development of High-Performance Materials

Optimized Alloy Composition: The use of high-strength low-alloy (HSLA) steel will become more widespread, improving pipe strength, heat resistance, and corrosion resistance while reducing material usage and costs.

Advanced Corrosion-Resistant Coatings: Innovations such as nano-coatings, thermal spray alloy layers, and internally lined alloy coatings will enhance pipe durability and extend service life.

(2) Automation and Smart Manufacturing

Intelligent Welding Technologies: Automated welding and robotic welding systems will improve weld quality, ensure consistency, and reduce human error, leading to higher production efficiency.

Digital Quality Control: With artificial intelligence (AI) and the Internet of Things (IoT), manufacturers can implement real-time monitoring of production data to enhance quality control and optimize manufacturing processes.

3. Sustainability and Environmental Considerations

(1) Low-Carbon Manufacturing Trends

Reducing Carbon Emissions: As countries push for carbon neutrality, steel manufacturers are adopting electric arc furnace (EAF) steelmaking, carbon capture technology (CCS), and green energy integration to reduce CO₂ emissions.

Circular Economy: The industry is moving towards increased recycling and resource efficiency to comply with global environmental regulations.

(2) Compliance with International Environmental Standards

With increasingly stringent global environmental regulations, ASTM A671, A672, and A691 steel pipes must comply with standards such as:

ISO 14001 (Environmental Management Systems)

EU REACH Certification (Regulation on Registration, Evaluation, Authorisation, and Restriction of Chemicals)

4. Market Competition and Industry Landscape Changes

(1) Globalized Supply Chains

The steel pipe supply chain is becoming more globalized, requiring manufacturers to enhance supply chain management to mitigate risks related to raw material price fluctuations, logistics challenges, and geopolitical factors.

International standard certifications (e.g., API 5L, ASME B31.3, ISO 3183) will be critical for companies seeking to expand into new markets.

(2) Increasing Industry Competition

Leading manufacturers will gain market advantages through technological innovation, brand influence, and customized high-end services.

More mergers, acquisitions, and strategic alliances are expected as companies seek to strengthen market competitiveness and expand production capacity.

ASTM A671, A672, and A691 steel pipes are essential for multinational projects, ensuring safety, durability, and compatibility through compliance with ASTM, ASME, API, ISO, and EU standards. These certifications guarantee high-quality manufacturing, environmental sustainability, and reliable performance in industries such as oil and gas, power generation, and infrastructure! As global demand for high-performance and eco-friendly materials grows, manufacturers will continue to enhance quality control, adopt advanced testing methods, and meet evolving international standards. With their proven reliability, ASTM A671, A672, and A691 steel pipes will remain a key choice for future cross-border energy and industrial projects!