- 1. Overview of ASTM A672 Steel Pipes

- 2. Applications of ASTM A672 Steel Pipes in the Energy Industry

- 3. High-Temperature and Corrosion Resistance of ASTM A672 Steel Pipes

- 4. Quality Control and Specification Selection for ASTM A672 Steel Pipes

- 5. Future Development and Application Prospects of ASTM A672 Steel Pipes

In the energy and power industries, the quality and durability of piping systems are of utmost importance. As a high-performance material with widespread applications, ASTM A672 steel pipes are indispensable due to their high strength, corrosion resistance, and excellent weldability. Whether in oil and gas transportation, cross-border pipeline systems, or cooling systems in the power industry, ASTM A672 steel pipes have proven their exceptional adaptability and reliability. In this article, we will explore the applications and advantages of ASTM A672 steel pipes in the energy and power industries!

Overview of ASTM A672 Steel Pipes

ASTM A672 steel pipes are high-strength, corrosion-resistant pipes designed for high-pressure transmission applications, widely used in industries such as oil, gas, chemicals, and power generation. This standard, established by the American Society for Testing and Materials (ASTM), is primarily intended for the manufacturing of welded steel pipes used in the transportation of oil, gas, and other fluids. These pipes are typically produced using the double-submerged arc welding (SAW) technique to ensure tight seals and structural integrity.

ASTM A672 steel pipes offer excellent pressure resistance and high-temperature capabilities, allowing them to withstand extreme conditions in harsh environments. In addition, their outstanding corrosion resistance makes them particularly suitable for long-term exposure to various chemical agents and extreme weather conditions. These properties make ASTM A672 steel pipes an ideal choice for applications such as oil and gas pipelines, offshore platforms, industrial pipeline systems, and cooling systems in power plants.

Applications of ASTM A672 Steel Pipes in the Energy Industry

ASTM A672 steel pipes are widely used in the energy industry due to their exceptional strength, corrosion resistance, and high-temperature performance. Particularly in the oil and gas transportation and power generation sectors, these pipes, with their outstanding physical and chemical properties, serve as essential infrastructure materials. Below are some of the primary applications of ASTM A672 steel pipes in the energy industry:

Oil and Gas Transportation Pipelines: ASTM A672 steel pipes are ideal for oil and gas transportation systems, especially for long-distance, high-pressure transmission requirements. Whether in land-based pipelines or subsea pipelines, ASTM A672 steel pipes can withstand extreme working pressures and environmental conditions, ensuring efficient and safe transportation of oil and gas from production sites to consumer markets.

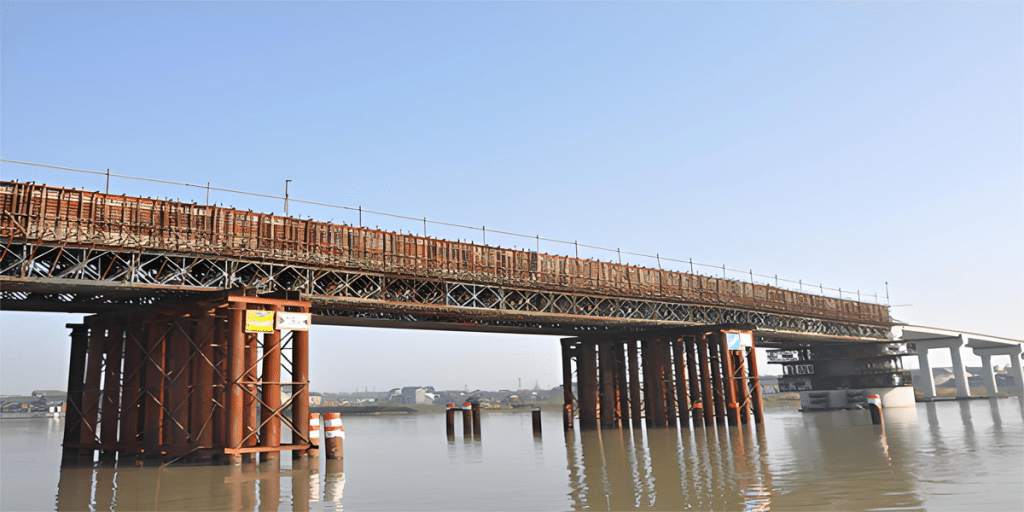

Cross-Border Pipeline Systems: With the growing global demand for energy, cross-border pipeline systems have become a critical component of the energy sector. The strength and corrosion resistance of ASTM A672 steel pipes make them highly advantageous in long-distance, high-risk transportation environments, effectively resisting external corrosion and ensuring the long-term stability of international pipeline systems.

Cooling Systems in the Power Industry: In the power industry, particularly in thermal power plants and nuclear power stations, cooling systems are crucial for maintaining the normal operation of equipment. Due to their excellent high-temperature resistance, ASTM A672 steel pipes are commonly used in power plant cooling water pipelines. These pipes can withstand high temperatures and pressures while resisting corrosion from waterborne chemicals, ensuring efficient operation of the cooling systems.

Offshore Platforms and Oil Drilling Pipelines: Offshore oil platforms and drilling operations require corrosion-resistant, high-pressure pipes. ASTM A672 steel pipes’ corrosion resistance and strength make them the ideal choice for offshore oil and gas exploration and development, providing stable operation in harsh marine environments and ensuring the safe extraction of oil and natural gas.

Energy Storage and Transmission Facilities: In energy storage and transmission processes, ASTM A672 steel pipes are used in pipelines for storing and transporting liquid energy. These pipes can endure extreme temperatures and corrosive substances, ensuring that energy is safely transported and stored without leakage or loss.

High-Temperature and Corrosion Resistance of ASTM A672 Steel Pipes

High-Temperature Resistance: ASTM A672 steel pipes are designed to perform reliably in high-temperature environments, especially under high-pressure conditions. Their material composition allows them to withstand temperature fluctuations and remain stable in environments such as cooling systems in thermal power plants and high-temperature transmission pipelines in oil refineries. These pipes can endure temperatures above 500°C, ensuring safe and stable operation of the systems.

Corrosion Resistance: The corrosion resistance of ASTM A672 steel pipes allows them to operate in harsh environments, especially in chemical media, seawater, and other corrosive environments. Their outstanding resistance to corrosion helps prevent leaks or damage caused by external corrosion, extending the lifespan of the pipeline. Whether used in oil and gas transportation systems or in offshore platforms and chemical plants, the corrosion resistance of ASTM A672 steel pipes makes them an ideal material for these challenging environments.

Optimized Alloy Composition: ASTM A672 steel pipes typically contain a balanced mix of alloying elements such as chromium, nickel, and molybdenum. These elements enhance the steel’s stability and oxidation resistance at high temperatures and in corrosive environments. For example, chromium improves the steel’s resistance to oxidation, preventing rusting in high-temperature air, while nickel and molybdenum increase its resistance to acidic and alkaline corrosion.

Strong Adaptability: Thanks to their excellent high-temperature and corrosion resistance, ASTM A672 steel pipes are widely used in environments with high levels of corrosion and temperature, such as offshore oil platforms, oil and gas transmission pipelines, and chemical reactors. Their versatility ensures that they meet the demanding conditions of various industrial applications, providing reliable performance and safety.

Applications of ASTM A672 Steel Pipes in Power Plants

ASTM A672 steel pipes, with their excellent high-temperature resistance, corrosion resistance, and strength, are widely used in various areas of power plants. Below are some typical examples of how ASTM A672 steel pipes are applied in power plants:

Cooling Water Piping Systems: Cooling systems are crucial for the operation of power plants, particularly in thermal and nuclear power plants. ASTM A672 steel pipes are widely used in cooling water pipelines due to their superior high-temperature and corrosion resistance. These pipes can operate efficiently under high-temperature and high-pressure conditions, ensuring the proper flow of cooling water to maintain the temperature of power generation equipment.

Steam Piping Systems: In thermal and nuclear power plants, steam pipelines play a critical role in energy generation. ASTM A672 steel pipes are commonly used for steam transmission due to their ability to withstand high-temperature and high-pressure environments. These pipes effectively carry high-pressure steam, ensuring the power plant’s operational efficiency and safety.

Heat Exchanger Pipelines: Heat exchangers in power plants are essential for transferring thermal energy and maintaining stable operating temperatures. ASTM A672 steel pipes are widely used in heat exchanger piping systems due to their excellent high-temperature and corrosion resistance. These pipes resist the corrosive substances that may be present in the cooling water and thermal media, extending the service life of the system and reducing maintenance costs.

Flue Gas Piping Systems: Power plants, particularly fossil fuel-based plants, require reliable systems for exhaust gas and smoke disposal. ASTM A672 steel pipes are commonly used in flue gas systems because of their stability at high temperatures and resistance to corrosion. These pipes can withstand the corrosive elements in flue gases, maintaining the integrity and efficiency of the piping system.

Fuel Gas Transport Pipelines: In natural gas power plants, fuel gas transportation requires high-strength, high-temperature pipes. ASTM A672 steel pipes, with their superior mechanical properties and corrosion resistance, are commonly used in fuel gas pipelines. These pipes ensure the safe and stable transportation of natural gas to fuel turbines for power generation.

Acid Wastewater Treatment Pipelines: Power plants generate acidic wastewater during coal combustion, which must be treated before discharge. ASTM A672 steel pipes are ideal for these wastewater treatment pipelines due to their corrosion resistance. These pipes can handle the corrosive acidic and alkaline wastewater, ensuring the efficient operation of wastewater treatment systems.

Quality Control and Specification Selection for ASTM A672 Steel Pipes

1. Quality Control

Raw Material Inspection: Ensure the steel meets standards through chemical composition and mechanical performance testing.

Process Control: Monitor temperature, pressure, and other parameters to avoid defects during manufacturing.

Welding Inspection: Use non-destructive testing to ensure weld quality.

Dimensional Checks: Ensure pipe dimensions (diameter, wall thickness) conform to standard requirements.

Pressure Testing: Ensure pipes can withstand operational pressures without leakage.

2. Choosing the Right Specifications

Pressure and Temperature: For high-pressure, high-temperature environments, choose stronger pipe specifications.

Corrosive Media: Select more corrosion-resistant pipes for corrosive environments.

Length and Bending: Choose pipes with the appropriate length and bending capabilities based on the design.

Budget and Standards: Balance the project budget with requirements, ensuring compliance with regional standards or certifications.

3. Installation and Maintenance Requirements for ASTM A672 Steel Pipes

1. Installation Requirements

Welding and Connections: Use appropriate welding materials and techniques during installation. After welding, conduct non-destructive testing to ensure quality.

Support and Fixing: Use suitable supports based on pipe size to ensure stability, especially in high-temperature and high-pressure environments.

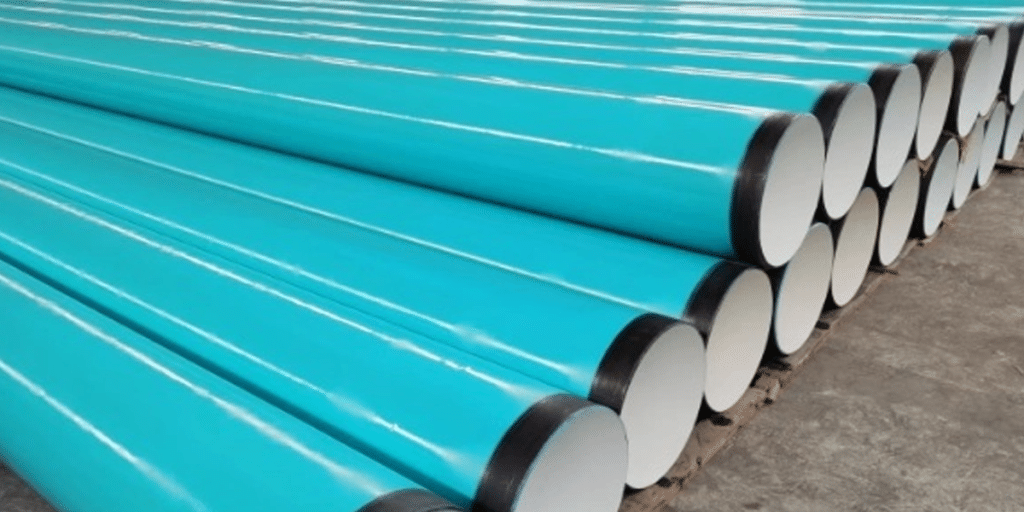

Corrosion Protection: Apply protective coatings to the pipes, especially when used in corrosive environments.

Installation Direction and Slope: Ensure the pipe direction is correct and set an appropriate slope to allow smooth fluid flow.

2. Maintenance Requirements

Regular Inspections: Check welding seams, pipe surfaces, and connections for cracks or corrosion, and address any issues promptly.

Pipe Cleaning: Clean the interior of the pipes regularly to prevent blockages or sediment buildup.

Corrosion Layer Maintenance: Check the integrity of protective coatings and repair any damage.

Pressure Testing: Perform regular pressure tests to ensure there are no leaks.

Replacement and Repair: Replace or repair severely damaged pipes to maintain system safety.

3. Safety Considerations

High-Temperature Safety: Workers should wear appropriate protective equipment when handling pipes in high-temperature environments.

Leak Detection: Install leak detection systems and perform regular safety checks.

Emergency Plan: Develop an emergency plan and conduct regular drills to handle potential pipe failures.

Future Development and Application Prospects of ASTM A672 Steel Pipes

1. Future Trends

Material and Technology Advancements: ASTM A672 steel pipes will see improvements in high-temperature and corrosion resistance, driven by technological advancements. Automation in manufacturing will also increase production efficiency and consistency.

Environmental Sustainability: Future production will focus on using eco-friendly materials and reducing carbon emissions. Longer-lasting, more corrosion-resistant pipes will reduce the environmental impact.

Demand for High-Performance Pipes: As industries like oil, gas, and energy require durable and reliable pipes, ASTM A672 steel pipes will be more in demand for extreme conditions like high pressure and high temperature.

2. Application Prospects

Oil and Gas: ASTM A672 pipes are widely used for transporting oil and gas, especially in high-pressure environments. The demand will continue to grow with the rise in global energy needs.

Power Plants: These pipes are essential in power plants, especially in steam systems that deal with high temperatures and pressures. As clean energy grows, their use will expand.

Chemical and Petrochemical Industries: Due to their corrosion resistance, ASTM A672 pipes will remain in high demand in the chemical industry, handling aggressive chemicals and high heat.

Water Treatment: With growing water treatment needs, ASTM A672 pipes will be increasingly used in water supply and wastewater systems due to their strength and corrosion resistance.

In conclusion, ASTM A672 steel pipes are set to remain a critical component in industries that require high-performance materials, especially in the oil and gas, power, chemical, and water treatment sectors. With advancements in technology, these pipes will continue to evolve, offering enhanced durability, better corrosion resistance, and greater environmental sustainability. As global industrial needs grow, the demand for ASTM A672 steel pipes will expand, ensuring their essential role in meeting the challenges of modern infrastructure and energy systems. As such, these pipes represent both a reliable and future-proof solution for various high-demand applications!