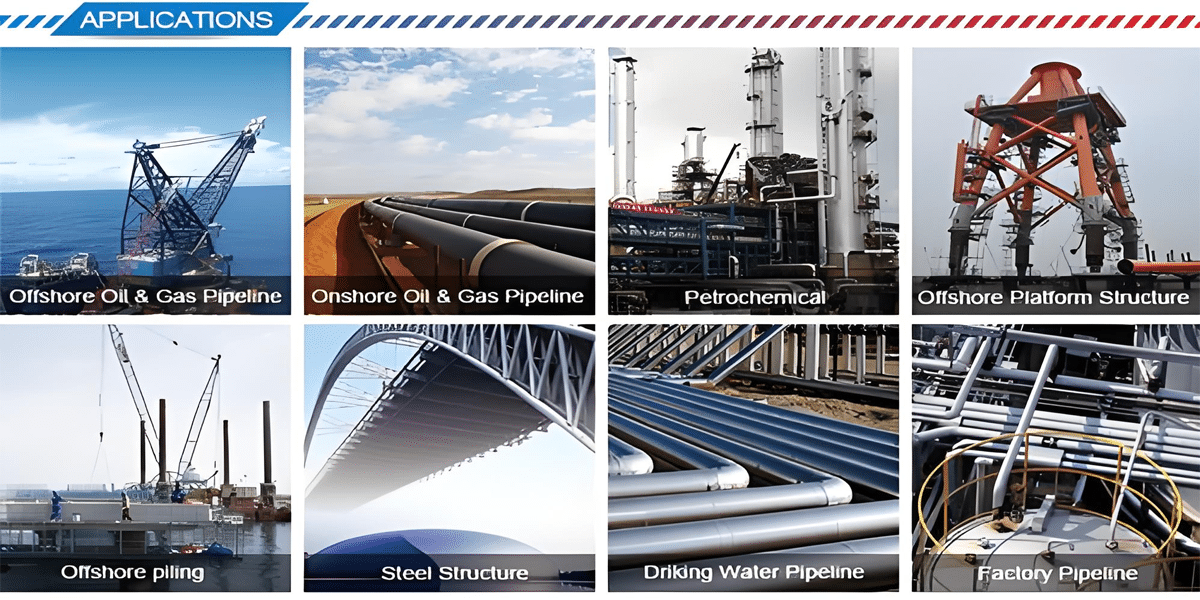

- 1. Core Advantages of API 5L Steel Pipes in Offshore Applications

- 2. Applications of API 5L Steel Pipes in Offshore Oil and Gas Platforms

- 3. Corrosion Resistance of API 5L Steel Pipes in Offshore Platforms

- 4. Selection and Standards of API 5L Steel Pipes in Offshore Oil and Gas Platforms

- 5. Future Trends of API 5L Steel Pipes in Offshore Oil and Gas Platforms

As global energy demand continues to rise, offshore oil and gas platforms have become pivotal hubs for energy production. However, the harsh marine environment—marked by corrosive seawater, high pressures, and extreme temperatures—poses significant challenges to pipeline systems. In such demanding conditions, what kind of material can ensure the safe and efficient transport of oil and gas? API 5L steel pipes, renowned for their exceptional strength, corrosion resistance, and reliability, have emerged as the cornerstone of offshore pipeline systems. But how exactly do these pipes meet the stringent requirements of the offshore environment? And what indispensable role do they play in the extraction, transportation, and storage of oil and gas? This article explores the critical applications of API 5L steel pipes in offshore platforms, uncovering how they enable the advancement of marine energy development!

Core Advantages of API 5L Steel Pipes in Offshore Applications

API 5L steel pipes are widely utilized in offshore platforms and marine oil and gas operations due to the following key advantages:

1. Exceptional Corrosion Resistance: In marine environments, pipeline systems are constantly exposed to high salinity and moisture, making corrosion a major concern. API 5L steel pipes are often manufactured with corrosion-resistant materials and can be further coated with internal and external anti-corrosion layers. This significantly extends their lifespan, particularly in oil pipelines and natural gas transportation systems.

2. High Strength and Superior Mechanical Properties: API 5L steel pipes offer high tensile and compressive strength, allowing them to withstand the immense pressure of deep-sea environments. This makes them ideal for transporting high-pressure oil and gas in offshore platforms.

3. Excellent Weldability: Offshore pipeline systems require extensive on-site welding. API 5L steel pipes are designed for excellent weldability, reducing welding complexity and ensuring efficient and reliable pipe connections.

4. Diverse Specifications for Versatile Applications: With various grades such as X42, X52, and X70, API 5L steel pipes provide a wide range of strength and size options to meet the diverse needs of offshore platforms, from deep-sea oil pipelines to high-pressure natural gas transport.

5. Outstanding Resistance to Temperature Variations: The deep-sea environment experiences significant temperature fluctuations. API 5L steel pipes maintain stable material performance under both low and high temperatures, preventing fatigue or cracking.

6. Globally Recognized Standards: Manufactured according to API (American Petroleum Institute) standards, API 5L steel pipes undergo rigorous production and testing processes. Their reliability and quality are trusted worldwide, particularly in critical offshore oil and gas production applications.

Applications of API 5L Steel Pipes in Offshore Oil and Gas Platforms

API 5L steel pipes play a critical role in offshore oil and gas platforms. As a core component of marine pipeline systems, they are widely used in oil and gas production, transportation, and storage. Their exceptional performance ensures the safety and efficiency of offshore energy development. Here are the primary applications of API 5L steel pipes in offshore oil and gas platforms:

1. Offshore Oil Pipelines: API 5L steel pipes are commonly used to transport crude oil from subsea wells to offshore platforms or from platforms to onshore terminals. Their high strength and corrosion resistance allow them to withstand the demands of high pressure and long-distance transportation while resisting corrosion caused by seawater and the marine environment.

2. Natural Gas Transportation Systems: Natural gas, as a vital clean energy source, requires transportation under high pressure from extraction sites to storage or processing facilities. API 5L steel pipes, particularly in high-strength grades such as X60 or X70, offer excellent pressure resistance, ensuring safe and stable natural gas transport.

3. High-Pressure Offshore Environments: In deep-sea oil and gas extraction, operating conditions involve extreme pressures. High-grade API 5L steel pipes, such as X80, are capable of withstanding these conditions, ensuring the safe operation of pipeline systems.

4. Integration with Corrosion-Resistant Coating Technologies: Given the high corrosiveness of the marine environment, API 5L steel pipes are often combined with advanced anti-corrosion coating technologies, such as epoxy resin coatings or polyethylene layers. These enhancements further improve their corrosion resistance, making them well-suited for long-term offshore operations.

Corrosion Resistance of API 5L Steel Pipes in Offshore Platforms

Offshore platforms, as key hubs for oil and gas development, are constantly exposed to the corrosive marine environment, characterized by high salinity, humidity, and seawater corrosion. This places extremely high demands on the corrosion resistance of pipeline materials. API 5L steel pipes, with their exceptional corrosion resistance properties, have become essential materials for oil and gas transportation systems on offshore platforms.

The Challenges of Seawater Corrosion

1. Resistance to Seawater Corrosion, Extending Service Life: In marine environments, pipelines are directly exposed to seawater, which has a high salt content, making them highly susceptible to electrochemical corrosion. API 5L steel pipes, manufactured with carefully selected materials and production processes, possess excellent corrosion resistance. Additionally, they can be coated with anti-corrosion layers such as epoxy resin or polyethylene coatings, significantly extending the lifespan of the pipelines.

2. Adapting to Humid and Salt-Spray Environments: Offshore platforms experience high humidity and intense salt spray, which can lead to rusting of traditional pipeline materials, affecting the safety and sealing of oil transportation. API 5L steel pipes’ corrosion-resistant properties effectively prevent rust-related thinning or leakage of the pipeline walls, ensuring efficient oil and gas production.

3. Handling High Pressure and Chemical Corrosion: During the transportation of crude oil and natural gas, API 5L steel pipes must withstand high pressure and resist corrosion caused by hydrogen sulfide, carbon dioxide, and other corrosive chemicals present in the oil and gas. The high-grade steel materials (such as X65 and X70) and advanced coating technologies ensure that API 5L steel pipes maintain stable performance in such extreme conditions.

4. Preventing Microbial Corrosion in Subsea Environments: Subsea pipelines are vulnerable to microbial-induced corrosion (MIC), where microorganisms form biofilms on the surface of the pipes, accelerating metal corrosion. The internal and external anti-corrosion coatings of API 5L steel pipes effectively prevent microbial attachment and corrosion, ensuring the long-term stability of subsea pipelines.

Anti-Corrosion Technologies for API 5L Steel Pipes

API 5L steel pipes are widely used in offshore platforms, oil and gas production, and transportation systems. Operating in highly corrosive environments, these pipes require advanced anti-corrosion technologies to enhance their durability and reliability. The primary methods include coating technologies and alloy design.

1. Coating Technologies

Coating technologies play a crucial role in protecting API 5L steel pipes by creating a barrier that isolates the pipe from corrosive agents, significantly improving its corrosion resistance.

1.1 Fusion Bonded Epoxy (FBE) Coating

FBE is a thermosetting epoxy powder coating applied to the heated surface of steel pipes. The coating forms a uniform, high-adherence protective layer upon fusion.

Features:

Excellent adhesion, preventing coating detachment.

Outstanding resistance to chemical corrosion, ideal for saline and sulfurous environments.

High-temperature resistance and superior mechanical durability.

Applications: Widely used in offshore oil pipelines and natural gas transportation, especially under high-pressure or deep-sea conditions.

1.2 Epoxy Resin Coating

Epoxy resin coatings consist of liquid or solid two-component systems applied through brushing, spraying, or dipping.

Features:

Exceptional anti-corrosion properties, resistant to salt spray, humidity, and chemicals.

Smooth surface reduces fluid transport resistance.

Can be combined with other coatings, such as polyethylene layers, for enhanced protection.

Applications: Suitable for oil and gas pipelines onshore and offshore, as well as internal piping systems on platforms.

1.3 Polyethylene (PE) or Polypropylene (PP) Multilayer Coatings

Three-layer (3LPE or 3LPP) coatings consist of a fusion-bonded epoxy base layer, an adhesive middle layer, and a polyethylene or polypropylene outer layer for multi-layered protection.

Features:

The epoxy base layer provides corrosion resistance, while the PE/PP outer layer enhances mechanical strength and abrasion resistance.

Ideal for long-term use in buried and subsea pipelines.

Applications: Commonly used in deep-sea pipelines and high-corrosion environments in oil and gas networks.

2. Alloy Design

In addition to external coatings, API 5L steel pipes use alloy design to enhance corrosion resistance from within the material itself.

2.1 Alloying Elements

Nickel (Ni): Improves corrosion resistance and toughness, suitable for low-temperature and highly corrosive environments.

Chromium (Cr): Enhances oxidation and chemical corrosion resistance, reducing risks of sulfide corrosion.

Molybdenum (Mo): Increases resistance to pitting corrosion in chloride-containing environments.

Copper (Cu): Adds resistance to salt spray and acidic corrosion.

2.2 Carbon Content Control:Reducing carbon content refines grain structure and improves weldability, minimizing intergranular corrosion.

2.3 Microalloying Technology: The addition of trace elements (e.g., vanadium, niobium, titanium) optimizes mechanical properties while enhancing corrosion resistance.

Case Study: Successful Application of API 5L in Offshore Oil and Gas Projects

API 5L steel pipes have become a reliable choice for offshore oil and gas projects due to their durability and corrosion resistance. Below is a case study that highlights their successful application in a major offshore oil platform project.

Project Overview: Offshore Oil Extraction Platform: An international oil company was tasked with setting up a large offshore oil extraction platform in the North Sea, one of the most challenging environments for oil and gas production due to its harsh weather conditions and saltwater exposure. The project required a robust pipeline system capable of withstanding extreme pressure, corrosion from seawater, and other environmental factors.

Selection and Standards of API 5L Steel Pipes in Offshore Oil and Gas Platforms

API 5L steel pipes are a preferred material for offshore oil and gas projects due to their excellent corrosion resistance, high strength, and reliability. The selection and standards of API 5L steel pipes ensure their superior performance in offshore environments, meeting the rigorous operational requirements of oil and gas platforms.

1. Selection Standards for API 5L Steel Pipes

When choosing the right API 5L steel pipes for offshore oil and gas platforms, several key factors must be considered:

1.1 Material Grades and Strength Requirements: API 5L steel pipes are classified into various grades, such as X42, X52, X60, X65, and X70. For offshore oil and gas platforms, where high pressure and deep-sea conditions are common, higher strength grades like X65 and X70 are typically chosen. These grades provide adequate tensile strength and resistance to high-pressure oil and gas transportation needs.

1.2 Corrosion Resistance: The corrosion issue is particularly severe in marine environments, especially with the presence of saltwater and sulfides. API 5L steel pipes often require corrosion protection treatments such as coating technologies (like FBE coatings) or alloy design. These treatments effectively prevent corrosion from saltwater, extending the lifespan of the pipeline.

1.3 Pipe Size and Wall Thickness: For offshore oil and gas platforms, the API 5L steel pipes need to be chosen based on the pressure requirements for oil and gas transportation. Larger diameter and thicker-walled pipes can withstand greater internal pressures and external mechanical impacts, especially in deep-sea oil extraction and long-distance transportation.

1.4 Weldability: Since offshore platform construction and maintenance often involve on-site welding, the weldability of the API 5L steel pipes is crucial. The pipes must exhibit good welding properties to ensure the strength and corrosion resistance of welded joints.

2. API 5L Steel Pipe Standards for Offshore Oil and Gas Platforms

The use of API 5L steel pipes on offshore oil and gas platforms must comply with certain industry standards to ensure safety, reliability, and long-term stability. Below are the commonly followed standards for API 5L steel pipes:

2.1 API 5L Standard: API 5L, developed by the American Petroleum Institute (API), sets the technical specifications for steel pipes used in oil and gas transportation. This standard defines material requirements, dimensions, tolerances, tensile strength, corrosion resistance, and other critical factors, ensuring the pipes can perform well in harsh offshore conditions.

2.2 ISO 3183 Standard: The ISO 3183 standard is closely aligned with API 5L and is widely used in international markets for oil and gas pipelines. It specifies the same material and performance requirements as API 5L but is recognized globally for offshore oil and gas transportation. Compliance with ISO 3183 is essential for meeting international standards and the needs of multinational corporations.

2.3 NACE MR0175 / ISO 15156 Standard: Offshore environments often contain hydrogen sulfide (H2S), which can cause severe corrosion. Therefore, API 5L steel pipes used on offshore platforms are typically required to comply with NACE MR0175 / ISO 15156 standards. These standards address the material’s resistance to hydrogen sulfide-induced corrosion, ensuring the pipes’ safety in hostile environments.

3. Considerations for Selecting API 5L Steel Pipes for Offshore Oil and Gas Platforms

When selecting API 5L steel pipes for offshore oil and gas platforms, the design and construction requirements of the platform must take into account the following factors:

Marine Environmental Challenges: Offshore environments are subject to saltwater, humidity, temperature fluctuations, UV radiation, and extreme weather conditions. API 5L steel pipes must be capable of withstanding these environmental challenges, ensuring long-term durability and performance.

Characteristics of the Transported Fluids: Offshore pipelines often transport oil, natural gas, liquefied natural gas (LNG), and other high-pressure, corrosive fluids. Therefore, API 5L steel pipes must have excellent sealing properties, pressure resistance, and chemical corrosion resistance.

Long Service Life and Low Maintenance Costs: Offshore platforms are often located far from land, making maintenance expensive and challenging. The selection of API 5L steel pipes with long-term durability helps reduce maintenance and replacement costs, ensuring a cost-effective operation.

Future Trends of API 5L Steel Pipes in Offshore Oil and Gas Platforms

As global oil and gas demand continues to rise, offshore oil and gas platforms are becoming increasingly crucial for energy production and storage. In this context, API 5L steel pipes, as the core component of offshore pipelines, will experience a series of technological innovations and development trends in response to the industry’s need for higher performance, longer service life, and lower costs. Here are the future trends of API 5L steel pipes in offshore oil and gas platforms:

1. Application of High and Ultra-High Strength API 5L Steel Pipes: As oil and gas extraction depths increase, offshore platforms face higher pressures and more complex environmental conditions. To address these challenges, API 5L steel pipes will trend toward the use of high-strength and ultra-high-strength materials. For example, grades such as X80 and X100 will be widely used in deep-sea and extreme conditions. These materials not only withstand higher internal pressures but also offer better impact resistance and fatigue durability.

2. Advancement of Advanced Corrosion Protection Technologies: Corrosive substances like saltwater and hydrogen sulfide in marine environments make corrosion resistance a critical factor. In the future, API 5L steel pipe corrosion protection technologies will become more advanced. In addition to traditional coatings like FBE (Fusion Bonded Epoxy), new coating technologies (such as dual-layer coatings, nano-coatings, etc.) will emerge as trends to provide longer-lasting and more effective corrosion protection. Additionally, with advances in material technology, the alloy design of API 5L steel pipes will be further optimized to enhance their corrosion resistance, ensuring long-term stable operation in offshore oil and gas platforms.

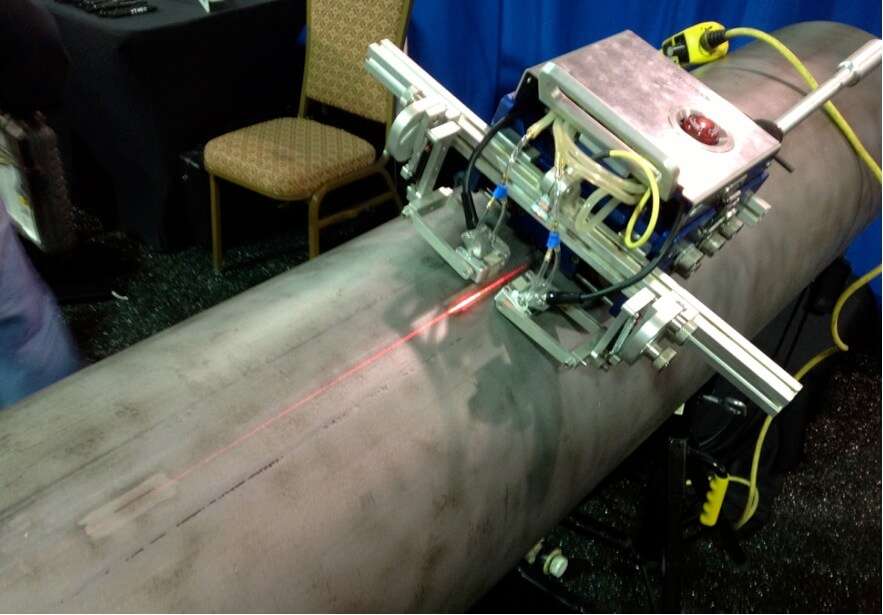

3. Integration of Smart and Automation Technologies: With the rapid development of the Internet of Things (IoT) and smart sensor technologies, API 5L steel pipes will gradually integrate intelligent systems. These smart systems can monitor the pipe’s operational conditions in real-time, such as pressure, temperature, and corrosion levels, providing data support for platform maintenance and management. Through data collected by sensors, operators will be able to identify potential issues in advance and take preventive measures to avoid pipeline damage or leakage.

4. Focus on Sustainability and Environmental Requirements: Environmental protection and sustainability demands are becoming stricter, and the offshore oil and gas industry must respond proactively. In the future, the production and use of API 5L steel pipes will place more emphasis on environmental responsibility. The manufacturing process will reduce harmful emissions, and material selection will consider recyclability and environmental impact. Furthermore, the lifecycle management of API 5L steel pipes will focus on extending their service life to reduce maintenance and replacement frequency, lowering operating costs.

In conclusion, API 5L steel pipes are crucial to the safe and efficient operation of offshore oil and gas platforms. As the industry faces increasingly harsh environmental conditions, these pipes, with their high strength, corrosion resistance, and advanced technologies, will continue to play a key role in offshore pipeline transportation. In the future, innovations in materials, corrosion protection, and smart monitoring systems will further enhance their performance, extend pipeline lifespans, and reduce operational costs. As offshore platforms expand in size, API 5L steel pipes will remain the core solution to address the challenges of complex marine environments. If you have any questions regarding the application of API 5L steel pipes in offshore operations, feel free to contact us, and we will provide professional services and customized solutions!