As global energy demands continue to rise, the development of infrastructure in the oil and gas sector has become more crucial than ever. At the heart of this industry lies the API 5L steel pipe, a material specifically engineered for the transportation of oil, gas, and other fluids.

Renowned for its exceptional strength, corrosion resistance, and durability, API 5L steel pipes have established themselves as a cornerstone for ensuring the safety and efficiency of energy transport! Currently, the API 5L steel pipe market is experiencing robust growth, with a wide range of grades and specifications catering to diverse engineering needs.

From subsea pipelines to onshore oil transport networks, from high-pressure applications in arctic regions to corrosion protection in tropical environments, API 5L steel pipes remain the top choice across various scenarios. But what makes these pipes so versatile and indispensable?

What technical advantages and market dynamics drive their demand? In this article, we’ll delve into the critical role of API 5L steel pipes in the oil and gas industry and explore the promising opportunities this market holds!

Definition and Features of API 5L Steel Pipes

Definition of API 5L Steel Pipes

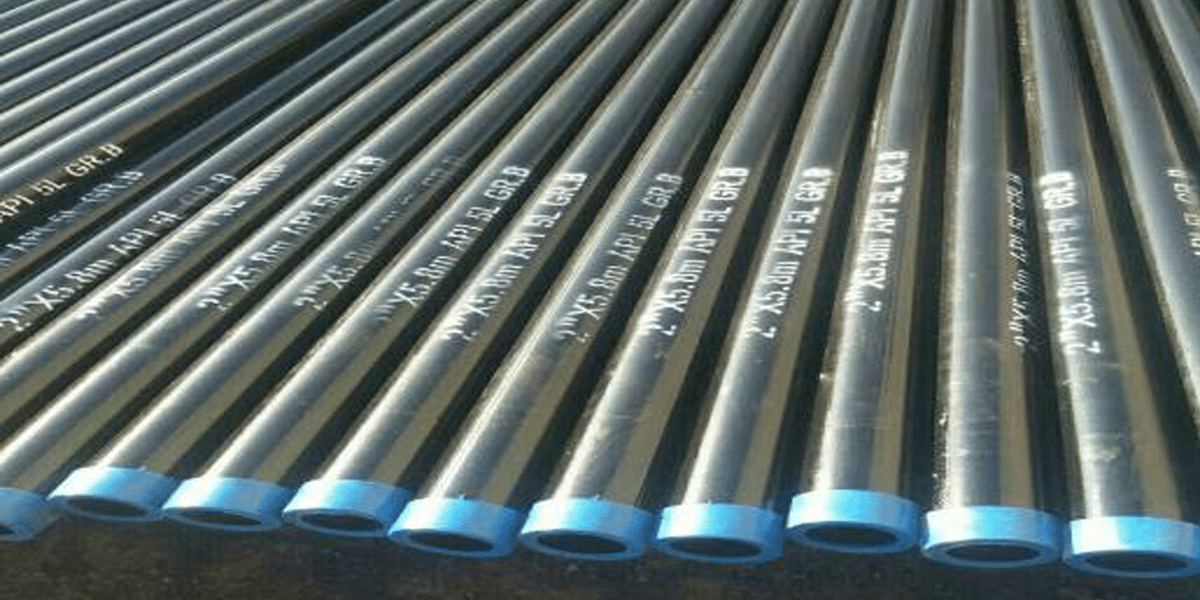

API 5L steel pipes are a type of pipe manufactured according to the standards set by the American Petroleum Institute (API). They are specifically designed for the transportation of oil, natural gas, and other fluids. Widely used in the global oil and gas industry, API 5L steel pipes are available in various grades, ranging from standard levels (Grade A and Grade B) to high-strength levels (such as X42, X52, X60, X70, and even X100), catering to diverse operational environments and technical requirements.

Features of API 5L Steel Pipes

High Strength and Pressure Resistance: API 5L steel pipes are capable of withstanding high-pressure environments, making them ideal for long-distance transportation of oil and gas through pipelines.

Excellent Corrosion Resistance: These pipes exhibit outstanding resistance to corrosive environments, such as acidic gases, saline water, and other aggressive substances, ensuring extended service life.

Diverse Specifications and Adaptability: vailable in both seamless and welded varieties, API 5L steel pipes can be customized in terms of diameter and wall thickness to meet the specific needs of different projects.

Superior Mechanical Properties: API 5L pipes offer high ductility and excellent toughness, ensuring reliable performance under extreme temperatures and challenging geological conditions.

Wide Range of Applications: These pipes are used in both onshore and offshore transportation systems, including cross-border oil pipelines, long-distance natural gas pipelines, and urban gas distribution networks.

Applications of API 5L Steel Pipes in Oil and Gas Transportation

With the growing global demand for energy, the safe and efficient transportation of oil and gas has become a top priority in the industry. As the preferred material for oil and gas pipelines, API 5L steel pipes not only meet the high-performance requirements of the industry but also demonstrate exceptional performance in a wide range of critical applications. Below, we explore the core demands of oil and gas pipelines and real-world application cases.

1. Core Demands of Oil and Gas Pipelines

High Strength and Pressure Resistance: Long-distance transportation of high-pressure oil and gas places extreme demands on pipeline mechanical properties. API 5L steel pipes have high yield strength and tensile strength, enabling them to withstand the high-pressure conditions encountered in oil and gas transportation. Higher-grade API 5L steel pipes (such as X70 and X80) are particularly suited for ultra-high-pressure systems, capable of withstanding the internal and external pressures generated during long-distance transportation, ensuring the safety of oil and gas transport.

Corrosion Resistance: Oil and gas transportation often involves sulfur-rich gases, saline water, and other corrosive media. API 5L steel pipes, through specific material composition and coating technologies, exhibit excellent corrosion resistance, ensuring the long-term stability of pipelines in complex environments.

Adaptability to Complex Terrain: API 5L steel pipes possess good toughness and ductility, making them suitable for complex terrains such as seismic zones, frozen ground, deserts, and seabeds, while maintaining structural integrity and sealing performance.

Cost-Effectiveness and Maintainability: API 5L steel pipes excel in material cost, transportation efficiency, and ease of maintenance, providing an economical and efficient solution for large-scale projects.

2. Real-World Application Cases of API 5L Steel Pipes

Cross-Border Long-Distance Oil Pipelines: For example, the China-Russia crude oil pipeline project used a large number of API 5L X70 steel pipes for long-distance transportation of crude oil over thousands of kilometers. The pipeline not only had to withstand extremely low temperatures but also ensure long-term transport efficiency, which was met by the high strength and low-temperature toughness of API 5L steel pipes.

Subsea Natural Gas Pipelines: In deep-sea gas transportation projects in the Gulf of Mexico, API 5L X65 steel pipes were successfully used in subsea natural gas pipelines thousands of meters below the surface. These pipelines had to cope with high pressure and corrosive seawater environments.

Urban Gas Distribution Networks: In urban natural gas distribution systems, API 5L steel pipes have become key materials for ensuring safe gas delivery due to their excellent sealing properties and adaptability. For example, API 5L B and X42 steel pipes have been used in large-scale gas networks in several major Chinese cities to meet medium- and low-pressure transportation needs.

Importance of Corrosion Resistance of API 5L Steel Pipes in Oil and Gas Pipelines

Corrosion is one of the primary challenges affecting the performance and safety of pipelines in long-distance oil and gas transportation. As pipelines are often exposed to harsh environmental conditions, corrosion can not only lead to leaks, ruptures, and other safety hazards but also reduce the lifespan of the pipeline, increasing maintenance costs. Therefore, the corrosion resistance of API 5L steel pipes plays a crucial role in ensuring the longevity and safety of oil and gas pipelines.

1. Challenges in Corrosive Environments

Acid Gases and Sulfur Compounds: During transportation, particularly in deep oil and gas fields, oil and gas are often accompanied by acid gases (such as H2S) and sulfur compounds. These chemicals accelerate pipeline corrosion, leading to hydrogen sulfide corrosion that damages the inner walls of the pipes.

Saltwater Corrosion in Marine Environments: Subsea oil and gas pipelines are often exposed to high-salinity seawater, which is a significant factor in the degradation of pipeline life. Chloride ions in seawater can accelerate corrosion, reducing the pipeline’s resistance to corrosion and potentially causing ruptures or leaks.

Soil Corrosion: For pipelines laid on land, soil corrosion is also a major concern. Chemicals, moisture, and electrical currents in the soil can cause electrochemical reactions on the pipeline’s surface, accelerating the corrosion process.

2. Corrosion Resistance Technologies of API 5L Steel Pipes

To address these challenges, API 5L steel pipes incorporate various advanced corrosion resistance technologies:

Alloyed Materials: By adding certain alloying elements, such as chromium, molybdenum, and nickel, the corrosion resistance of API 5L steel pipes is significantly enhanced. These alloying elements form a strong passive film that prevents external corrosive agents from reacting with the steel pipe surface, thus extending the pipeline’s service life.

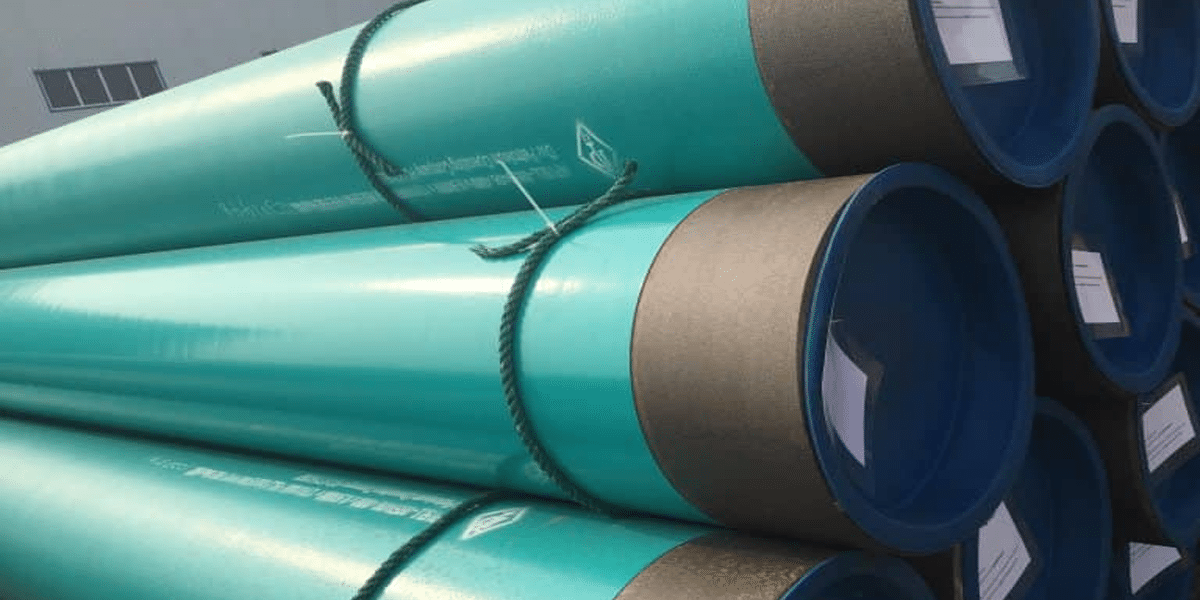

Coating Technologies: Protective coatings (such as epoxy coatings, polyethylene coatings, etc.) are applied to the exterior or interior walls of API 5L steel pipes to effectively isolate external corrosive agents and provide an additional protective layer. Coating technology is especially important for subsea and corrosive soil environments.

FBE Coating Technology: Fusion Bonded Epoxy (FBE) coating is a high-performance protective coating created through thermal curing. The process involves heating the steel pipe to a high temperature, applying the epoxy powder through electrostatic spraying, and then curing the coating to form a uniform protective layer. Widely used on the internal and external surfaces of API 5L steel pipes, FBE coating significantly improves the pipes’ stability and service life in challenging environments due to its excellent corrosion resistance, adhesion, and resistance to mechanical damage!

Cathodic Protection: Cathodic protection is a technique that interferes with electrochemical reactions through external current, often used to protect pipeline systems from corrosion. By implementing cathodic protection, API 5L steel pipes can significantly reduce the corrosion rate and prolong their lifespan.

3. Case Analysis

Subsea Natural Gas Pipeline Project: In a subsea natural gas pipeline project in the Gulf of Mexico, API 5L X65 steel pipes were equipped with advanced corrosion-resistant technologies, such as coating protection and alloyed materials, to resist corrosive chloride ions in seawater. These pipelines have successfully operated in harsh marine environments for years, demonstrating the excellent corrosion resistance of API 5L steel pipes.

Onshore Oil and Gas Pipeline Project: In China’s West-East Gas Pipeline Project, API 5L X70 steel pipes were widely used in the natural gas transportation system. These pipelines faced extreme weather conditions and soil corrosion. The incorporation of alloying materials and cathodic protection technology effectively reduced corrosion issues, ensuring the long-term safety and stability of the pipeline.

How to Select the Appropriate API 5L Steel Pipe Grade?

Choosing the right API 5L steel pipe grade is crucial to ensure the safety, reliability, and cost-effectiveness of pipeline systems in the oil and gas industry. The API 5L standard categorizes steel pipes into different grades, such as X42, X52, X65, and X70, based on material properties, manufacturing processes, and environmental considerations. Below, we provide a detailed guide on selecting the most suitable grade.

1. Based on the Nature of the Transported Medium

1.1 Liquid Transportation: For pipelines transporting crude oil or refined petroleum products, mid-to-low-grade pipes such as X42 or X52 are generally sufficient, as liquid transportation typically requires lower pressure.

1.2 Gas Transportation: Pipelines transporting natural gas or sour gas need to withstand higher pressures and corrosive environments. High-strength grades like X65 or X70 are better suited for long-distance, high-pressure gas transportation, especially in complex terrains.

2. Based on Pressure Requirements

The yield strength and tensile strength of API 5L steel pipes are key factors in determining their suitability for specific pressure conditions:

Low to Medium Pressure: Grades like X42 or X46 are suitable for applications such as urban gas pipelines.

High Pressure: Grades like X60 or X70 are ideal for regional or interregional gas pipelines operating under high pressure.

Ultra-High Pressure: For extreme applications like deep-sea oil and gas pipelines, higher-strength grades such as X80 are required.

3. Based on Geographical and Environmental Conditions

3.1 Corrosive Environments: In highly corrosive environments such as acidic soils or offshore locations, pipes with enhanced corrosion resistance are necessary:

Select PSL 2 grades with additional anti-corrosion treatments, such as FBE or 3LPE coatings.

For environments with high H₂S (hydrogen sulfide) content, opt for X65 or X70 pipes that pass HIC testing.

3.2 Extreme Temperature Conditions: In extreme cold or high-temperature areas, pipes with excellent impact toughness are essential. PSL 2 grades like X60 or X65 ensure resistance to brittle fracture under low temperatures.

4. Based on Construction Methods

4.1 Seamless Pipes (SMLS)

Best for high-pressure and high-temperature applications.

Commonly used in challenging geological conditions, such as seismic zones.

4.2 Welded Pipes (ERW, LSAW, SSAW)

ERW Pipes: Suitable for low- to medium-pressure transport with a good balance of cost and performance.

LSAW Pipes: Ideal for large-diameter, high-strength requirements, such as offshore pipelines.

SSAW Pipes: Versatile for long-distance transport with excellent adaptability.

5. Based on Standard Requirements

5.1 PSL 1 vs. PSL 2

PSL 1: General-purpose pipes with basic requirements, suitable for standard projects.

PSL 2: Pipes with stricter chemical composition and mechanical property standards, suited for high-demand applications.

PSL 2 grades like X65 or X70 are commonly used in cross-border gas pipeline projects.

5.2 Additional Testing Requirements

For corrosive or sour gas environments, specific tests are critical:

HIC (Hydrogen-Induced Cracking) Testing: To ensure resistance to hydrogen embrittlement.

SSC (Sulfide Stress Cracking) Testing: To verify resistance to cracking in sour environments.

International Standards and Certifications for API 5L Steel Pipes

API 5L steel pipes are essential components in the oil and gas industry, serving as conduits for transporting petroleum, natural gas, and other fluids. To ensure their reliability and safety, these pipes must adhere to specific international standards and certifications.

1. Standards and Certifications

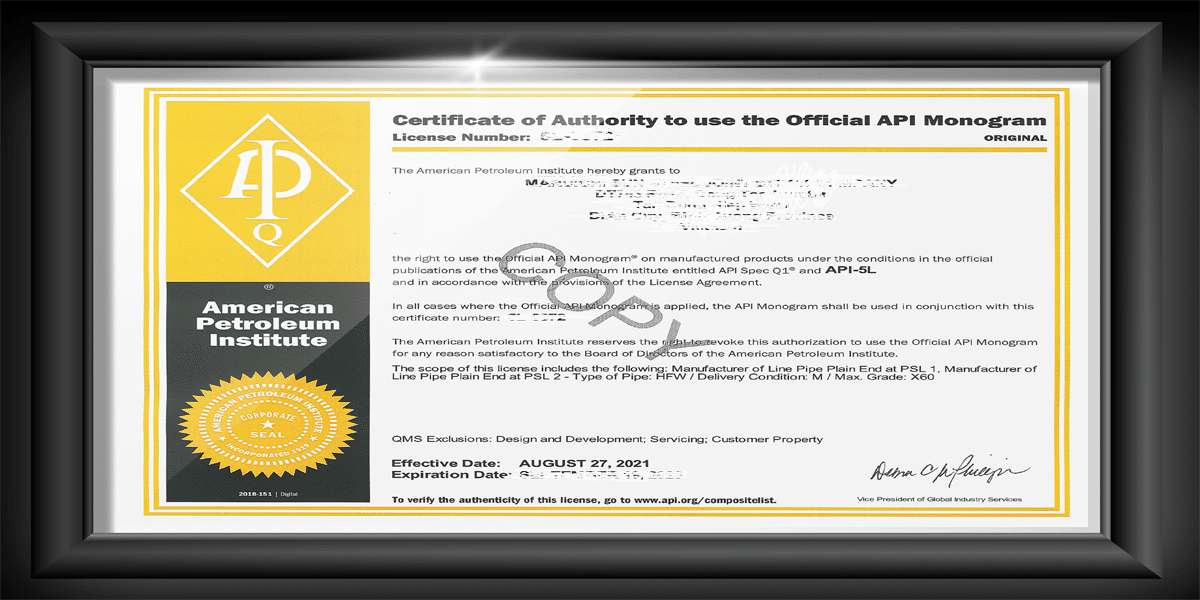

1. API 5L Standard: The American Petroleum Institute (API) Specification 5L outlines the requirements for the manufacture of two product specification levels (PSL1 and PSL2) of seamless and welded steel pipes. These specifications cover aspects such as chemical composition, mechanical properties, and testing methods to ensure the pipes’ suitability for pipeline transportation systems.

2. ISO 3183 Standard: ISO 3183 is an international standard that specifies requirements for the materials, manufacturing, testing, and documentation of steel pipes for pipeline transportation systems in the petroleum and natural gas industries. It aligns closely with the API 5L standard, facilitating global applicability and acceptance.

3. ASTM: ASTM International, formerly known as the American Society for Testing and Materials, is a globally recognized organization that develops and publishes voluntary consensus standards for a wide range of materials, products, systems, and services. While ASTM itself does not typically certify products or enforce compliance, it provides the standards that other organizations and laboratories use to test and certify products.

4. CE Certification: For steel pipes intended for the European market, obtaining CE (Conformité Européenne) certification is crucial. This certification indicates that the product complies with the European Union’s safety, health, and environmental protection requirements, allowing free movement within the European Economic Area.

2. Ensuring Compliance with Standards and Certifications

To guarantee that API 5L steel pipes meet the necessary standards and certifications, manufacturers should implement the following measures:

Quality Management Systems: Establish and maintain a robust quality management system, such as ISO 9001, to oversee all aspects of production, from raw material selection to final product inspection.

Rigorous Testing and Inspection: Conduct comprehensive testing, including mechanical tests (tensile strength, hardness), non-destructive testing (ultrasonic, radiographic), and hydrostatic testing, to verify the pipes’ integrity and performance.

Traceability: Maintain detailed records of the manufacturing process, including material certificates and test reports, to ensure full traceability of each pipe.

Third-Party Audits: Engage accredited third-party inspection agencies to perform audits and verify compliance with the relevant standards and certifications.

3. Quality Control and Inspection

Ensuring the quality and reliability of API 5L steel pipes is crucial for the safe transportation of oil and natural gas. Manufacturers implement comprehensive quality control measures and rigorous inspections throughout the production process to meet the stringent requirements of the API 5L specification.

1. Raw Material Inspection

Chemical Composition Analysis: Manufacturers conduct thorough chemical analyses to verify that the steel’s composition aligns with API 5L standards, ensuring the desired mechanical properties and performance.

Mechanical Property Testing: Tests are performed to assess properties such as yield strength, tensile strength, and impact toughness, confirming the material’s suitability for pipeline applications.

2. In-Process Quality Control

Dimensional Verification: Precise measurements of the pipe’s outer diameter, wall thickness, length, and straightness are taken to ensure adherence to specified tolerances.

Surface Inspection: Visual examinations, supplemented by techniques like liquid penetrant testing (PT) and magnetic particle testing (MT), are conducted to detect surface defects such as cracks or dents.

3. Final Product Testing

Hydrostatic Testing: Pipes are subjected to hydrostatic pressure tests to confirm their ability to withstand operational pressures without leaking or failing.

Non-Destructive Testing (NDT): Methods such as ultrasonic testing (UT) and radiographic testing (RT) are employed to identify internal and external defects without damaging the pipes.

4. Quality Management System

Documentation and Traceability: Each pipe is marked with unique identifiers, and detailed records of manufacturing processes and test results are maintained to ensure full traceability.

Compliance with Standards: Manufacturers adhere to quality management systems, such as ISO 9001, to maintain consistent production quality and meet international standards.

The Future Trends for API 5L Steel Pipes

1. Technological Innovations in Manufacturing: The integration of advanced manufacturing technologies, such as 3D printing and automated welding systems, is enhancing production efficiency and product quality. These innovations enable customized production to meet specific project requirements, thereby improving the overall performance and reliability of steel pipes.

2. Enhanced Strength and Corrosion Resistance: As exploration and production activities extend into deeper and more challenging environments, there is an increasing demand for steel pipes with higher strength and superior corrosion resistance. Grades such as API 5L X70 are widely used in long-distance transportation and high-pressure applications due to their excellent mechanical properties and resistance to corrosive substances.

3. Sustainability and Environmental Considerations: There is a growing emphasis on environmental sustainability, prompting manufacturers to adopt eco-friendly materials and processes. Utilizing low-carbon emission production methods and recyclable materials helps reduce the carbon footprint associated with steel pipe manufacturing.

4. Digitalization and Smart Management:The application of Internet of Things (IoT) technologies and big data analytics in steel pipe production and maintenance is becoming more prevalent. Real-time monitoring and data analysis facilitate predictive maintenance, optimize production processes, and enhance operational efficiency.

5. Global Market Integration and Collaboration: The oil and gas industry’s evolving landscape is fostering increased collaboration and consolidation among steel pipe manufacturers. For instance, Nippon Steel and Sumitomo Corporation have renewed a long-term contract with Equinor to supply seamless steel pipes for oil and gas development and carbon capture storage projects.

API 5L steel pipes hold a promising future in the oil and gas industry. With the continuous rise in global energy demand, the need for high-strength, corrosion-resistant, environmentally friendly, and intelligent steel pipes is steadily increasing. In the future, API 5L steel pipes will continue to innovate in materials, manufacturing technologies, and applications, driving the industry toward a more sustainable and smart direction. Through global collaborations and technological advancements, steel pipe manufacturers ensure that API 5L steel pipes can meet the challenges in diverse regions and environments, continuing to play a pivotal role in the transportation and distribution of oil and gas. Whether it’s for deep-sea pipelines, long-distance transportation, or emerging fields like carbon capture storage, API 5L steel pipes will remain a key material supporting the development of the energy industry!

LONGMA has been one of China’s leading steel pipe manufacturers since 2003, certified with API 5L, ISO9001, ISO14001, and FPC. Feel free to contact us for more information!