As global water scarcity and pollution continue to escalate, the water treatment industry has become increasingly vital in modern society. Water treatment pipelines, as a key part of infrastructure, ensure the safe supply of water resources. Among the many pipeline options, API 5L steel pipes stand out for their excellent corrosion resistance and strength, making them widely used in the water treatment sector, especially in the construction and maintenance of water supply pipelines. API 5L steel pipes not only effectively extend the lifespan of pipelines but also reduce maintenance costs, meeting the high standards required by modern water treatment systems.

As the water treatment industry evolves and environmental regulations become stricter, corrosion resistance has become a key factor in material selection. The application of API 5L steel pipes in water treatment pipelines enhances the overall performance of the system and drives technological advancements and market demand. In the following, this article will explore the specific applications and selection criteria of API 5L steel pipes in the water treatment industry!

Definition and Features of API 5L Steel Pipes

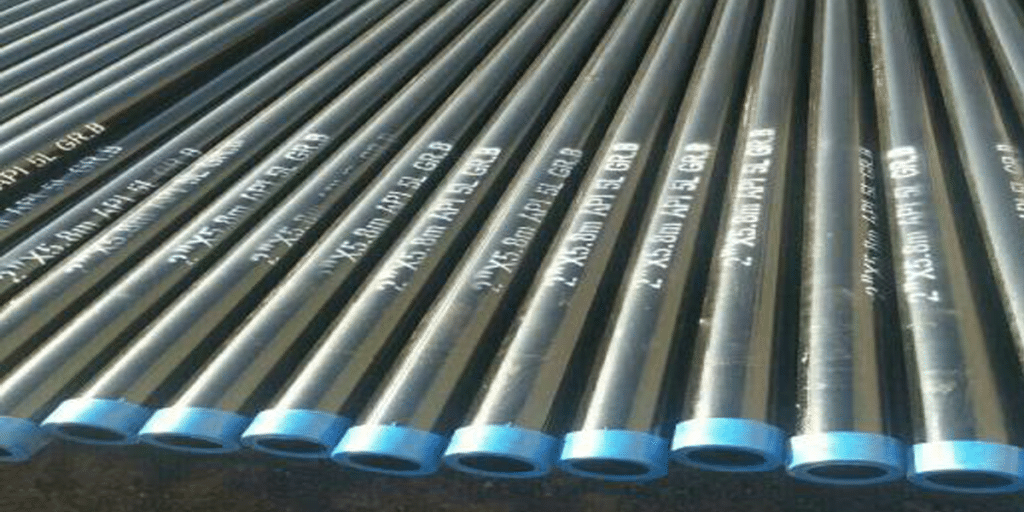

API 5L steel pipes are manufactured according to the standards set by the American Petroleum Institute (API) for the transportation of oil, natural gas, and other liquids. They are commonly used in pipelines for the oil and gas industry, offering high strength and corrosion resistance, ensuring the stable operation of pipelines in extreme environments. API 5L steel pipes come in various grades (such as B, X42, X52, X60, etc.), allowing them to meet the demands of different pressure and environmental conditions.

Key Advantages of API 5L Steel Pipes

Excellent Corrosion Resistance: API 5L steel pipes are designed with materials and anti-corrosion coatings that perform exceptionally well in harsh environments. Particularly in water treatment and water supply pipelines, they resist corrosion from chemicals, salts, and water, significantly extending the lifespan of the pipeline.

High Strength and High Pressure Capacity: The high strength of API 5L steel pipes allows them to withstand the high pressures of fluid transportation. They are suitable for pipelines transporting oil, natural gas, and water. Whether installed above or below ground, they ensure the stability of the pipeline system.

Adaptability to Extreme Environments: With excellent physical and chemical properties, API 5L steel pipes remain stable in extreme conditions, making them indispensable in industries requiring high temperature and corrosion resistance, such as water treatment.

Reduced Maintenance Costs: Due to their corrosion resistance, API 5L steel pipes minimize the need for frequent maintenance and replacement, effectively reducing the overall system maintenance costs. This is especially beneficial for water supply pipelines and water treatment systems.

Compliance with International Standards: API 5L steel pipes adhere to international standards, ensuring global recognition of their quality. This makes them a preferred pipeline material in various industries worldwide, particularly in water treatment and oil and gas transportation.

Applications of API 5L Steel Pipes in the Water Treatment Industry

API 5L steel pipes play an increasingly important role in the water treatment industry due to their excellent corrosion resistance, strength, and ability to withstand extreme environments. Below are some of the key application scenarios of API 5L steel pipes in the water treatment sector:

Water Supply Pipelines: API 5L steel pipes are ideal for the construction of water supply pipelines. Their corrosion-resistant properties enable them to work reliably in various water quality environments, preventing pipeline damage caused by chemicals in the water. Particularly in underground pipelines and long-distance water supply systems, API 5L steel pipes are able to withstand high water pressures and external forces, ensuring safe and reliable water transport.

Sewage Treatment Pipelines: In sewage treatment plants, API 5L steel pipes are used for transporting sewage and wastewater. The corrosive elements in sewage demand high standards for pipeline materials, and API 5L steel pipes, with their exceptional corrosion resistance and chemical resistance, provide long-term stability in transporting treated water and wastewater, reducing maintenance and replacement costs.

Desalination Systems: Desalination is an essential method for addressing water scarcity. Given the high salt content in seawater, the corrosion resistance of API 5L steel pipes is critical in desalination systems. Their resistance to salt corrosion makes them highly effective in seawater treatment processes, ensuring the long-term stable operation of desalination water pipelines.

Reclaimed Water Pipelines: In the field of water reuse, API 5L steel pipes are widely used for transporting reclaimed water. As environmental protection standards rise, the use of reclaimed water has become more widespread, and API 5L steel pipes are increasingly employed in reclaimed water systems. Their corrosion resistance and high strength ensure the long service life of pipelines, enhancing the efficiency of water treatment systems while reducing maintenance costs.

Industrial Water Treatment Pipelines: In large industrial facilities, API 5L steel pipes are used for handling and transporting industrial wastewater. Due to the harmful components in industrial wastewater, the corrosion resistance and high-temperature tolerance of API 5L steel pipes make them an ideal choice for industrial water treatment systems.

The Key Role of Corrosion Resistance in Water Treatment Pipelines

Corrosion resistance is one of the most critical factors when selecting pipeline materials for water treatment systems. Water often contains various corrosive substances such as chemicals, salts, and other pollutants, which can lead to pipeline corrosion and wear, shortening the pipeline’s lifespan, increasing maintenance costs, and even affecting water quality safety. Therefore, choosing materials with excellent corrosion resistance is essential to ensure the long-term stable operation of water treatment systems.

Challenges of Corrosion Issues: Corrosion in water treatment pipelines primarily stems from corrosive components in the water, such as chlorides, sulfides, and acidic substances. Over time, these elements gradually damage the surface of pipelines, leading to cracks, holes, and even ruptures. Corrosion not only affects water flow but may also cause pipeline leaks, which can seriously compromise the safety of the entire water supply system. Additionally, byproducts of corrosion can contaminate the water, affecting its cleanliness. Preventing corrosion is therefore a critical task for ensuring the stable operation of water treatment systems.

Corrosion Resistance Technology of API 5L Steel Pipes

API 5L steel pipes are widely recognized in the water treatment industry due to their excellent corrosion resistance. Their corrosion-resistant technology is reflected in several key aspects:

High Alloy Composition: API 5L steel pipes typically contain high-quality alloy elements such as chromium and nickel, which enhance the corrosion resistance of the pipes, enabling them to withstand various corrosive substances found in different water environments.

Anti-corrosion Coatings: To further improve corrosion resistance, API 5L steel pipes are often coated with anti-corrosion layers or subjected to special surface treatments, such as hot-dip galvanizing or coating processes. These measures effectively prevent direct contact between the pipe and corrosive elements in the water, extending the lifespan of the pipeline.

Chemical Corrosion Resistance: The chemical corrosion resistance of API 5L steel pipes makes them particularly suitable for harsh environments such as wastewater and seawater, which contain corrosive substances. API 5L steel pipes can effectively resist corrosion even in acidic or alkaline conditions.

Case Studies

Application in Water Supply Pipelines: In some urban water supply systems, pipelines exposed to high-salinity environments often face corrosion issues. To improve the pipeline’s durability and ensure water quality, engineers selected API 5L steel pipes. Due to their excellent corrosion resistance, API 5L steel pipes can work reliably in high-salinity water environments for long periods, avoiding the corrosion problems associated with traditional pipe materials. This significantly extends the lifespan of the water supply pipelines and reduces maintenance and replacement frequencies.

Application in Desalination Systems: In desalination systems, seawater’s high salt content is the primary source of corrosion. After using API 5L steel pipes, pipelines not only resist salt corrosion but also endure high-pressure environments during long-distance fluid transportation, ensuring stable supply of desalinated water.

API 5L Steel Pipe Standards and Selection

1. API 5L Steel Pipe Standards

API 5L steel pipes are widely used in industries such as oil and gas, water treatment, and other pipeline transportation systems. These pipes are designed and manufactured according to stringent international standards, ensuring their quality and safety. Some of the key standards that govern API 5L steel pipes include ISO and ASTM, which provide detailed specifications on design, production, testing, and performance, ensuring that these pipes meet the required quality and safety criteria.

1.1. Overview of API 5L Steel Pipe Standards

API 5L is a standard developed by the American Petroleum Institute (API), primarily for pipelines used in the transportation of petroleum, natural gas, and other fluids. This standard sets out the specifications for material, size, and performance, which are essential to ensure the reliability and safety of API 5L steel pipes in various applications.

Material Grades: API 5L steel pipes are classified into different grades based on their strength and resistance to corrosion, including Grade B, X42, X52, and others. The grades are selected based on the pressure and environmental conditions of the pipeline.

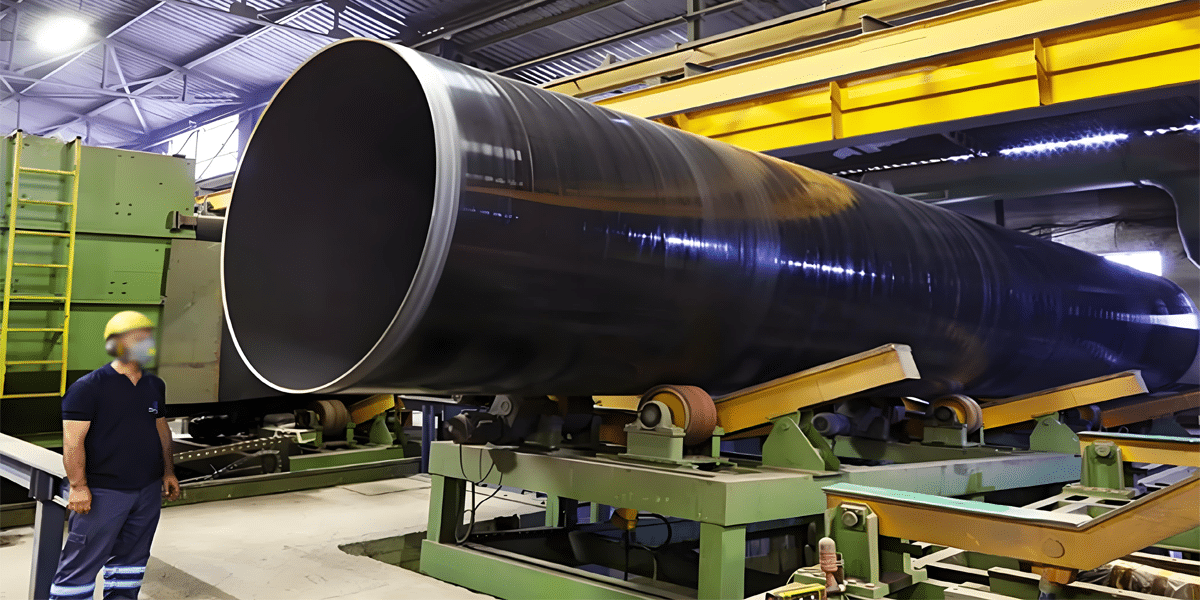

Pipe Dimensions and Wall Thickness: The standard provides specific requirements for the dimensions and wall thickness of the pipes, ensuring that they can withstand both internal and external pressures.

Testing and Inspection: API 5L steel pipes undergo rigorous quality testing, including physical properties, chemical composition, and surface quality, to ensure they meet the standards required for safe and efficient use.

1.2. Standards

1. ISO Standards: The International Organization for Standardization (ISO) has published several standards related to steel pipes, which also apply to API 5L steel pipes. ISO standards focus on creating uniform global requirements for steel pipe manufacturing, including pipe dimensions, material properties, and production processes. These standards ensure that API 5L steel pipes are consistent and applicable worldwide.

2. ASTM Standards: The American Society for Testing and Materials (ASTM) is another significant organization that sets standards for steel pipes. ASTM standards are crucial for manufacturing processes and testing methods related to API 5L steel pipes.

1.3. How Industry Standards Ensure the Quality and Safety of Pipes?

The industry standards for API 5L steel pipes play a vital role in ensuring the quality and safety of the pipes. Here’s how these standards contribute to their reliability:

Consistency and Reliability: By adhering to global standards like API, ISO, and ASTM, steel pipe manufacturers must follow the same protocols, ensuring consistency in quality. This consistency is essential for API 5L pipes to function safely and effectively in pipelines worldwide.

Safety: The API 5L standard requires that pipes undergo comprehensive testing for pressure resistance, corrosion, and strength. These tests ensure that the pipes won’t fail under pressure or environmental conditions, reducing the risk of leaks, ruptures, or other safety hazards.

Adaptability to Various Environments: Different environmental conditions, such as extreme temperatures or corrosive water, impose unique requirements on pipelines. API 5L steel pipes are available in various grades and can be treated with anti-corrosion coatings to ensure they maintain performance in demanding environments, such as desalination plants or chemical processing systems.

Quality Control and Certification: Industry standards set forth clear guidelines for quality control during manufacturing. Manufacturers must provide documentation to prove that the pipes meet the required standards, ensuring traceability and verification of quality for end-users.

2. How to Choose the Right API 5L Steel Pipe Grade for Water Treatment Pipelines

Selecting the appropriate API 5L steel pipe grade depends on several critical factors:

Water Quality and Corrosiveness: Evaluate the presence of corrosive substances in the water, such as chlorides and sulfides. For environments with high corrosiveness, pipes with higher corrosion resistance, such as API 5L X60 or X70, are recommended.

Pressure Requirements: For pipelines subject to high water pressure, such as those used in deepwater environments or high-pressure wastewater systems, higher-grade steel pipes (e.g., X60 and above) are necessary to ensure safety and reliability.

Operating Environment: In extreme environments like high-temperature or seawater settings, opt for grades with superior strength and corrosion resistance. For example, desalination systems often use API 5L X70 due to the high salt content and pressure demands.

3. Ensuring Compliance with Water Treatment Industry Standards

To ensure that API 5L steel pipes meet the standards and requirements of the water treatment industry, consider the following steps:

Adherence to International Standards: Verify that the selected API 5L steel pipes comply with API 5L specifications and have passed relevant quality inspections. Tests such as pressure, tensile strength, and corrosion resistance should confirm the material’s suitability for water treatment applications.

Certified Suppliers: Work with experienced and certified API 5L steel pipe suppliers who can provide the required documentation and quality assurance.

Ensure the supplier’s products meet industry-specific standards for water treatment pipelines.

Appropriate Anti-Corrosion Treatment: Given the exposure to corrosive substances in water treatment processes, ensure the pipes are treated with protective coatings, such as galvanization or specialized anti-corrosion layers. These measures can significantly enhance durability and extend the pipeline’s service life.

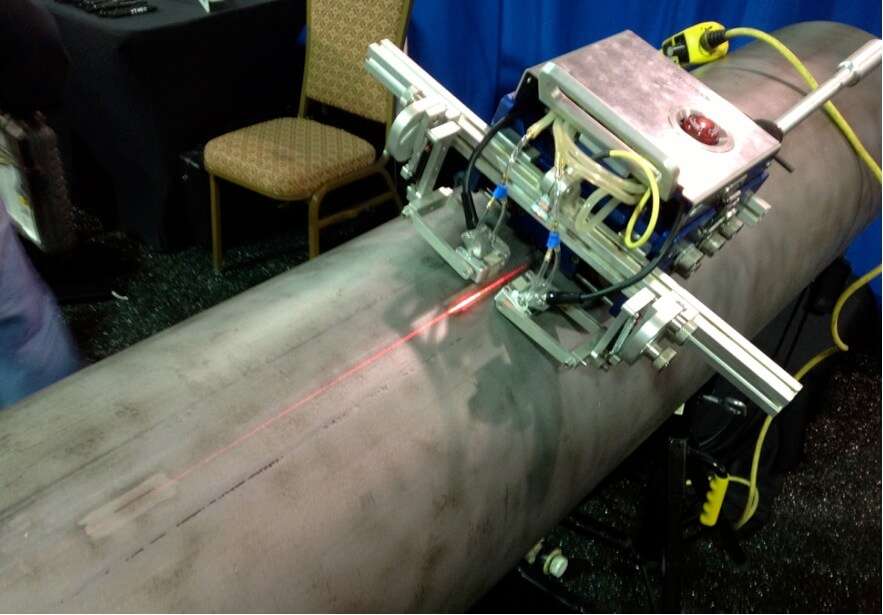

Regular Inspection and Maintenance: Even with high-quality materials, regular inspection and maintenance are essential. Routine checks on corrosion levels, pressure capacity, and overall condition can help identify potential issues early and maintain system integrity.

Future Trends of API 5L Steel Pipes in the Water Treatment Industry

As the global demand for clean water continues to rise and environmental regulations become more stringent, the water treatment industry is evolving rapidly. API 5L steel pipes, known for their excellent strength and corrosion resistance, are playing an increasingly important role in the modernization and expansion of water treatment infrastructure. The future of API 5L steel pipes in this industry is shaped by several key trends:

1. Increasing Demand for Durable and Corrosion-Resistant Materials: One of the most critical factors in water treatment systems is the longevity and durability of the materials used in piping. API 5L steel pipes, with their superior corrosion resistance, are well-suited to handle harsh water treatment environments. As more regions face issues like water contamination and the need for advanced water filtration systems, the demand for corrosion-resistant materials like API 5L steel pipes will continue to grow. These pipes can withstand exposure to acidic or alkaline water conditions, ensuring the longevity of water supply networks and reducing maintenance costs.

2. Integration of Sustainable and Eco-Friendly Technologies: As sustainability becomes a priority in industries worldwide, water treatment plants are increasingly focusing on eco-friendly solutions. API 5L steel pipes are being incorporated into systems that emphasize energy efficiency and environmental conservation. With their ability to handle high-pressure systems efficiently, these pipes will be crucial in the implementation of energy-saving technologies such as pump optimization and leak detection systems. Additionally, the demand for recycled or sustainably produced API 5L steel pipes may increase as companies and governments aim to meet sustainability goals.

3. Advancements in Anti-Corrosion Coatings: While API 5L steel pipes already offer excellent corrosion resistance, the future may see even more advanced anti-corrosion technologies being applied. The continuous development of protective coatings, such as epoxy and fusion-bonded coatings, will enhance the lifespan of API 5L steel pipes in water treatment systems. These coatings provide an additional layer of protection against aggressive substances, like chlorine, found in water treatment plants, helping to extend the life of the infrastructure and minimize the need for frequent replacements.

4. Smart Water Management and IoT Integration: The future of water treatment involves the integration of smart technologies that enable real-time monitoring and optimization of water distribution networks. API 5L steel pipes, integrated with sensors and connected to the Internet of Things (IoT), will play a pivotal role in the development of smart water systems. These intelligent systems can detect leaks, measure flow rates, and optimize water usage, all of which contribute to more efficient water treatment processes. API 5L steel pipes will likely be at the forefront of these innovations, ensuring that the infrastructure is robust enough to support the increasing complexity of water management.

5. Expansion in Emerging Markets: Emerging economies, particularly in Asia and Africa, are investing heavily in water infrastructure to meet the needs of growing urban populations. API 5L steel pipes are well-positioned to meet the needs of these markets due to their affordability, strength, and ease of installation. As these regions build or upgrade their water treatment systems, the demand for API 5L steel pipes will surge, particularly for water supply pipelines that require durable materials capable of withstanding the rigors of diverse and sometimes extreme environments.

In conclusion, API 5L steel pipes have proven to be an invaluable material in the water treatment industry. Their exceptional strength, corrosion resistance, and ability to withstand harsh environments make them a reliable choice for water supply pipelines and other critical infrastructure. As the demand for clean water grows and environmental challenges continue to evolve, the role of API 5L steel pipes in modernizing water treatment systems becomes even more crucial. Looking ahead, the future of API 5L steel pipes in water treatment is promising, with advancements in corrosion protection, smart water management technologies, and sustainable practices further enhancing their value. With the growing emphasis on efficient, durable, and eco-friendly materials, API 5L steel pipes will remain central to ensuring the longevity and reliability of water treatment infrastructure worldwide. Their continued application will be pivotal in meeting the global demand for safe and clean water, ultimately contributing to a more sustainable and secure future for communities everywhere!