- 1. AS NZS 1163 C250 C350 hollow sections overview

- 2. Structural applications

- 3. Mechanical and industrial applications

- 4. Infrastructure and construction projects

- 5. Comparison with other structural materials

- 6. Quality control and compliance

- 7. Environmental and safety considerations

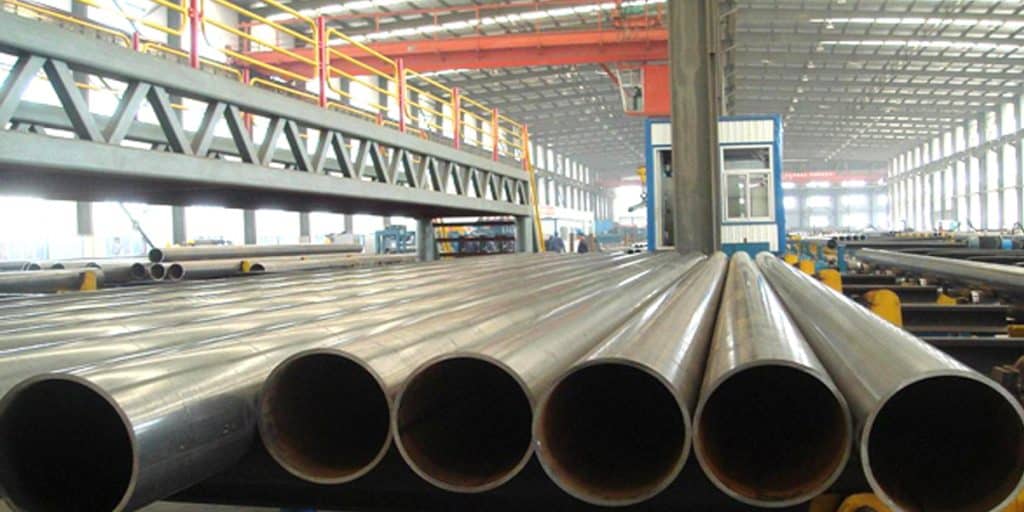

- 8. This is AS NZS 1163 C250 C350 hollow sections

What are the applications of AS NZS 1163 C250 C350 hollow sections?

AS NZS 1163 C250 C350 hollow sections are structural steel materials that fall under the category of cold-formed welded structural steel hollow sections. These materials are specified by Australian standards and are popular in the construction and engineering industries for their superior strength, durability and versatility. Exploring the various applications of AS 1163 C250 and C350 hollow sections is essential to understanding their importance and potential for a variety of structural and mechanical uses.

The aim of this paper is to provide a comprehensive overview of the applications of AS 1163 C250 and C350 hollow sections, emphasizing their importance in construction, infrastructure and engineering projects. By examining their structural, mechanical and industrial applications, as well as environmental and safety considerations, an understanding can be gained of the versatility and reliability of these materials in supporting modern construction and engineering practices.

AS NZS 1163 C250 C350 hollow sections overview

AS 1163 C250 and C350 are the Australian standard specifications for cold-formed welded structural steel hollow sections. AS 1163 C250 and C350 hollow sections are known for their high strength, durability and suitability for a wide range of applications in construction and engineering projects.

The production process involves cold bending steel plates or coils into hollow tubes and then welding them together. This process produces hollow sections with uniform dimensions, excellent mechanical properties and consistent quality in a wide range of applications AS 1163 C250 and C350 hollow sections are available in a wide range of sizes and wall thicknesses to meet a variety of structural and mechanical requirements

Structural applications

One of the main areas of application for AS 1163 C250 and C350 hollow sections is structural applications in building construction, infrastructure projects and civil engineering. These materials have a high strength-to-weight ratio and resistance to bending and deformation and are therefore widely used as load-bearing structures, columns, beams, trusses and other structural members.

AS 1163 C250 and C350 hollow sections provide cost-effective solutions for structural framing and bracing systems in residential, commercial and industrial buildings as well as bridges, towers and other infrastructure projects. Their hollow nature facilitates transportation and installation, while their strength ensures safety and durability under a variety of loading conditions.

Mechanical and industrial applications

In addition to structural applications, AS 1163 C250 and C350 hollow sections are used in a wide range of mechanical and industrial applications, including machinery, equipment and material handling systems. Their high strength, stiffness and light weight make them ideal for use in conveyor systems, storage racks, frames and other mechanical components that require reliable performance and ease of installation.

In industrial environments, AS 1163 C250 C350 hollow profiles can be used to build material handling equipment, manufacturing machinery and processing lines. Its versatility allows for customization and adaptation to meet specific requirements, helping to increase efficiency and productivity in a variety of industries.

Infrastructure and construction projects

AS 1163 C250 and C350 hollow sections play an important role in infrastructure and construction projects such as bridges, highways and transit facilities. Their strength and durability make them suitable for supporting structural elements in these critical projects, ensuring safety and longevity in high-stress environments.

In addition, AS 1163 C250 and C350 hollow sections can be used to build sidewalks, railings, sign structures and architectural features. Lightweight and easy to install, they are ideal for enhancing the functionality and aesthetics of public spaces and cityscapes.

Comparison with other structural materials

While AS 1163 C250 C350 hollow profiles offer many benefits, it is important to compare their characteristics and performance with other structural materials commonly used in similar applications.

Compared to traditional materials such as wood or concrete, AS 1163 C250 and C350 hollow sections offer greater strength, durability and resistance to the elements.

However, alternative materials such as aluminum or composites may offer advantages in specific applications, such as better corrosion resistance or a higher strength-to-weight ratio. The selection of AS 1163 C250 and C350 hollow sections or other materials depends on factors such as structural requirements, environmental conditions and cost-effectiveness.

Quality control and compliance

To ensure the reliability and safety of structures and components made from AS 1163 C250 and C350 hollow sections, stringent quality control measures and compliance standards are implemented throughout production and application. Rigorous testing protocols and certification requirements have been established by the Australian Iron and Steel Institute and other regulatory bodies to ensure the consistent quality and performance of these materials.

Compliance with industry regulations such as the Australian Standards and Building Codes is essential to maintain the structural integrity and safety of buildings using AS 1163 C250 and C350 hollow sections Regular inspections, testing and monitoring are carried out to identify and resolve any potential issues or deviations from established standards

Environmental and safety considerations

Environmental and safety considerations must be taken into account when using AS 1163 C250 C350 hollow sections in construction and engineering projects to reduce risk and promote sustainability.

Implement safety protocols to ensure safe handling, installation and operation of AS 1163 C250 and C350 hollow sections. Appropriate personal protective equipment, safe lifting methods and adherence to site safety regulations are essential to prevent accidents and injuries during construction and maintenance activities.

In addition, efforts are being made to explore sustainable practices and innovations in the use of AS 1163 C250 and C350 hollow sections, such as recycling and reuse of materials, minimization of waste and adoption of energy-efficient production processes.

This is AS NZS 1163 C250 C350 hollow sections

AS NZS 1163 C250 C350 hollow sections have proven to be versatile and reliable materials in the construction, engineering and industrial sectors. Their structural integrity, durability and adaptability make them suitable for a wide range of applications from load-bearing structures and infrastructure projects to machinery and industrial equipment.

The versatility of AS NZS 1163 C250 C350 hollow sections lies in their ability to support a wide range of structural and mechanical requirements, while providing cost-effective solutions compared to other materials.

As the demand for sustainable and innovative building practices continues to grow, the role of AS NZS 1163 C250 C350 hollow sections/steel pipes in driving progress and contributing to modern engineering projects becomes increasingly important.

LONGMA is one of China leading AS/NZS 1163 steel hollow section manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC. Contact by info@ilongma.com to get more information about the applications of AS/NZS 1163: 2016 hollow sections?

References:

- Australian Steel Institute. (2021). AS 1163 Structural Steel Hollow Sections.

- Standards Australia. (2016). AS/NZS 1163:2016 Cold-formed structural steel hollow sections.

- NCCBP. (2019). National Structural Steelwork Specification for Building Construction (6th Edition).

- Steel Construction Institute. (2017). Structural Design of Stainless Steel Hollow Section Members.

- Tata Steel. (2021). Structural Hollow Sections – Applications and Benefits.

- Choo, Y.S., Liang, J.X., & Wilkinson, T. (2014). Structural Behavior of Steel Hollow Sections in Construction.

- American Institute of Steel Construction. (2021). Design Guide for Round Hollow Structural Sections.

- European Convention for Constructional Steelwork. (2008). Design Manual for Structural Hollow Section Columns.