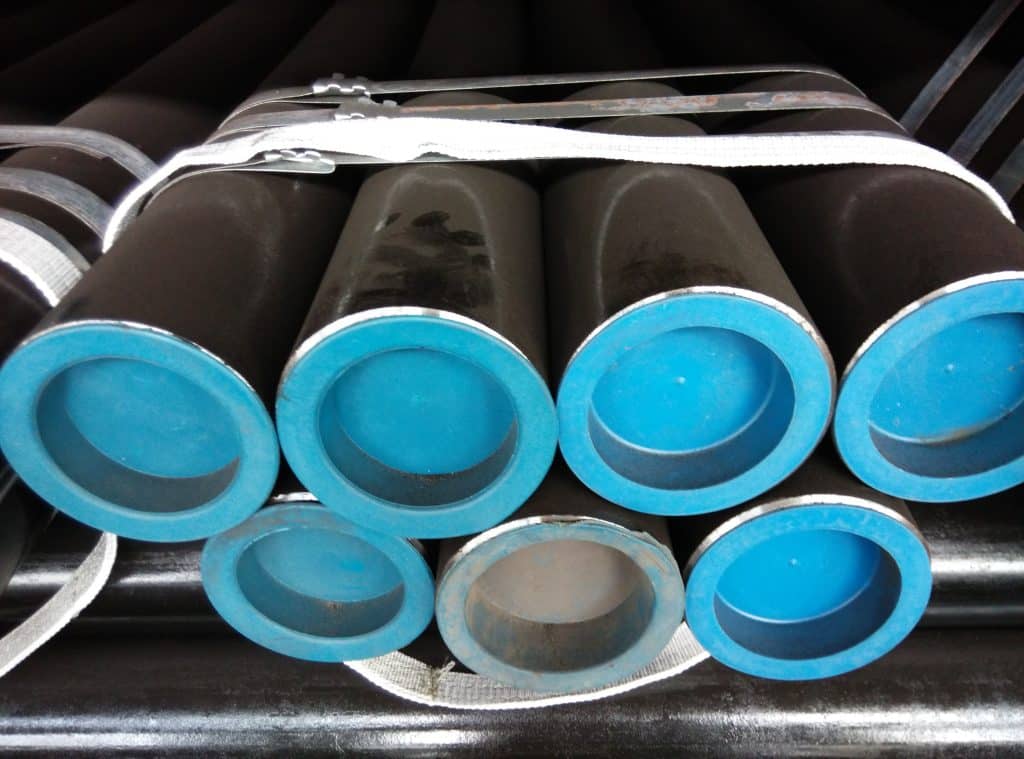

Your ASTM A53 ERW steel pipes manufacturer in China

Longma produces and stocks a full range of ASTM/ASME A53/SA53 B seamless and welded steel pipe which is a general, all-purpose pipe used in generator plants, refineries, compressor stations, natural gas transmission, and steam conduction. It is acceptable for welding, flanging, and bending.

- Grades: B

- Outer Diameter: 1/8″ NPS to 26″

- Thickness: SCH 10. SCH 20, SCH 40, STD, SCH 80, SCH XS, to SCH XXS

- Manufacturing Types: Seamless, ERW (Electric resistance welded)

- Length Range: SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized

- Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, FBE, HDG(Hot Dipped Galvanized)

Our Certifications

Our ASTM A53 ERW Steel Pipes Product List

Longma is one of the leading ASTM A53 GR.B ERW/Seamless Steel Pipe manufacturer since 2003.

ASTM A53 Grade B Pipe

ASTM A53 Schedule 40 ERW Pipe

ASTM A53 B Steel Pipe

ASTM A53 Seamless Steel Pipe

ASME SA53 Hot Dipped Galvanized Pipe

ASTM A53 Steel Tube

ASTM A53 Gr B ERW Tube

ASTM A53 type E pipe

ASTM A53 Welded Steel Pipe

Longma is one of the leading ASTM A53 GR.B ERW/Seamless Steel Pipe manufacturer since 2003

- Longma is one of the leading ASTM A53 GR.B ERW/Seamless Steel Pipe manufacturer since 2003.

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

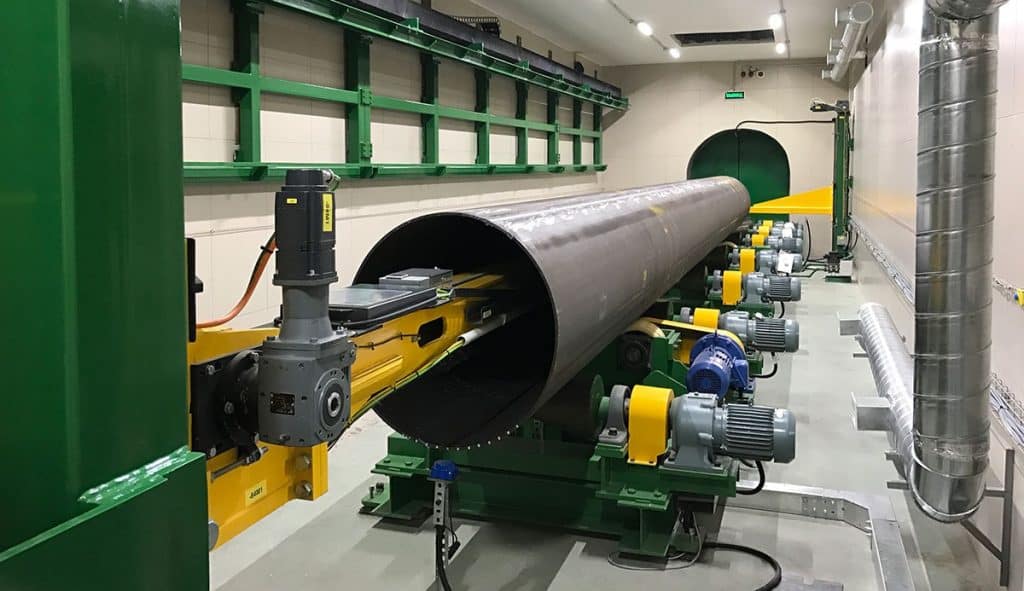

ASTM A53 ERW Steel Pipes Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

X-Ray Testing

Ultrasonic Testing

Tack Welding

Plate Ultrasonic Testing

Pipe Forming

Pipe End Bevelling

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For ASTM A53 ERW Steel Pipes

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For ASTM A53 ERW Steel Pipes

Chemical Properties %

| Grade | C, max | Mn, max | P, max | S, max | Cu*, max | Ni*, max | Cr*, max | Mo*, max | V*, max | |

|---|---|---|---|---|---|---|---|---|---|---|

| Type S(Seamless) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type E (Electric-resistance Welded) | A | 0.25 | 0.95 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

| B | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 | |

| Type F (Furnace-welded) | A | 0.3 | 1.2 | 0.05 | 0.05 | 0.4 | 0.4 | 0.4 | 0.15 | 0.08 |

Note: The total composition for these five elements shall not exceed 1.00%.

Mechanical Properties comparison

| Grade A | Grade B | |

|---|---|---|

| Tensile Strength, min., psi, (MPa) | 48,000 (330) | 60,000 (415) |

| Yield Strength, min., psi, (MPa) | 30,000 (205) | 35,000 (240) |

Note: This is summarized information from ASME Specification A53. Please refer to the specific Standard or Specification or contact us for more details.

Outside Diameter: +1/64″ (0.40mm) for size up to & including NPS 1-1/2″ and +1% of the specified 0.D.for NPS 2″ & above

Thickness: Minimum wall thickness 125% max under the specified wall thickness and not specified on positive side

Weight: +10% of specified weight

Length: 1.5 to 8.0 Mtr (5FT to 25FT) for black & galvanized pipes and 3.0 to 12.8 Mtr (10FT to 42FT) for black pipes NPS 3″ to 8″

Straightness: As mutually agreed with the client

End Finish: Plain Ends (Square Cut); Bevel Ends (Angle 30′ -0/+5); Threaded with or without coupling; Roll grooved.

- Construction: the pipeline underneath, the groundwater, and the hot water transportation.

- Mechanical processing, bearing sleeves, processing machinery parts, etc.

- Electrical: Gas delivery, Hydroelectric power fluid pipeline

- Anti-static tubes for wind power plants, etc.

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. What’s ASTM A53?

ASTM A53 specification covers seamless and welded black and hot-dipped galvanized steel pipe in NPS 1/8 to NPS 26. The steel categorized in this standard must be open-hearth, basic-oxygen or electric-furnace processed and must have the following chemical requirements: carbon, manganese, phosphorus, sulfur, copper, nickel, chromium, molybdenum, and vanadium. The tubing shall undergo a seamless or welding process. Tension, bend, and flattening tests shall be performed to make sure that it must adhere to the mechanical properties of the standard. The hydrostatic test shall be applied, without leakage through the weld seam or the pipe body. Nondestructive electric test shall be made to make sure that the full volume of the pipe must be in accordance with the standard. The purchaser shall have the right to perform any of the inspections and tests set forth in this specification where deemed necessary to ensure that the pipe conforms to the specified requirements.

2. What is the application range of ASTM A53?

Applications

1. Construction: the pipeline underneath, the groundwater, and the hot water transportation.

2. Mechanical processing, bearing sleeves, processing machinery parts, etc.

3. Electrical: Gas delivery, Hydroelectric power fluid pipeline

4. Anti-static tubes for wind power plants, etc.3. What is the difference between ASTM A53 and A36?

A53 is generally used for low-pressure plumbing applications, while A36 is popular for structural applications. Additionally, A36 has a higher tensile strength and yield strength than A53, allowing it to withstand higher stress loads.

4. What are the different types of ASTM A53 pipe?

The following types & grades of A53 pipe are covered within the ASTM A53 specification:

Type F – Furnace-butt-welded, continuous welded Grade A.

Type E- Electric-resistance-welded, Grades A and B.

Type S- Seamless, Grades A and B.5. Is ASTM A53 a low carbon steel?

ASTM A53 is a standard specification for seamless and welded black and hot-dipped galvanized steel pipe. It has a maximum carbon content of 0.30% and a maximum manganese content of 1.20%, making it a low-carbon steel with good strength and toughness.

6. What is the yield strength of ASTM A53 pipe?

ASTM A53 is a pipe specification and is intended to be used in mechanical and pressure applications. The specified yield strength of A500 Grade C (the most commonly available grade) is 46 ksi. The specified yield strength of A53 Grade B is 35 ksi.

Featured Case For ASTM A53 ERW Steel Pipes

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.