- 1. Overview of ASTM A671 Steel Pipes

- 2. Overview of Common Steel Pipe Standards

- 3. Detailed Comparison of ASTM A671 Steel Pipes with Other Standards

- 4. Selecting the Right Steel Pipe Standard Based on Application Scenarios

- 5. Quality Control Requirements and International Standards for ASTM A671 Steel Pipes

- 6. ASTM A671 Steel Pipes Market Trends and Future Development

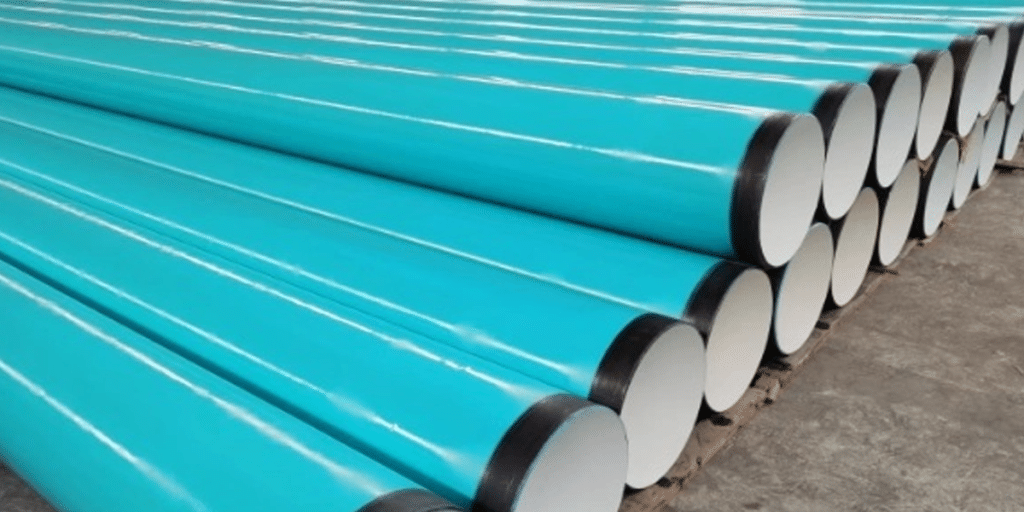

In the global energy transportation and industrial infrastructure sectors, ASTM A671 steel pipes have become the preferred choice for many projects due to their exceptional pressure resistance, excellent corrosion resistance, and wide range of applications. As a leading ERW/LSAW steel pipe manufacturer in China, Hebei Longma Steel Pipe Manufacturing Co., Ltd.

(LONGMA) leverages advanced production technology and stringent quality control to supply high-quality ASTM A671 steel pipes, meeting the demanding requirements of oil and gas transportation, cross-border energy pipelines, and the water treatment industry. This guide provides an in-depth analysis of the advantages of ASTM A671 steel pipes and compares them with other steel pipe standards, helping customers make precise selections to ensure the efficiency and long-term stability of their projects!

Overview of ASTM A671 Steel Pipes

ASTM A671 is a submerged arc-welded (SAW) steel pipe standard designed for applications requiring high-pressure resistance at ambient and low temperatures. This standard specifies carbon steel and low-alloy steel welded pipes, typically manufactured using the submerged arc welding (SAW) process and subjected to post-weld heat treatment to enhance performance.

Key Features:

Diverse Material Options – ASTM A671 steel pipes are made from different grades of plate materials to suit various operational requirements.

High-Pressure Resistance – Subjected to non-destructive testing (NDT) and rigorous mechanical property evaluations to ensure safety in high-pressure applications.

Excellent Low-Temperature Performance – Suitable for cold environments, commonly used in liquefied natural gas (LNG) transportation.

Flexible Manufacturing Process – Customizable weld joint testing and impact testing to guarantee welding quality and reliability.

Applications:

Oil & Gas Transportation – Used in long-distance pipelines for stability and corrosion resistance.

Cross-Border Energy Pipelines – Compliant with international standards for offshore and onshore transmission.

Water Treatment Pipelines – Ideal for corrosion-resistant piping, ensuring long-term operation of water supply systems.

Pressure Vessels & Boilers – Suitable for high-temperature and high-pressure environments, such as power plants and chemical industries.

Overview of Common Steel Pipe Standards

In the global steel pipe industry, different engineering and industrial applications require compliance with international standards to ensure safety, durability, and suitability. Below are some commonly used steel pipe standards and their key characteristics:

1. ASTM A671 (Electric Arc-Welded Steel Pipe)

Key Features: Suitable for high-pressure applications at ambient and low temperatures, manufactured using the submerged arc welding (SAW) process, and may undergo post-weld heat treatment.

Applications: Oil and gas transportation, cross-border energy pipelines, water treatment pipelines, boilers, and pressure vessels.

2. ASTM A672 (Electric Arc-Welded Steel Pipe for High-Temperature Pressure Service)

Key Features: Similar to ASTM A671 but specifically designed for high-temperature and high-pressure environments, such as boilers and thermal systems.

Applications: Petrochemical industry, power plants, steam pipelines.

3. API 5L (Steel Pipes for Oil and Gas Transportation)

Key Features: Designed specifically for oil and natural gas pipelines, available in seamless and welded options, and classified into PSL1 and PSL2, with PSL2 requiring stricter quality standards.

Applications: Onshore and offshore oil and gas pipelines, energy transportation projects.

4. AS 1163 (Australian Structural Steel Pipe Standard)

Key Features: Used in the Australian market for structural steel pipes, covering different strength grades, mainly for construction and infrastructure projects.

Applications: Building structures, bridges, mechanical equipment manufacturing.

5. ASTM A53 (General-Purpose Carbon Steel Pipe)

Key Features: Widely used in low-pressure and moderate-temperature environments, available in seamless or welded forms, and suitable for general fluid transportation and structural applications.

Applications: Water supply pipelines, building support structures, low-pressure fluid transport.

6. ASTM A106 (High-Temperature Seamless Carbon Steel Pipe)

Key Features: Designed for high-temperature applications, manufactured as seamless pipes, and widely used in boilers, pressure pipelines, and heat exchangers.

Applications: High-temperature piping systems in refineries, chemical plants, and power stations.

Detailed Comparison of ASTM A671 Steel Pipes with Other Standards

1. Performance Comparison

ASTM A671 steel pipes offer excellent pressure resistance, making them suitable for ambient and low-temperature environments while handling high-pressure applications. They are widely used in oil and gas transmission, water treatment pipelines, and boiler systems. In contrast, ASTM A672 is designed for high-temperature and high-pressure environments, such as steam pipelines and petrochemical industries. API 5L is primarily used for long-distance oil and gas pipelines, with pressure ratings varying by PSL1 and PSL2 grades. ASTM A106 is ideal for high-temperature and high-pressure fluid transport, while ASTM A53 is suitable for low to medium-pressure fluid transport and structural support. AS 1163 is mainly used for structural applications in the construction industry.

2. Material and Manufacturing Process Comparison

ASTM A671 steel pipes are manufactured using the submerged arc welding (SAW) process with different grades of carbon steel plates. They undergo post-weld heat treatment (such as normalizing or tempering) to enhance their mechanical properties. ASTM A672 follows a similar material and welding process but is designed for high-temperature applications.

API 5L steel pipes are available in seamless (SMLS), electric resistance welded (ERW), or spiral submerged arc welded (SSAW) types, with different grades of carbon steel. PSL2 grades require stricter quality control. ASTM A106 pipes are seamless, designed for high-temperature and high-pressure applications. ASTM A53 pipes can be seamless (SMLS) or electric resistance welded (ERW), mainly used for low-pressure transmission or structural applications. AS 1163 pipes are typically low-carbon or alloy steel for construction use.

3. Welding Method Comparison

ASTM A671 pipes use the submerged arc welding (SAW) process, which can be single or double-sided. They usually require post-weld heat treatment to enhance weld uniformity and crack resistance. ASTM A672 follows the same welding method but is designed for higher temperature environments.

API 5L pipes have multiple welding methods, including ERW (electric resistance welding), LSAW (longitudinal submerged arc welding), and SSAW (spiral submerged arc welding), with different quality requirements for PSL1 and PSL2 grades. ASTM A106 pipes do not require welding as they are seamless steel pipes, while ASTM A53 pipes can be seamless or ERW-welded. AS 1163 pipes are typically ERW-welded, making them suitable for structural applications.

Selecting the Right Steel Pipe Standard Based on Application Scenarios

1. Oil and Gas Transmission Pipelines

Recommended Standard: API 5L (PSL1 & PSL2)

Reason: API 5L pipes are designed for long-distance oil and gas transportation. They offer high strength, corrosion resistance, and durability. PSL2 grades provide stricter quality control for enhanced performance in demanding environments.

Pipe Types: Available in seamless (SMLS), electric resistance welded (ERW), longitudinal submerged arc welded (LSAW), and spiral submerged arc welded (SSAW).

Typical Applications: Cross-country oil and gas pipelines, offshore drilling, and natural gas distribution.

2. High-Pressure and Low-Temperature Applications (Cryogenic Environments)

Recommended Standard: ASTM A671

Reason: ASTM A671 pipes are manufactured using submerged arc welding (SAW) and undergo post-weld heat treatment to improve toughness. They are ideal for low-temperature, high-pressure transmission.

Pipe Types: Fabricated from carbon steel plates with different class options for varying strength levels.

Typical Applications: Low-temperature oil, gas, and water pipelines, pressure vessels, and cryogenic processing plants.

3. High-Pressure and High-Temperature Applications

Recommended Standard: ASTM A672

Reason: ASTM A672 pipes are similar to A671 but are designed for higher temperature and pressure conditions. They are commonly used in steam pipelines and petrochemical processing.

Pipe Types: SAW-welded carbon steel pipes with post-weld heat treatment.

Typical Applications: Steam pipelines, power plant boilers, petrochemical plants, and high-temperature industrial piping.

4. High-Temperature and High-Pressure Fluid Transmission

Recommended Standard: ASTM A106

Reason: ASTM A106 pipes are seamless and provide excellent performance in high-temperature, high-pressure conditions. They are widely used in power plants and refineries.

Pipe Types: Seamless carbon steel pipes with Grades A, B, and C for different strength levels.

Typical Applications: Boiler piping, steam transmission, oil refining, and chemical processing.

5. Low-Pressure Fluid Transportation and Structural Applications

Recommended Standard: ASTM A53

Reason: ASTM A53 pipes are suitable for low-pressure fluid transport as well as structural support. They are available in both seamless and ERW-welded options.

Pipe Types: Available in Grade A and Grade B, with black, galvanized, and bare surface finishes.

Typical Applications: Water pipelines, fire protection systems, scaffolding, and building structures.

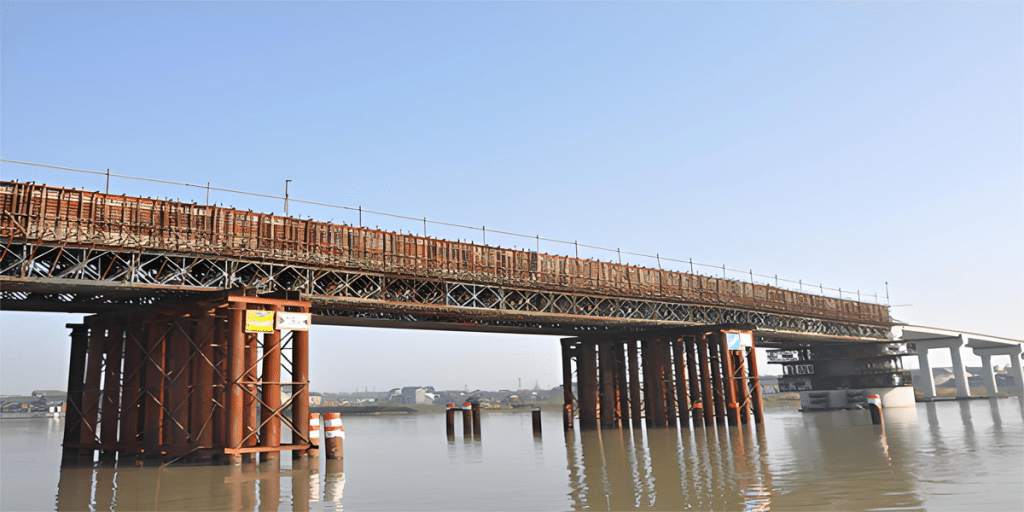

6. Structural Applications (Construction, Bridges, and Machinery)

Recommended Standard: AS 1163

Reason: AS 1163 is an Australian standard for structural steel pipes, offering high strength and weldability. It is widely used in engineering and construction projects.

Pipe Types: Carbon steel pipes with ERW welding, classified into different grades such as C250, C350, and C450.

Typical Applications: Steel frameworks, bridges, heavy machinery, and infrastructure projects.

Quality Control Requirements and International Standards for ASTM A671 Steel Pipes

1. Key Quality Control Requirements of ASTM A671 Steel Pipes

(1) Strict Material and Manufacturing Process Control

High-quality carbon steel plates are selected to ensure material purity and consistent mechanical performance.

Submerged Arc Welding (SAW) is used for uniform and strong weld seams, suitable for long-distance pipelines.

Post-Weld Heat Treatment (PWHT) is applied to eliminate residual stresses and enhance the pipe’s durability.

(2) Mechanical Performance and Dimensional Accuracy Testing

Tensile, impact, and hardness tests ensure the stability of the steel pipes under various operating conditions.

Wall thickness, diameter, and straightness are precisely measured to meet ASTM A671 standards, minimizing installation errors.

(3) Rigorous Pressure and Leak Testing

Hydrostatic and gas leak tests ensure the pipe remains leak-free under high pressure.

X-ray and ultrasonic testing (RT & UT) are conducted to identify any potential defects in the welds.

(4) Compliance with Environmental Requirements, Supporting Sustainability

Low-carbon emission production processes optimize energy consumption and reduce the carbon footprint.

Eco-friendly anti-corrosion coatings are available, minimizing harmful emissions.

Steel scrap recycling is practiced, complying with the ISO 14001 Environmental Management System.

2. International Standards Compliance of ASTM A671 Steel Pipes

To meet global engineering needs, ASTM A671 steel pipes comply with several international standards, including:

ASME Standards: Applicable to process piping (B31.3), liquid transmission pipelines (B31.4), and natural gas pipelines (B31.8).

API 5L: Shares similar applications with ASTM A671, used for oil and gas transmission pipelines.

ISO 3183: The international equivalent of API 5L, widely used in cross-border oil and gas transmission projects.

EN 10217, JIS G3454, GB/T 9711: Comply with European, Japanese, and Chinese pressure pipeline standards, suitable for global markets.

ASTM A671 Steel Pipes Market Trends and Future Development

1. Rising Demand in Energy and Infrastructure Projects

Oil and Gas Industry Growth: With the ongoing need for energy transmission, particularly in oil and gas pipelines, the demand for high-performance pipes like ASTM A671 is expected to rise. The ability of these pipes to withstand low temperatures and moderate pressure makes them ideal for long-distance oil and gas transmission in challenging environments.

Global Infrastructure Expansion: As urbanization and industrialization continue, there is a significant rise in demand for water pipelines, industrial infrastructure, and corrosion-resistant piping systems, driving the need for ASTM A671 steel pipes that offer reliability and durability.

2. Technological Advancements in Manufacturing

Improved Production Techniques: The development of more advanced submerged arc welding (SAW) techniques and post-weld heat treatment (PWHT) processes is enhancing the quality of ASTM A671 pipes, making them even more reliable for critical applications.

Automation and Industry 4.0: The steel pipe manufacturing sector is incorporating smart manufacturing techniques such as automation, real-time quality control systems, and digital tracking to ensure the highest quality standards while reducing production costs.

3. Environmental Regulations and Sustainability

Sustainable Practices: As environmental regulations become more stringent, the steel industry is increasingly focusing on eco-friendly manufacturing practices. ASTM A671 steel pipes produced with low-carbon emissions, energy-efficient processes, and recyclable materials are becoming more attractive in a market focused on sustainability.

Green Building Initiatives: The growing popularity of green construction and sustainable building practices is increasing demand for environmentally responsible materials, including steel pipes that are corrosion-resistant and long-lasting, which supports the future demand for ASTM A671 pipes.

4. Market Growth in Developing Regions

Asia-Pacific and Middle East Markets: Countries like China, India, and those in the Middle East are investing heavily in infrastructure and energy projects, which is fueling the demand for ASTM A671 steel pipes. These regions are experiencing rapid industrialization, and the demand for reliable and durable steel pipes is growing.

Expanding Oil and Gas Exploration: As new oil and gas fields are being developed, particularly in regions like Africa, Latin America, and the Arctic, the need for robust and high-performance steel pipes like ASTM A671 is expected to increase significantly.

5. Increased Customization and Application-Specific Solutions

Tailored Solutions: The trend toward customized steel pipe solutions for specific applications, such as highly resistant pipes for harsh environments or specialized coatings for corrosion protection, will drive innovation and product development. ASTM A671 steel pipes will continue to evolve, offering more application-specific options for diverse industries.

Integration with Other Materials: In some applications, combining ASTM A671 steel pipes with advanced materials, like composite coatings or polymer linings, could improve performance, especially in terms of corrosion resistance and extended lifespan.

6. Competitive Landscape and Market Challenges

Rising Competition: As the demand for steel pipes continues to rise, the global market for ASTM A671 steel pipes is becoming increasingly competitive. Manufacturers must innovate and improve efficiency to meet the growing demand while maintaining competitive pricing.

Raw Material Price Volatility: The price fluctuations of key raw materials like carbon steel could impact the manufacturing cost of ASTM A671 steel pipes. This volatility may require manufacturers to adopt more cost-effective procurement strategies and innovative production processes to maintain profitability.

In conclusion, ASTM A671 steel pipes are poised to play a vital role in the global market due to their exceptional mechanical properties, suitability for demanding applications, and the ongoing trend toward sustainability. As industries such as oil and gas, water treatment, and infrastructure continue to expand, the demand for high-performance, corrosion-resistant, and durable steel pipes will only increase. The continued evolution of manufacturing technologies, coupled with the growing emphasis on environmental responsibility, positions ASTM A671 steel pipes as a reliable and forward-thinking choice for critical infrastructure projects worldwide!

As manufacturers, such as Hebei Longma Steel Pipe Manufacturing Co., Ltd., continue to innovate and enhance their production processes, ASTM A671 steel pipes will remain at the forefront of the steel pipe industry, supporting the development of modern infrastructure and energy systems. By adhering to rigorous international standards and embracing sustainability, the future of ASTM A671 steel pipes is bright, paving the way for a more efficient and environmentally conscious global pipeline network!