- 1. Overview of ASTM A691 Standard

- 2. Manufacturing Process and Material Characteristics of ASTM A691 Steel Pipes

- 3. An Overview of ASTM A691 Grade and Class Classification

- 4. ASTM A691 Steel Pipe Industry Applications

- 5. How to Select the Right ASTM A691 Steel Pipe?

- 6. Analysis of the Market Trends and Future Development of ASTM A691 Steel Pipe

In modern industry, steel pipes are a crucial component in numerous infrastructures and systems. Whether it’s in the transportation of oil and gas, or in high-temperature and high-pressure applications, ASTM A691 steel pipes stand out for their exceptional performance and reliable quality, making them a top choice across various sectors. But what exactly makes ASTM A691 steel pipes a preferred material among many standards? In this article, we will delve into the manufacturing process, material properties, and key industry applications of ASTM A691 steel pipes, offering a comprehensive understanding of why these pipes excel in demanding environments!

Overview of ASTM A691 Standard

ASTM A691 is a standard developed by ASTM International (formerly known as the American Society for Testing and Materials) that outlines the technical requirements for carbon and alloy steel welded pipes used in high-temperature and high-pressure services. This standard applies to steel pipes intended for use in demanding environments, particularly in industries such as oil and gas pipelines, chemicals, and energy, power plants, particularly in pipeline systems requiring high pressure and temperature resistance, ensuring safety and long-term performance in transport systems! Under the ASTM A691 standard, pipes are typically made from carbon steel or low-alloy steel, offering high tensile strength, good toughness, and resistance to corrosion, making them suitable for harsh operating conditions. The standard provides detailed specifications for chemical composition, mechanical properties, welding requirements, and other technical parameters to ensure the stability and reliability of the product in real-world applications!

Key Features:

Materials: Includes carbon steels, low-alloy steels, with common grades like ASTM A691 Gr. 65, Gr. 70, etc.

High-Temperature and High-Pressure Performance: Designed for use in environments where both high temperatures and high pressures are present.

Manufacturing Process: Pipes are manufactured through welding processes, such as electric arc welding, with specific requirements for the strength of welded joints.

Quality Control: The standard sets strict requirements for dimensions, wall thickness, tolerances, and surface quality to ensure the pipe’s stability and safety.

Manufacturing Process and Material Characteristics of ASTM A691 Steel Pipes

Manufacturing Process of ASTM A691 Steel Pipes

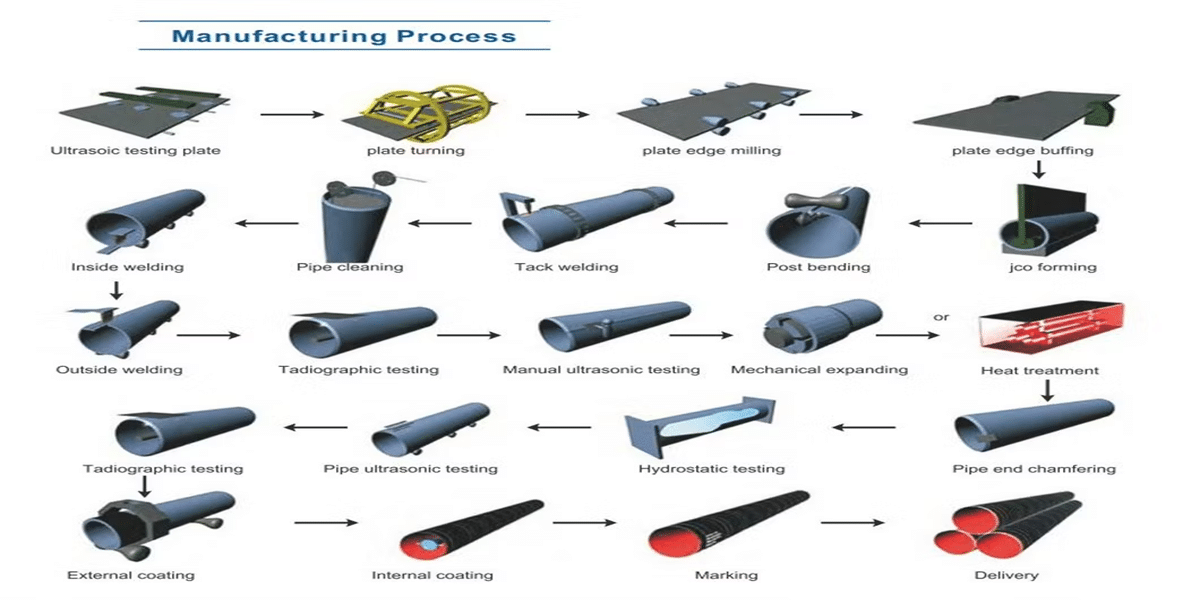

ASTM A691 steel pipes are manufactured using the Electric Fusion Welding (EFW) process, which is well-suited for high-temperature and high-pressure applications. The detailed process includes:

Material Selection: High-quality carbon steel or low-alloy steel is selected as the raw material, conforming to ASTM A691 grades (e.g., Gr. 65, Gr. 70) to meet the demands for strength and toughness.

Pipe Forming: Steel plates or strips are rolled into a cylindrical shape, and the edges are prepared for welding. The edges are aligned precisely to ensure consistent and robust welds.

Electric Fusion Welding (EFW): The welding process uses an electric arc or current to melt the edges of the steel plate, forming a fusion bond. This ensures that the weld is as strong as the base material, making it ideal for manufacturing thick-walled and large-diameter pipes.

Heat Treatment: Post-welding, the pipes undergo heat treatment processes such as normalizing, tempering, or stress relieving. This step improves mechanical properties and relieves stresses induced during welding, ensuring stability under high-temperature and high-pressure conditions.

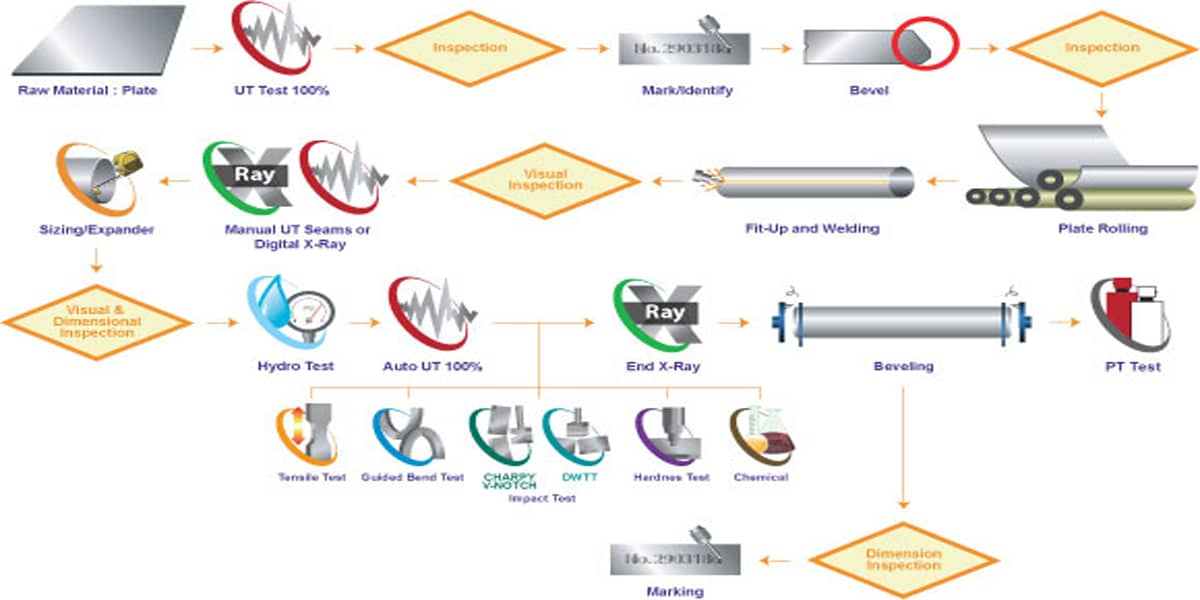

Inspection and Testing:

Nondestructive Testing (NDT): Ultrasonic or X-ray inspection is performed to detect any flaws in the welds and ensure their integrity.

Mechanical Testing: Includes tensile, impact, hardness, and bend tests to verify the mechanical performance of the pipes.

Dimensional and Surface Inspection: Ensures the pipe’s diameter, wall thickness, and surface finish meet the technical specifications.

Final Finishing: The pipes are cleaned and may be coated for corrosion resistance as per client requirements. Hydrostatic testing is also conducted to ensure the pipes can withstand high pressure without leaks.

Material Characteristics of ASTM A691 Steel Pipes

1. Material Properties

ASTM A691 steel pipes are renowned for their excellent material properties, making them ideal for high-temperature and high-pressure applications. The key features include:

High Strength: The tensile strength of ASTM A691 steel pipes varies by grade, typically ranging from 65 ksi (Grade 65) to 70 ksi (Grade 70). This high strength enables the pipes to withstand the demands of transporting high-pressure fluids.

Heat Resistance: The material is specifically engineered to maintain stable mechanical properties in elevated-temperature environments, making it suitable for steam pipelines, power plants, and refinery systems.

Corrosion Resistance: Certain grades are alloyed with elements like chromium and molybdenum, enhancing oxidation resistance and corrosion resistance, enabling long-term use in corrosive environments.

Excellent Toughness and Impact Resistance: These pipes exhibit superior toughness, allowing them to perform reliably under low-temperature or high-pressure impact conditions, ensuring safety and durability.

Reliable Weldability: Manufactured using the Electric Fusion Welding (EFW) process, ASTM A691 pipes ensure that the welds are as strong as the base material, suitable for demanding industrial environments.

Stable Chemical Composition: Materials in ASTM A691 pipes include carbon, manganese, chromium, molybdenum, and vanadium. These elements enhance the pipe’s strength, heat resistance, and creep resistance, making them ideal for complex working conditions.

2. Classification

According to the ASTM A691 standard, steel pipes are classified based on the base material type and mechanical performance. Common grades include:

Grade 1: Made of plain carbon steel, primarily used for general industrial applications and suitable for moderate temperature and pressure conditions.

Grade 5, 9, 11: Alloyed with elements such as chromium and molybdenum to enhance heat resistance, these grades are suitable for high-temperature and high-pressure conditions, commonly used in steam pipelines and boiler systems.

Grade 22: Enhanced with molybdenum, this grade offers higher heat resistance and creep strength, making it ideal for high-temperature chemical processing equipment and power plant applications.

Grade 91: Composed of 9% chromium and 1% molybdenum, this grade delivers exceptional oxidation resistance and strength, making it ideal for ultra-high-temperature and ultra-high-pressure environments, such as supercritical power station boilers.

An Overview of ASTM A691 Grade and Class Classification

1. Grade Classification and Performance Comparison

ASTM A691 steel pipes are classified based on the chemical composition and mechanical properties of the base material, with common grades such as Grade 1-1/4Cr and Grade 2-1/4Cr.

Grade 1-1/4Cr contains 1.25% chromium (Cr) and small amounts of molybdenum (Mo). It is known for its good oxidation resistance and moderate heat resistance, making it suitable for medium-temperature and medium-pressure applications. This grade is cost-effective and commonly used in the petroleum and natural gas industries for medium-temperature pipeline systems and medium-pressure steam transport pipelines.

Grade 2-1/4Cr, with 2.25% chromium (Cr) and small amounts of molybdenum (Mo), offers enhanced heat resistance, oxidation resistance, and creep resistance compared to Grade 1-1/4Cr. This grade is ideal for high-temperature and high-pressure applications, such as high-temperature steam pipelines, boiler systems, and high-temperature chemical processing equipment.

In terms of performance, Grade 2-1/4Cr is superior in heat and mechanical properties, making it more suitable for harsh working conditions. Grade 1-1/4Cr, on the other hand, is more economical and better suited for less extreme environments.

2. Classification Based on Manufacturing Class

ASTM A691 pipes are further classified based on their manufacturing class (Class), which defines the welding and heat treatment processes to suit various pressure and temperature conditions. The classes range from Class 10 to Class 100, with each class designed for specific pressure and temperature applications.

Class 10 pipes are designed for low to medium-pressure and low-temperature applications. These pipes undergo minimal heat treatment and are primarily used in general industrial applications, such as non-critical pipelines, with lower costs.

Class 20 pipes are suitable for medium-pressure and medium-temperature environments. They undergo partial heat treatment to improve mechanical properties, making them appropriate for industrial pipeline systems with moderate pressure and temperature requirements.

Class 30 to Class 60 pipes are designed for medium to high-pressure and medium to high-temperature conditions. These pipes undergo full heat treatment after welding, enhancing weld performance. They are commonly used in industrial and energy pipelines where moderate to high-pressure and temperature conditions are present.

Class 70 to Class 100 pipes are designed for high-pressure and high-temperature environments. They undergo stringent heat treatment and testing to ensure reliability under extreme conditions. These high-performance pipes are widely used in critical pipeline systems in industries like petrochemical, power plants, and high-temperature steam transport systems.

ASTM A691 Steel Pipe Industry Applications

1. Industry Applications of ASTM A691 Steel Pipes

ASTM A691 steel pipes, known for their exceptional strength, heat resistance, and pressure endurance, are widely used across various industries. These pipes are specifically designed for high-temperature, high-pressure environments, making them ideal for applications in energy, petrochemical, and chemical industries. Below are some of the key industry applications:

1.1. Power Generation Industry

High-Temperature Steam Pipelines: ASTM A691 steel pipes are commonly used for transporting steam at high temperatures and pressures, such as in supercritical and ultra-supercritical power plants. These pipes can withstand extremely high operating temperatures (up to 600°C or more), making them essential for the efficient functioning of power generation systems.

Boiler Systems: In both fossil fuel and nuclear power plants, ASTM A691 pipes are used to transport water and steam through the boiler and turbine systems, where the pipes need to withstand high pressure and temperature without degrading.

1.2. Oil and Gas Industry

Crude Oil and Natural Gas Pipelines: The oil and gas industry relies heavily on ASTM A691 pipes for transporting crude oil, natural gas, and other liquids under high pressure. The enhanced corrosion resistance and heat resistance make ASTM A691 pipes ideal for both offshore and onshore pipeline systems.

Refinery Units: In refinery units, where elevated temperatures and harsh chemical processes occur, ASTM A691 pipes are used for transporting hot fluids, steam, and chemicals, contributing to the safe operation of refining processes.

1.3. Chemical Processing Industry

High-Pressure Chemical Transport: ASTM A691 steel pipes are often employed in high-pressure chemical systems, including those found in fertilizer plants, petrochemical refineries, and chemical reactors. These pipes help safely carry fluids and gases that are heated or under pressure, where corrosion resistance and long-term durability are crucial.

Corrosive Fluid Handling: For environments involving corrosive fluids, ASTM A691 steel pipes provide the necessary strength and resistance to prevent material degradation and failure over time.

2. Case Study: ASTM A691 Steel Pipe in a Major Project

2.1. Project Overview: Supercritical Power Plant in China

In one of the major power plants in China, an ultra-supercritical steam power plant was being developed to enhance energy efficiency and reduce environmental impact. The project aimed to generate power at higher efficiencies by operating at higher temperatures and pressures, which meant the materials used in the plant needed to withstand these harsh conditions.

2.2. ASTM A691 Steel Pipe Usage

For the plant’s high-pressure steam lines and boiler systems, Grade 2-1/4Cr ASTM A691 steel pipes were chosen due to their exceptional heat resistance and high creep strength. These pipes were used in areas where steam temperatures exceeded 600°C, and high pressures up to 30 MPa were present.

2.3. Performance and Results

The use of ASTM A691 pipes in this power plant ensured that the steam transport systems could operate efficiently without the risk of pipe failure under extreme conditions. These pipes also contributed to the overall durability of the plant, reducing maintenance costs and ensuring the plant’s long-term performance. The installation of the high-grade ASTM A691 steel pipes played a key role in achieving the plant’s goal of operating with improved energy efficiency and reduced carbon emissions.

How to Select the Right ASTM A691 Steel Pipe?

Selecting the appropriate ASTM A691 steel pipe requires considering multiple factors to ensure the pipe meets the specific needs of the application, particularly in high-temperature, high-pressure, and corrosive environments. Here are the key factors to consider when choosing the right ASTM A691 steel pipe:

1. Determine Application Requirements

First, it is important to understand the industrial environment and operating conditions where the steel pipe will be used. Different industries (such as power, oil and gas, chemical processing, etc.) and applications (such as high-temperature steam pipelines, oil and gas transportation pipelines, or chemical transportation pipelines) have different performance requirements for steel pipes. The key points to consider include:

Temperature Requirements: The operating temperature the steel pipe will endure. Select an appropriate grade of steel pipe (e.g., Grade 1-1/4Cr, Grade 2-1/4Cr) based on the temperature. Higher temperatures usually require pipes with better heat resistance.

Pressure Requirements: The operating pressure of the application. High-pressure environments require pipes that can withstand greater strength and pressure.

Corrosive Environment: Whether the steel pipe will be exposed to corrosive substances or harsh environmental conditions, such as marine environments or chemical transport. Choose pipes with good corrosion resistance and oxidation resistance.

2. Choose the Appropriate Steel Pipe Grade

ASTM A691 steel pipes are available in various grades based on different chemical compositions and mechanical properties. Selecting the appropriate grade is key to ensuring the pipe has sufficient strength and durability in high-temperature, high-pressure environments. Common grades include:

Grade 1-1/4Cr: Suitable for medium temperature and medium-pressure applications, commonly used in oil and gas transportation and chemical industries.

Grade 2-1/4Cr: Suitable for high-temperature and high-pressure applications, commonly used in the power industry for supercritical and ultra-supercritical steam pipelines, boiler systems, etc.

Grade 5: Suitable for even higher temperature and pressure environments, typically used in high-temperature, high-pressure systems in the petrochemical industry.

3. Prioritizing Performance Requirements: First, evaluate the performance requirements based on the specific needs of the project (such as temperature, pressure, corrosive environment, etc.). If a project requires extremely high performance, such as working in ultra-high temperature or highly corrosive environments, it may be necessary to select higher-grade (such as Grade 5 or above) and higher-class (Class 70 or above) steel pipes, which will increase costs. However, these additional investments are essential to ensure safety and long-term operation, especially in critical infrastructure or high-risk environments.

4. Budget Constraints: Budget is a practical issue for many projects, so it is important to assess which performance features are essential and which can be moderately compromised. For some applications that do not require extreme performance (such as medium temperature or pressure environments), lower-grade steel pipes (such as Grade 1-1/4Cr or Grade 2-1/4Cr) may suffice, and these pipes are more cost-effective. This approach allows savings without compromising project safety and reliability.

5. Quality and Certification: Ensure that the selected ASTM A691 steel pipes meet the relevant quality standards and certifications. Choose pipes from certified manufacturers and suppliers to ensure they meet international standards (such as ASTM, ASME) and have undergone rigorous testing and inspection, ensuring their reliability.

Analysis of the Market Trends and Future Development of ASTM A691 Steel Pipe

1. Technological Innovation

Technological innovations have a profound impact on the market development of ASTM A691 steel pipes. With continuous advancements in material science and manufacturing technologies, the performance and production processes of ASTM A691 steel pipes have significantly improved. Below are the key changes driven by technological innovation:

Improved Alloy Composition and Heat Treatment Processes: With the development of material science, the alloy composition and heat treatment processes of ASTM A691 steel pipes have been optimized. These innovations significantly enhance the steel pipe’s resistance to creep and corrosion, allowing it to maintain superior performance in extreme conditions. For example, new alloy materials can greatly improve the creep resistance and corrosion resistance of steel pipes, extending their lifespan in high-temperature and high-pressure environments.

Advanced Manufacturing Processes: In terms of production processes, advances in electric arc furnace steelmaking, refining processes, and efficient welding technologies have improved the quality and production efficiency of ASTM A691 steel pipes. These technologies enhance the dimensional accuracy, surface finish, and overall structural stability of the steel pipes, making them suitable for more demanding applications.

3D Printing and Customized Production: With the rise of 3D printing and digital manufacturing technologies, customized production of ASTM A691 steel pipes is becoming possible. This provides more options for projects with special requirements, particularly in complex pipeline designs and applications requiring custom sizes. Customized production can effectively improve construction efficiency and adaptability to specific project needs.

Sustainable Manufacturing Technologies: As environmental sustainability becomes increasingly important, the production of ASTM A691 steel pipes will increasingly rely on low-carbon technologies and circular economy models. The use of recycled steel and low-emission manufacturing processes will become the new standard in steel pipe production, reducing carbon emissions and environmental pollution during production.

2. Industry Demand Growth

The demand for ASTM A691 steel pipes is also rapidly increasing, driven by the growth of several industries, particularly the energy, oil and gas, and chemical sectors. Below are the main factors contributing to industry demand growth:

Rapid Growth of the Power Industry: With the global demand for clean energy and efficient energy systems increasing, especially in supercritical (USC) and ultra-supercritical power plants, the demand for ASTM A691 steel pipes will continue to rise. These power plants operate at higher temperatures and pressures, and ASTM A691 steel pipes’ ability to withstand extreme conditions makes them an ideal choice. The construction of these plants will drive the continuous expansion of the ASTM A691 steel pipe market.

Expansion of the Oil and Gas Industry: As global oil and gas exploration and development projects increase, particularly deepwater oil fields, the demand for ASTM A691 steel pipes in offshore drilling, oil pipelines, and natural gas transportation will see significant growth. Offshore platforms and remote oil fields require steel pipes that can withstand extreme temperatures, pressures, and corrosive environments. ASTM A691 steel pipes, with their high strength and corrosion resistance, are the preferred material for these applications.|

Increased Demand in the Chemical Industry: With the rapid development of the global chemical industry, especially in petrochemical and fertilizer sectors, the demand for high-quality pipes is increasing. ASTM A691 steel pipes, due to their excellent resistance to chemical corrosion, high temperatures, and pressures, are widely used in pipelines and reactors within chemical plants.

Growth in Infrastructure Development: As infrastructure development accelerates in emerging markets, particularly in the Asia-Pacific, Middle East, and Africa regions, the demand for high-performance steel pipes will increase. The rapid growth of the oil, gas, and power industries in these regions will drive demand for ASTM A691 steel pipes, particularly in large-scale industrial projects and infrastructure initiatives.

Environmental Regulations and Energy Transition: As countries around the world strengthen environmental regulations and promote energy transition, particularly through the development of renewable energy and increased energy efficiency, the demand for ASTM A691 steel pipes will further rise. In highly efficient and environmentally friendly power generation and industrial manufacturing processes, ASTM A691 steel pipes will play an important role due to their superior performance under high temperature, high pressure, and corrosive conditions.

ASTM A691 steel pipes, with their exceptional resistance to high temperatures, high pressure, and corrosion, are widely used in industries such as energy, oil and gas, and chemicals, meeting the stringent demands of harsh environments. With continuous technological innovation, particularly breakthroughs in alloy materials, manufacturing processes, and customized production, the performance of ASTM A691 steel pipes has been consistently enhanced, making them a reliable choice for more complex and high-demand projects. Additionally, the growing global energy demand, accelerated infrastructure development, and increasing need for high-performance steel pipes across industries are expanding the market prospects for ASTM A691 steel pipes. In the future, as emerging markets expand and technological advancements continue, ASTM A691 steel pipes will play an increasingly important role globally, becoming a key material driving the development of the energy, oil and gas, and chemical industries. It is expected that ASTM A691 steel pipes will not only maintain their significance in the current market but also open up more application scenarios and broader market space. If you have any questions or would like to learn more about ASTM A691 steel pipes, feel free to contact us!