Blog

- All

- Knowledge

- News

In the era of smart manufacturing and the continuous upgrading of high-end equipment, the demands on material performance for machinery structures are becoming increasingly stringent. AS 1163 steel pipes, compliant with Australian/New Zealand standards, are gaining popularity due to their excellent mechanical properties, superior weldability, and exceptional durability. These pipes are now being widely applied in various machinery structural components, ranging from heavy-duty construction equipment to precision manufacturing devices. This article will explore the diverse applications of AS 1163 steel…

In the era of smart manufacturing and the continuous upgrading of high-end equipment, the demands on material performance for machinery structures are becoming increasingly stringent. AS 1163 steel pipes, compliant with Australian/New Zealand standards, are gaining popularity due to their excellent mechanical properties, superior weldability, and exceptional durability. These pipes are now being widely applied in various machinery structural components, ranging from heavy-duty construction equipment to precision manufacturing devices. This article will explore the diverse applications of AS 1163 steel… As global infrastructure development accelerates, the choice of materials has become a critical factor in determining the quality and long-term stability of engineering projects. AS 1163 steel pipes, which conform to the Australian/New Zealand standards for structural steel, have gained widespread application in bridges, buildings, transportation systems, and water infrastructure due to their exceptional strength, weldability, and durability! With the industry's increasing focus on sustainability and structural reliability, the demand for AS 1163 steel pipes continues to rise. This article…

As global infrastructure development accelerates, the choice of materials has become a critical factor in determining the quality and long-term stability of engineering projects. AS 1163 steel pipes, which conform to the Australian/New Zealand standards for structural steel, have gained widespread application in bridges, buildings, transportation systems, and water infrastructure due to their exceptional strength, weldability, and durability! With the industry's increasing focus on sustainability and structural reliability, the demand for AS 1163 steel pipes continues to rise. This article… In the modern machinery manufacturing industry, the choice of steel pipes plays a crucial role in production efficiency and product quality. As a widely used steel pipe material in mechanical structures, ASTM A500 steel pipe has earned high recognition in the industry for its outstanding performance and reliability. Whether it's used in machine frameworks, supporting structures, or in environments with high-strength loads, ASTM A500 steel pipes provide stable support and durability! As Hebei Longma Steel Pipe Manufacturing Co., Ltd., a…

In the modern machinery manufacturing industry, the choice of steel pipes plays a crucial role in production efficiency and product quality. As a widely used steel pipe material in mechanical structures, ASTM A500 steel pipe has earned high recognition in the industry for its outstanding performance and reliability. Whether it's used in machine frameworks, supporting structures, or in environments with high-strength loads, ASTM A500 steel pipes provide stable support and durability! As Hebei Longma Steel Pipe Manufacturing Co., Ltd., a… In modern engineering projects, the welding performance of steel pipes plays a critical role in ensuring the strength and stability of structures. Especially in industries such as oil, gas, and chemicals, where high-strength steel pipes are commonly used, selecting the right material and welding process is crucial. ASTM A671, A672, and A691 steel pipes are widely utilized in various industrial applications, yet their welding characteristics vary. This article will delve into the welding properties of these three types of steel…

In modern engineering projects, the welding performance of steel pipes plays a critical role in ensuring the strength and stability of structures. Especially in industries such as oil, gas, and chemicals, where high-strength steel pipes are commonly used, selecting the right material and welding process is crucial. ASTM A671, A672, and A691 steel pipes are widely utilized in various industrial applications, yet their welding characteristics vary. This article will delve into the welding properties of these three types of steel… In modern construction, infrastructure, and engineering projects, selecting the right steel pipe is crucial. ASTM A500 and ASTM A252 are two widely used standards in structural and foundation applications, each with distinct advantages. ASTM A500 is primarily used for structural support, emphasizing strength and dimensional accuracy, while ASTM A252 is designed for piling applications, focusing on durability and load-bearing capacity. As engineering projects demand higher material performance, a thorough comparison of ASTM A500 and ASTM A252 can help businesses make…

In modern construction, infrastructure, and engineering projects, selecting the right steel pipe is crucial. ASTM A500 and ASTM A252 are two widely used standards in structural and foundation applications, each with distinct advantages. ASTM A500 is primarily used for structural support, emphasizing strength and dimensional accuracy, while ASTM A252 is designed for piling applications, focusing on durability and load-bearing capacity. As engineering projects demand higher material performance, a thorough comparison of ASTM A500 and ASTM A252 can help businesses make… In modern bridge construction, ASTM A252 steel pipes have become an ideal choice for pile foundations and support structures due to their high strength, durability, and adaptability. With the rapid expansion of cross-river bridges, highways, and urban rail transit projects, the demand for high-quality piling pipes continues to grow. At the same time, green building concepts are driving the industry to focus more on corrosion resistance and sustainability. This article explores the advantages, market trends, and future prospects of ASTM…

In modern bridge construction, ASTM A252 steel pipes have become an ideal choice for pile foundations and support structures due to their high strength, durability, and adaptability. With the rapid expansion of cross-river bridges, highways, and urban rail transit projects, the demand for high-quality piling pipes continues to grow. At the same time, green building concepts are driving the industry to focus more on corrosion resistance and sustainability. This article explores the advantages, market trends, and future prospects of ASTM… With the advancement of globalization, energy, infrastructure, and industrial projects are increasingly being carried out across borders. Multinational projects often involve complex environmental conditions, stringent engineering standards, and diverse regional regulations, making the selection of high-performance steel pipes that meet international standards essential. ASTM A671, A672, and A691 steel pipes are widely used in sectors such as oil and gas transportation, power generation, offshore pipelines, and water treatment facilities due to their exceptional pressure resistance, corrosion resistance, and reliability. This…

With the advancement of globalization, energy, infrastructure, and industrial projects are increasingly being carried out across borders. Multinational projects often involve complex environmental conditions, stringent engineering standards, and diverse regional regulations, making the selection of high-performance steel pipes that meet international standards essential. ASTM A671, A672, and A691 steel pipes are widely used in sectors such as oil and gas transportation, power generation, offshore pipelines, and water treatment facilities due to their exceptional pressure resistance, corrosion resistance, and reliability. This… In the energy and power industries, the quality and durability of piping systems are of utmost importance. As a high-performance material with widespread applications, ASTM A672 steel pipes are indispensable due to their high strength, corrosion resistance, and excellent weldability. Whether in oil and gas transportation, cross-border pipeline systems, or cooling systems in the power industry, ASTM A672 steel pipes have proven their exceptional adaptability and reliability. In this article, we will explore the applications and advantages of ASTM A672…

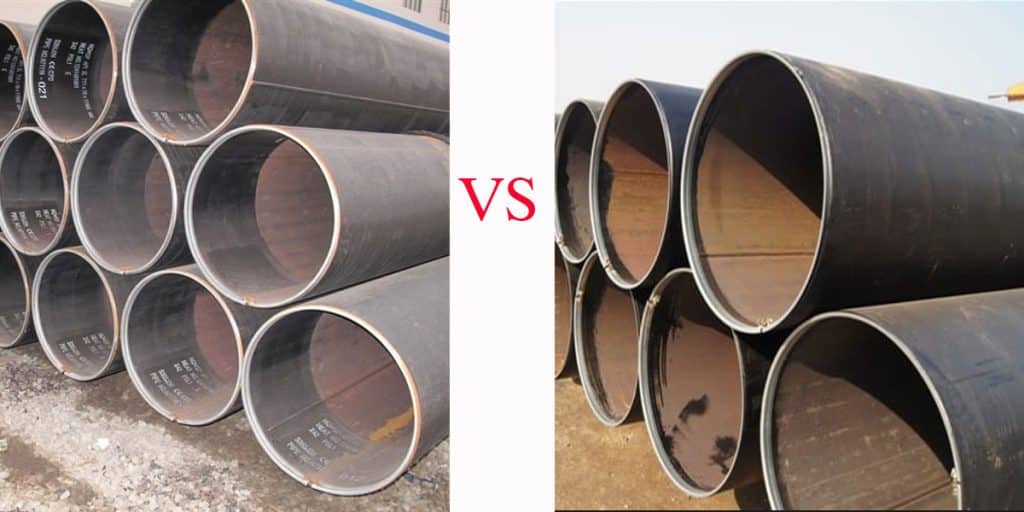

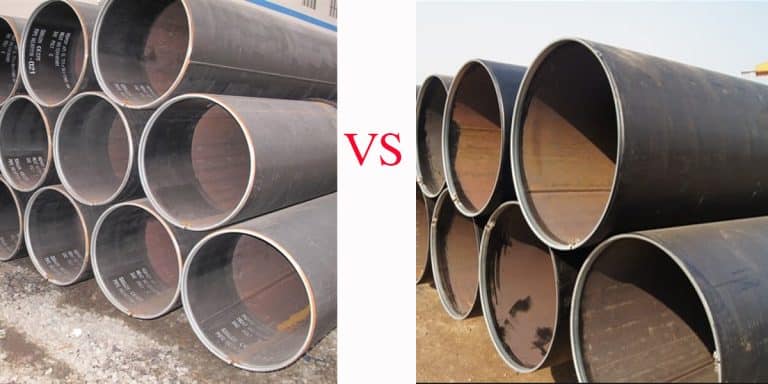

In the energy and power industries, the quality and durability of piping systems are of utmost importance. As a high-performance material with widespread applications, ASTM A672 steel pipes are indispensable due to their high strength, corrosion resistance, and excellent weldability. Whether in oil and gas transportation, cross-border pipeline systems, or cooling systems in the power industry, ASTM A672 steel pipes have proven their exceptional adaptability and reliability. In this article, we will explore the applications and advantages of ASTM A672… In the steel pipe industry, ASTM A671 and ASTM A672 are two widely used standards, commonly applied in oil and gas transmission, chemical pipelines, water supply systems, and other industrial applications. While these two types of steel pipes share many similarities, they also have significant differences in performance requirements, manufacturing processes, and areas of application. Understanding the characteristics of both and their respective usage scenarios is crucial for engineers and procurement professionals when selecting the appropriate materials. This article will…

In the steel pipe industry, ASTM A671 and ASTM A672 are two widely used standards, commonly applied in oil and gas transmission, chemical pipelines, water supply systems, and other industrial applications. While these two types of steel pipes share many similarities, they also have significant differences in performance requirements, manufacturing processes, and areas of application. Understanding the characteristics of both and their respective usage scenarios is crucial for engineers and procurement professionals when selecting the appropriate materials. This article will… In the global energy transportation and industrial infrastructure sectors, ASTM A671 steel pipes have become the preferred choice for many projects due to their exceptional pressure resistance, excellent corrosion resistance, and wide range of applications. As a leading ERW/LSAW steel pipe manufacturer in China, Hebei Longma Steel Pipe Manufacturing Co., Ltd. (LONGMA) leverages advanced production technology and stringent quality control to supply high-quality ASTM A671 steel pipes, meeting the demanding requirements of oil and gas transportation, cross-border energy pipelines, and…

In the global energy transportation and industrial infrastructure sectors, ASTM A671 steel pipes have become the preferred choice for many projects due to their exceptional pressure resistance, excellent corrosion resistance, and wide range of applications. As a leading ERW/LSAW steel pipe manufacturer in China, Hebei Longma Steel Pipe Manufacturing Co., Ltd. (LONGMA) leverages advanced production technology and stringent quality control to supply high-quality ASTM A671 steel pipes, meeting the demanding requirements of oil and gas transportation, cross-border energy pipelines, and… ASTM A672 steel pipes are widely used in industries such as oil and gas transmission and water treatment, making it crucial to ensure their quality meets international standards. In the previous article, we discussed the standard specifications and applications of ASTM A672 steel pipes. In this article, we will focus on the quality control measures and inspection methods during production, ensuring that every pipe meets international standards and satisfies customer requirements! Overview of ASTM A672 Steel Pipes ASTM A672 steel…

ASTM A672 steel pipes are widely used in industries such as oil and gas transmission and water treatment, making it crucial to ensure their quality meets international standards. In the previous article, we discussed the standard specifications and applications of ASTM A672 steel pipes. In this article, we will focus on the quality control measures and inspection methods during production, ensuring that every pipe meets international standards and satisfies customer requirements! Overview of ASTM A672 Steel Pipes ASTM A672 steel… How can pipeline systems ensure long-term stability in oil and gas transportation? Which type of pipe can withstand harsh environments and high-pressure conditions while offering corrosion resistance, mechanical strength, and safety? As global energy infrastructure continues to advance, why has ASTM A672 steel pipe become the industry’s top choice? As a professional steel pipe manufacturer, Hebei Longma Steel Pipe Manufacturing Co., Ltd. (LONGMA) has over 20 years of experience, providing high-quality, corrosion-resistant pipes to support the safety and efficiency of…

How can pipeline systems ensure long-term stability in oil and gas transportation? Which type of pipe can withstand harsh environments and high-pressure conditions while offering corrosion resistance, mechanical strength, and safety? As global energy infrastructure continues to advance, why has ASTM A672 steel pipe become the industry’s top choice? As a professional steel pipe manufacturer, Hebei Longma Steel Pipe Manufacturing Co., Ltd. (LONGMA) has over 20 years of experience, providing high-quality, corrosion-resistant pipes to support the safety and efficiency of… In today's global infrastructure and energy transportation sectors, the demand for steel pipes continues to rise, especially in critical industries such as oil, gas, and water treatment. Among various steel pipe standards, ASTM A671 steel pipes stand out for their exceptional performance and reliability, making them a key choice in the industry. Whether it's their corrosion resistance in extreme temperatures or strength in high-pressure environments, ASTM A671 steel pipes are engineered to meet stringent requirements. However, this reliability and quality…

In today's global infrastructure and energy transportation sectors, the demand for steel pipes continues to rise, especially in critical industries such as oil, gas, and water treatment. Among various steel pipe standards, ASTM A671 steel pipes stand out for their exceptional performance and reliability, making them a key choice in the industry. Whether it's their corrosion resistance in extreme temperatures or strength in high-pressure environments, ASTM A671 steel pipes are engineered to meet stringent requirements. However, this reliability and quality… As global energy demand continues to rise, the oil and gas industry faces unprecedented challenges and opportunities. A critical component of infrastructure within this sector is the steel pipe, where the quality and performance directly impact the safety and efficiency of oil and gas transportation. ASTM A671 steel pipes, with their exceptional corrosion resistance, strength, and reliability, have become an indispensable material in the oil and gas industry. Whether used in extreme environments or subjected to the rigors of long-distance…

As global energy demand continues to rise, the oil and gas industry faces unprecedented challenges and opportunities. A critical component of infrastructure within this sector is the steel pipe, where the quality and performance directly impact the safety and efficiency of oil and gas transportation. ASTM A671 steel pipes, with their exceptional corrosion resistance, strength, and reliability, have become an indispensable material in the oil and gas industry. Whether used in extreme environments or subjected to the rigors of long-distance… With the global construction industry continuing to grow amidst increasing competition, material selection and cost control have become key factors for the success of any project. In the current economic climate, construction companies and engineers face the dual challenges of fluctuating raw material prices and increasingly stringent environmental regulations. Finding ways to maintain building quality while reducing costs and improving construction efficiency has become a pressing issue. Against this backdrop, ASTM A53 steel pipes have emerged as a popular choice…

With the global construction industry continuing to grow amidst increasing competition, material selection and cost control have become key factors for the success of any project. In the current economic climate, construction companies and engineers face the dual challenges of fluctuating raw material prices and increasingly stringent environmental regulations. Finding ways to maintain building quality while reducing costs and improving construction efficiency has become a pressing issue. Against this backdrop, ASTM A53 steel pipes have emerged as a popular choice…