Energy, the lifeblood of modern society, relies heavily on safe and efficient transportation. In this energy artery, API 5L steel pipes play an indispensable role. From vast deserts to frozen polar regions, from offshore oil and gas fields to underground urban pipelines, API 5L steel pipes, with their excellent performance and diverse grades, form the steel backbone of global energy transportation. However, faced with the wide variety of API 5L steel pipe grades, selecting the appropriate pipe to ensure safe and reliable operation in specific application scenarios has become a significant challenge for engineers. This article will delve into the performance characteristics of different grades of API 5L steel pipes and, combined with practical application scenarios, unveil the secrets of API 5L steel pipe selection, contributing to the safety and efficiency of energy transportation!

Introduction to Different Grades of API 5L Steel Pipes

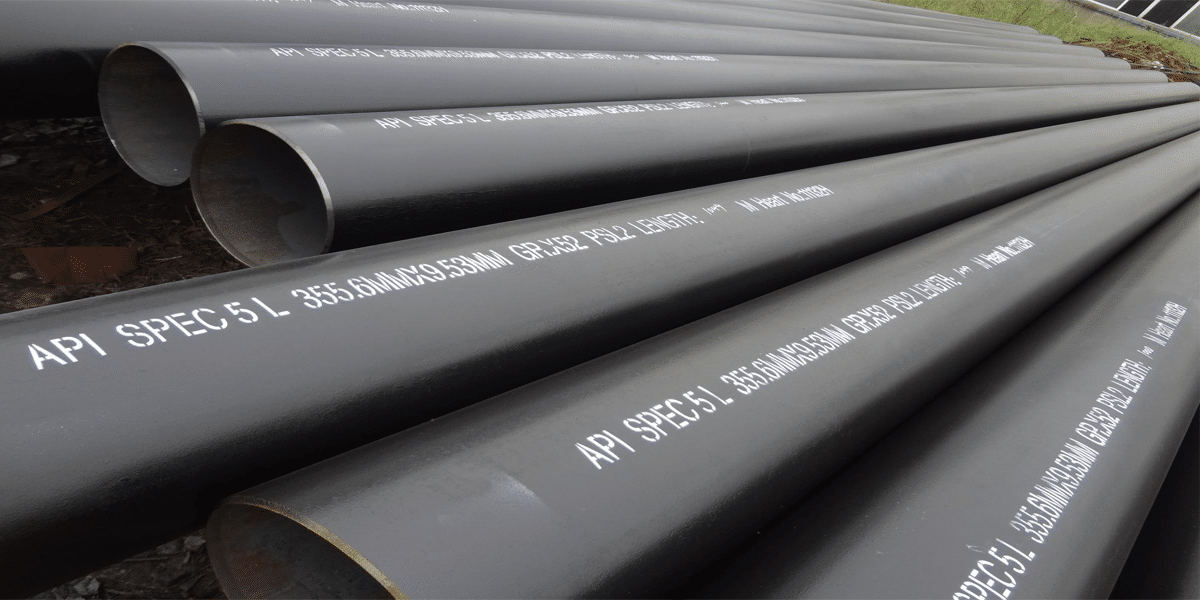

API 5L is a standard for line pipes established by the American Petroleum Institute (API), widely used for the transportation of oil, natural gas, and other energy resources. API 5L steel pipes are divided into multiple grades based on their chemical composition, mechanical properties, and manufacturing processes. Among these, API 5L X42, API 5L X52, and API 5L X60 are common grades suitable for different pressure levels and working conditions. Below is a detailed introduction to these three grades:

1. API 5L X42 Steel Pipe

Features:

Strength Grade: X42 indicates a minimum yield strength of 42,000 psi (approximately 290 MPa).

Chemical Composition: Low carbon content and moderate manganese content, providing good weldability and toughness.

Manufacturing Process: Typically produced through hot rolling or cold drawing, available as seamless or welded pipes.

Applications:

Low-pressure oil and gas transportation pipelines

Urban natural gas distribution networks

General industrial pipelines

Advantages:

Low cost, suitable for applications with lower strength requirements.

Excellent weldability, facilitating on-site installation and maintenance.

2. API 5L X52 Steel Pipe

Features:

Strength Grade: X52 indicates a minimum yield strength of 52,000 psi (approximately 360 MPa).

Chemical Composition: Slightly higher carbon and manganese content than X42, with possible addition of micro-alloying elements (e.g., niobium, vanadium) to enhance strength.

Manufacturing Process: Produced through hot rolling, cold drawing, or high-frequency resistance welding (HFW).

Applications:

Medium-pressure oil and gas transportation pipelines

Long-distance natural gas transmission pipelines

Offshore platform pipelines

Advantages:

Higher strength than X42, suitable for higher-pressure transportation environments.

Good corrosion resistance and low-temperature toughness.

3. API 5L X60 Steel Pipe

Features:

Strength Grade: X60 indicates a minimum yield strength of 60,000 psi (approximately 414 MPa).

Chemical Composition: Further increased carbon and manganese content, with additional alloying elements (e.g., niobium, vanadium, titanium) to enhance strength and toughness.

Manufacturing Process: Typically produced through thermomechanical controlled processing (TMCP) or quenching and tempering.

Applications:

High-pressure oil and gas transportation pipelines

Deep-sea oil and gas field development

Pipeline projects in polar or low-temperature environments

Advantages:

High strength, suitable for high-pressure and harsh environments.

Excellent low-temperature toughness and crack propagation resistance.

How to Choose the Right API 5L Steel Pipe Grade Based on Application Scenarios?

API 5L steel pipes are widely used for the transportation of oil, natural gas, and other energy resources. Different grades of steel pipes (e.g., X42, X52, X60) have varying levels of strength, toughness, and corrosion resistance. Selecting the appropriate API 5L steel pipe grade requires a comprehensive consideration of the specific requirements of the application scenario, including operating pressure, environmental conditions, transported medium, and cost. Below are detailed selection recommendations:

1. Selection Based on Operating Pressure

Operating pressure is a critical factor in choosing the API 5L steel pipe grade. Different grades have different minimum yield strengths, making them suitable for different pressure ranges.

Low-Pressure Scenarios (< 7 MPa):

Recommended Grade: API 5L X42

Reason: API 5L X42 pipes have a minimum yield strength of 290 MPa and are cost-effective, making them suitable for low-pressure oil and gas transportation and urban natural gas networks.

Application Examples: Urban natural gas distribution pipelines, low-pressure water pipelines.

Medium-Pressure Scenarios (7–15 MPa):

Recommended Grade: API 5L X52

Reason: API 5L X52 pipes have a minimum yield strength of 360 MPa, offering higher strength and good toughness, making them ideal for medium-pressure, long-distance transportation.

Application Examples: Long-distance natural gas transmission pipelines, medium-pressure oil pipelines.

High-Pressure Scenarios (> 15 MPa):

Recommended Grade: API 5L X60 or higher grades (e.g., X70, X80)

Reason: API 5L X60 pipes have a minimum yield strength of 414 MPa, providing excellent strength and pressure resistance, making them suitable for high-pressure transportation.

Application Examples: High-pressure natural gas transmission pipelines, deep-sea oil and gas field development.

2. Selection Based on Environmental Conditions

Environmental conditions (e.g., temperature, corrosiveness, geological factors) significantly influence the choice of steel pipes.

Normal Temperature Environments:

Recommended Grade: API 5L X42 or API 5L X52

Reason: In normal temperature environments, the requirement for low-temperature toughness is lower, and API 5L X42 and API 5L X52 pipes can meet the needs.

Application Examples: Standard onshore oil and gas transportation pipelines.

Low-Temperature Environments (e.g., Polar or High-Altitude Regions):

Recommended Grade: API 5L X60 or higher grades

Reason: API 5L X60 pipes have excellent low-temperature toughness, maintaining high strength and crack resistance in low-temperature environments.

Application Examples: Polar oil and gas transportation pipelines, high-altitude natural gas pipelines.

Corrosive Environments (e.g., Marine or Acidic Media):

Recommended Grade: API 5L X52 or API 5L X60 with anti-corrosion coatings or linings

Reason: API 5L X52 and API 5L X60 pipes can be enhanced with alloying elements to improve corrosion resistance, and additional anti-corrosion measures can extend their service life.

Application Examples: Offshore platform pipelines, acidic oil and gas field transportation pipelines.

3. Selection Based on Budget

Cost is an important factor to consider when choosing the API 5L steel pipe grade. Prices vary significantly between grades, and the selection should align with the project budget.

Low-Cost Projects:

Recommended Grade: API 5L X42

Reason: API 5L X42 pipes are the most cost-effective, suitable for projects with limited budgets.

Application Examples: Low-pressure urban natural gas networks, general industrial pipelines.

Medium-Cost Projects:

Recommended Grade: API 5L X52

Reason: API 5L X52 pipes offer a good balance of cost and performance, making them ideal for medium-pressure and medium-to-long-distance transportation projects.

Application Examples: Medium-pressure oil and natural gas transportation pipelines.

High-Cost Projects:

Recommended Grade: API 5L X60 or higher grades

Reason: API 5L X60 pipes are more expensive but offer superior performance, making them suitable for high-pressure and harsh environments.

Application Examples: High-pressure natural gas transmission pipelines, deep-sea oil and gas field development.

Comparison of API 5L Steel Pipe Grades and Their Properties

API 5L steel pipes are widely used in the oil and gas transportation industry, and different grades (e.g., X42, X52, X60, etc.) vary significantly in terms of chemical composition, mechanical properties, and applicable scenarios. Below is a comparison of the properties of common API 5L steel pipe grades (X42, X52, X60, X70, X80):

1. Mechanical Properties Comparison

The primary mechanical properties of API 5L steel pipes include yield strength, tensile strength, and elongation. As the grade increases, the strength and toughness of the pipes improve significantly.

API 5L X42: 290 Minimum Yield Strength (MPa). 415 Minimum Tensile Strength (MPa). ≥ 21 Elongation (%)

API 5L X52: 360 Minimum Yield Strength (MPa). 460Minimum Tensile Strength (MPa). ≥ 20 Elongation (%)

API 5L X60: 414 Minimum Yield Strength (MPa). 517 Minimum Tensile Strength (MPa). ≥ 18 Elongation (%)

API 5L X70: 483 Minimum Yield Strength (MPa). 565 Minimum Tensile Strength (MPa). ≥ 17 Elongation (%)

API 5L X80: 552 Minimum Yield Strength (MPa). 621 Minimum Tensile Strength (MPa). ≥ 16 Elongation (%)

2. Applicable Scenarios Comparison

Different grades of API 5L steel pipes are suitable for different pressure levels, environments, and transported media.

API 5L X42: Low-pressure oil and gas transportation, urban natural gas networks, general industrial pipelines

API 5L X52: Medium-pressure oil and gas transportation, long-distance natural gas pipelines, offshore platform pipelines

API 5L X60: High-pressure oil and gas transportation, deep-sea oil and gas field development, polar or low-temperature pipelines

API 5L X70: Ultra-high-pressure natural gas transportation, long-distance high-pressure pipelines, complex geological conditions

API 5L X80: Extreme-high-pressure oil and gas transportation, deep-sea or polar harsh environments, high-strength requirements

3. Manufacturing Process Comparison

Different grades of API 5L steel pipes also differ in their manufacturing processes, with higher grades typically requiring more complex processes to enhance performance.

API 5L X42: Hot rolling, cold drawing, high-frequency resistance welding (HFW)

API 5L X52: Hot rolling, cold drawing, high-frequency resistance welding (HFW)

API 5L X60: Thermomechanical controlled processing (TMCP), quenching and tempering

API 5L X70: Thermomechanical controlled processing (TMCP), quenching and tempering, microalloying

API 5L X80: Thermomechanical controlled processing (TMCP), quenching and tempering, advanced microalloying

4. Cost Comparison

API 5L X42: Low cost. Low alloy content, simple manufacturing process

API 5L X52: Medium cost. Moderate alloy content, relatively complex manufacturing process

API 5L X60: High cost. Higher alloy content, complex manufacturing process (e.g., TMCP)

API 5L X70: Very High cost. High alloy content, complex manufacturing process, and strict quality control

API 5L X80: Extremely High cost. Very high alloy content, advanced manufacturing process, and strict quality control

Quality Control and Inspection of API 5L Steel Pipes

API 5L steel pipes, as critical materials for oil and gas transportation, directly impact the safety and efficiency of energy delivery. To ensure the high quality of API 5L steel pipes, comprehensive management is required, covering quality control during production, inspection and certification standards, and long-term operational reliability. Below is a detailed analysis:

1. Quality Control During Production

Quality control during production is the foundation for ensuring the performance of API 5L steel pipes, encompassing raw material selection, manufacturing processes, and finished product inspection.

1.1 Raw Material Selection

Chemical Composition Control: The chemical composition of the steel pipes (e.g., carbon, manganese, silicon, sulfur, phosphorus) must comply with API 5L standards to ensure strength, toughness, and weldability.

Raw Material Inspection: Strict chemical composition analysis and mechanical property testing of steel plates or billets are conducted to ensure compliance with standards.

1.2 Manufacturing Process Control

Hot Rolling and Cold Drawing Processes: Temperature, deformation rate, and cooling speed must be strictly controlled during hot rolling or cold drawing to ensure the mechanical properties and microstructure of the pipes meet requirements.

Welding Process: For welded pipes (e.g., high-frequency resistance welding (HFW) or submerged arc welding (SAW)), welding parameters must be optimized to ensure weld quality and avoid defects such as porosity and slag inclusion.

Heat Treatment Process: For high-grade steel pipes (e.g., X60, X70), thermomechanical controlled processing (TMCP) or quenching and tempering processes are used to enhance strength and toughness.

1.3 Finished Product Inspection

Dimensional and Visual Inspection: The diameter, wall thickness, length, and surface quality of the pipes are inspected to ensure compliance with standards.

Non-Destructive Testing (NDT): Methods such as ultrasonic testing (UT), radiographic testing (RT), and magnetic particle testing (MT) are used to detect internal defects like cracks and porosity.

2. Inspection and Certification Standards

Inspection and certification standards are critical for ensuring the quality of API 5L steel pipes, covering product specification levels (PSL), inspection methods, and third-party certification.

2.1 Product Specification Levels (PSL)

PSL1: Suitable for general-purpose steel pipes with relatively lower inspection requirements, including chemical composition, mechanical properties, and dimensional checks.

PSL2: Suitable for high-demand steel pipes with stricter inspection requirements, including Charpy impact testing, hardness testing, and NDT.

2.2 Inspection Methods

Chemical Composition Analysis: Equipment such as spectrometers is used to analyze the chemical composition of the pipes.

Mechanical Property Testing: Includes tensile testing, impact testing, and hardness testing to evaluate the strength, toughness, and hardness of the pipes.

Non-Destructive Testing (NDT): Methods such as UT, RT, and MT are used to detect internal defects in the pipes.

Hydrostatic Testing: Hydrostatic pressure tests are conducted to ensure the pipes can withstand specified pressures.

2.3 Third-Party Certification

API Certification: API 5L steel pipe manufacturers must obtain API certification to ensure their products comply with API standards.

ISO Certification: Some manufacturers also obtain ISO 9001 quality management system certification to further enhance quality management.

3. Long-Term Operational Reliability

The long-term operational reliability of API 5L steel pipes is crucial for ensuring the safety of energy transportation, involving anti-corrosion measures, regular inspections, and maintenance.

3.1 Anti-Corrosion Measures

Coating Protection: External surfaces of the pipes are coated with epoxy resin, polyethylene, or other anti-corrosion coatings to prevent soil and water corrosion.

Cathodic Protection: Sacrificial anodes or impressed current cathodic protection systems are used to prevent electrochemical corrosion.

Internal Lining: For pipes transporting corrosive media (e.g., sour oil and gas), internal linings (e.g., fiberglass) can be applied.

3.2 Regular Inspection

Online Monitoring: IoT technology is used to monitor pipeline pressure, temperature, and corrosion status in real-time, identifying potential issues promptly.

Periodic Inspections: Regular inspections are conducted to check for coating damage, corrosion, and deformation.

Smart Inspection: Smart inspection devices (e.g., pipeline robots) are used for detailed internal inspections to assess pipeline health.

3.3 Maintenance and Repair

Coating Repair: Damaged anti-corrosion coatings are repaired promptly to prevent corrosion spread.

Defect Repair: Detected defects such as cracks and corrosion pits are repaired using methods like welding or reinforcement.

Replacement and Upgrades: Severely aged pipelines are replaced or upgraded with high-performance steel pipes to ensure transportation safety.

Market Trends and Future Development of API 5L Steel Pipes

API 5L steel pipes, as a core material for oil and gas transportation, are closely tied to the global energy industry. In recent years, with the growth of energy demand, increasing environmental requirements, and technological advancements, the API 5L steel pipe market has shown new development trends. Below is an analysis of the current market status, trends, and future development:

1. Current Market Status

Global Demand Growth

Oil and Gas Resource Development: With the continuous growth of global energy demand, especially the increasing adoption of natural gas as a clean energy source, the demand for API 5L steel pipes has been steadily rising.

Emerging Market Drivers: Oil and gas resource development and infrastructure construction in the Asia-Pacific region (e.g., China, India) and the Middle East have driven the expansion of the API 5L steel pipe market.

Aging Pipeline Replacement: The aging oil and gas pipeline systems in developed regions such as Europe and North America have created new growth opportunities for pipeline replacement and upgrades.

Major Production and Consumption Regions

Production Regions: China, the United States, Japan, Germany, and India are the leading producers of API 5L steel pipes globally.

Consumption Regions: North America, Asia-Pacific, and the Middle East are the primary consumers of API 5L steel pipes, with the Asia-Pacific region experiencing the fastest demand growth.

2. Market Trends

Increasing Demand for High-Grade Steel Pipes

High-Pressure Transportation Needs: The development of deep-sea oil and gas fields and polar resources has increased the demand for high-pressure transportation pipelines, driving the need for high-grade API 5L steel pipes (e.g., X70, X80, X100).

Long-Distance Pipeline Projects: Long-distance natural gas transmission pipeline projects (e.g., cross-country pipelines) require steel pipes with higher strength and corrosion resistance, further promoting the application of high-grade steel pipes.

Environmental Protection and Sustainable Development

Green Manufacturing: The steel industry is gradually transitioning to green manufacturing, with increasing adoption of energy-saving and environmentally friendly technologies in the production of API 5L steel pipes.

Pipeline Leakage Prevention: Stricter environmental regulations have prompted oil and gas companies to prioritize pipeline safety and leakage prevention, boosting the demand for high-performance steel pipes.

Technological Innovation and Intelligence

Advanced Manufacturing Processes: The application of advanced technologies such as thermomechanical controlled processing (TMCP) and quenching and tempering has improved the performance and quality of API 5L steel pipes.

Intelligent Pipeline Monitoring: The use of IoT and big data technologies enables real-time monitoring and intelligent maintenance of pipeline operations, extending the service life of steel pipes.

3. Future Development

Deep-Sea and Polar Resource Development

Deep-Sea Oil and Gas Fields: As onshore oil and gas resources gradually deplete, the development of deep-sea oil and gas fields will become a key direction for the energy industry, significantly increasing the demand for API 5L steel pipes in deep-sea environments.

Polar Resource Development: Oil and gas resource development in polar regions requires steel pipes with low-temperature resistance and high strength, driving further innovation in API 5L steel pipe technology.

New Energy and Hydrogen Transportation

Hydrogen Economy: With the promotion of hydrogen as a clean energy source, API 5L steel pipes have significant potential in hydrogen transportation pipelines. Special-grade steel pipes suitable for hydrogen transportation may need to be developed in the future.

Carbon Capture and Storage (CCS): The application of API 5L steel pipes in carbon dioxide transportation pipelines will also become an important growth area for the market.

Globalization and Regional Cooperation

Cross-Country Pipeline Projects: Strengthened global energy cooperation will drive the development of cross-country pipeline projects (e.g., the Belt and Road Energy Corridor), promoting the globalization of the API 5L steel pipe market.

Regional Supply Chain Integration: To reduce costs and improve efficiency, the production and supply chain of API 5L steel pipes will gradually shift toward regionalization and localization.

4. Challenges and Opportunities

Challenges

Raw Material Price Fluctuations: Fluctuations in steel raw material prices may impact the production costs and market prices of API 5L steel pipes.

Environmental Pressure: Strict environmental regulations may increase compliance costs for steel pipe manufacturers.

Technical Barriers: The development and production of high-grade steel pipes require advanced technologies and equipment, posing higher demands on companies’ technical capabilities.

Opportunities

Emerging Market Demand: The rapid development of the Asia-Pacific and Middle East regions provides significant growth potential for the API 5L steel pipe market.

Technological Innovation: The application of new materials and processes will enhance the performance of API 5L steel pipes, meeting more complex application requirements.

Energy Transition: The global energy transition (e.g., the development of natural gas and hydrogen) presents new opportunities for the API 5L steel pipe market.

API 5L steel pipes, as a core material for energy transportation, play an indispensable role in the global energy industry. With the growth of energy demand, advancements in technology, and increasing environmental requirements, the API 5L steel pipe market is embracing new development opportunities. Whether it’s the development of deep-sea oil and gas fields or the rise of the hydrogen economy, API 5L steel pipes will continue to play a vital role in the future energy landscape!

We hope this article has provided you with valuable insights and a better understanding of the market trends and future development of API 5L steel pipes. If you found this article helpful, please give it a thumbs up and share it with others who might benefit from this information. Let’s spread awareness about the latest developments in this important field. Thank you for reading and for your support!