Your EN10219-1 Cold Finished Structural Hollow Section manufacturer in China

LONGMA produces and stocks a full range of EN10219-1 Cold Finished Structural Hollow Section. It can be welded or seamless heavy wall steel pipes for machine work. We export tens of thousands of tons of such steel pipes every year to EU, UK, Thailand, Singapore, Austrilia, New Zealand, Iran, Peru, Chile. If you want to import high quality EN10219 S235/S355 steel pipes, come to LONGMA.

- Grades: S235/S355 JRH/J0H/J2H

- Outer Diameter: 4″-56″

- Thickness: 0.237″-5.90″

- Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, FBE, HDG(Hot Dipped Galvanized)

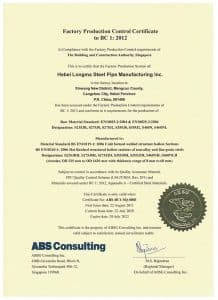

Our Certifications

Our EN10219-1 Cold Finished Structural Hollow Section Product List

Longma produce & export EN10219 S235JRH/S355JRH/S355J2H Cold Finished Structural Hollow Section since 2003.

EN10219 S235JR Steel Pipe

EN10219 S355JR Steel Pipe

EN10219 S355J0H Steel Pipe

EN10219 S355J2H Hollow Section

EN10219 S355 Hollow Section

EN10219 S235 Hollow Section

EN10219 S355J2H LSAW Pipe

EN10219 S355JR CF Steel Pipe

EN10219 Structural Hollow Section

Longma produce & export EN10219 S235JRH/S355JRH/S355J2H Cold Finished Structural Hollow Section since 2003

- Longma produce & export EN10219 S235JRH/S355JRH/S355J2H Cold Finished Structural Hollow Section since 2003.

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

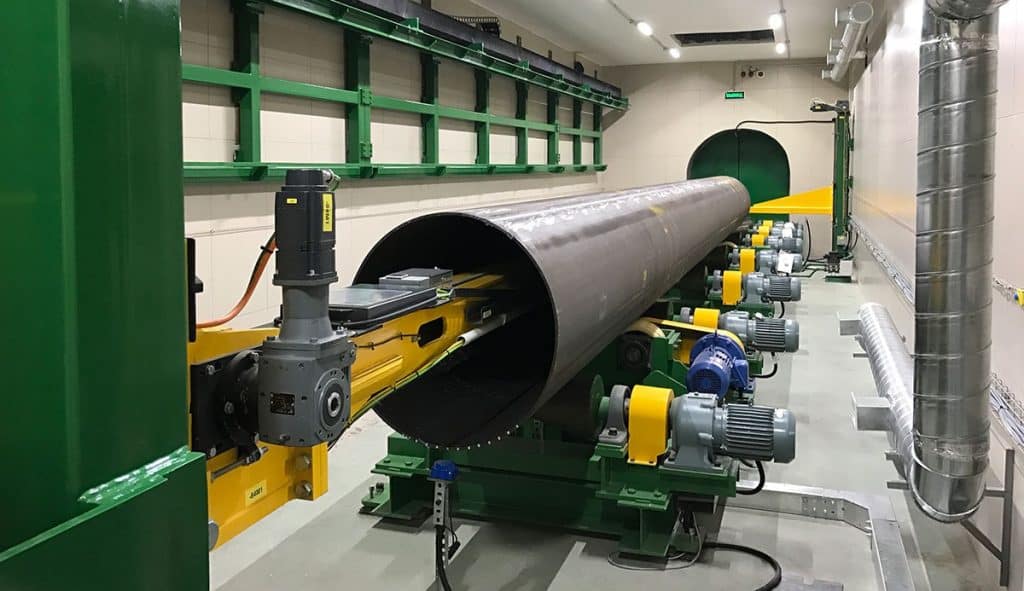

EN10219 Cold Finished Structural Hollow Section Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

X-Ray Testing

Ultrasonic Testing

Tack Welding

Plate Ultrasonic Testing

Pipe Forming

Pipe End Bevelling

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For EN10219 Cold Finished Structural Hollow Section

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For EN10219 Cold Finished Structural Hollow Section

Table A.1 — Chemical composition — Cast analysis for product thickness≤120 mm

| Steel grade | Type of deoxidation | % by mass, maximum | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Steel name | Steel number | C Specified thickness (mm) | Si | Mn | P | S | N b c | ||

| £ 40 | >40 £ 120 | ||||||||

| S235JRH | 1.0039 | FN | 0,17 | 0,20 | — | 1,40 | 0,040 | 0,040 | 0,009 |

| S275J0H | 1.0149 | FN | 0,20 | 0,22 | — | 1,50 | 0,035 | 0,035 | 0,009 |

| S275J2H | 1.0138 | FF | 0,20 | 0,22 | — | 1,50 | 0,030 | 0,030 | — |

| S355J0H | 1.0547 | FN | 0,22 | 0,22 | 0,55 | 1,60 | 0,035 | 0,035 | 0,009 |

| S355J2H | 1.0576 | FF | 0,22 | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| S355K2H | 1.0512 | FF | 0,22 | 0,22 | 0,55 | 1,60 | 0,030 | 0,030 | — |

| a The deoxidation methods are designated as follows: FN = Rimming steel not permitted FF = Fully killed steel containing nitrogen binding elements in amounts sufficient to bind available nitrogen (e.g. min. 0,020 % total Al, or 0,015 % soluble Al). b It is permissible to exceed the specified values provided that for each increase of 0,001 % N the P max. content is also reduced by 0,005 %. The N content of the cast analysis, however, shall not be more than 0,012 %. c The maximum value for nitrogen does not apply if the chemical composition shows a minimum total Al content of 0,020 % with a minimum Al/N ratio of 2:1, or if sufficient other N-binding elements are present. The N-binding elements shall be recorded in the Inspection Document. |

|||||||||

Table A.2 — Maximum carbon equivalent value (CEV) based on cast analysis a

| Steel grade | Maximum CEV in % for specified thicknesses in mm | ||||

|---|---|---|---|---|---|

| Steel name | Steel number | £ 16 | > 16 £ 40 |

> 40 £ 65 |

> 65 £ 120 |

| S235JRH | 1.0039 | 0,37 | 0,39 | 0,41 | 0,44 |

| S275J0H | 1.0149 | 0,41 | 0,43 | 0,45 | 0,48 |

| S275J2H | 1.0138 | 0,41 | 0,43 | 0,45 | 0,48 |

| S355J0H | 1.0547 | 0,45 | 0,47 | 0,50 | 0,53 |

| S355J2H | 1.0576 | 0,45 | 0,47 | 0,50 | 0,53 |

| S355K2H | 1.0512 | 0,45 | 0,47 | 0,50 | 0,53 |

| a See 6.5.2, Option 1.2. | |||||

Table A.3 — Mechanical properties of non-alloy structural steel hollow section

| Steel grade | Min. yield strength ReH MPa |

Tensile strength Rm MPa |

Min. elongation A a b % |

Minimum impact energy KV d J |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specified thickness mm |

Specified thickness mm |

Specified thickness mm |

At test temperature of |

||||||||||||||

| Steel name | Steel number | £16 | >16 £40 |

>40 £63 |

>63 £80 |

>80 £100 |

> 00 £120 |

£3 | >3 £100 |

>100 £120 |

£ 40 | >40 £63 |

>63 £100 |

>100 £120 |

-20°C | 0°C | 20°C |

| S235JRHc | 1.0039 | 235 | 225 | 215 | 215 | 215 | 195 | 360-510 | 360-510 | 350-500 | 26 | 25 | 24 | 22 | – | – | 27 |

| S275J0Hc | 1.0149 | 275 | 265 | 255 | 245 | 235 | 225 | 430-580 | 410-560 | 400-540 | 23 | 22 | 21 | 19 | – | 27 | – |

| S275J2H | 1.0138 | 27 | – | – | |||||||||||||

| S355J0Hc | 1.0547 | 355 | 345 | 335 | 325 | 315 | 295 | 510-680 | 470-630 | 450-600 | 22 | 21 | 20 | 18 | – | 27 | – |

| S355J2H | 1.0576 | 27 | – | – | |||||||||||||

| S355K2H | 1.0512 | 40 e | – | – | |||||||||||||

| a Longitudinal values. Transverse values are 2 % lower. b For thicknesses < 3 mm, see 9.2.2. c The impact properties are verified only when Option 1.3 is specified. d For impact properties for reduced section test pieces see 6.6.2. e This value corresponds to 27J at –30 °C (see EN 1993-1-1). |

|||||||||||||||||

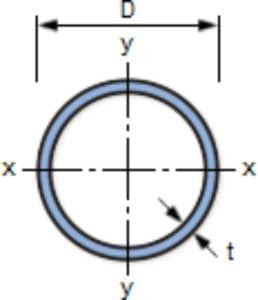

| Designation | Property | Tolerance | ||

|---|---|---|---|---|

|

Outside diameter D | ±1.0% with a min of ±0.5 mm and a max of ±10 mm | ||

| Thickness t | Welded | –10% | ||

| Seamless | –10% but between 10% and 12.5% may occur over not more than 25% of the circumference | |||

| Note: Positive deviation is limited by mass tolerance | ||||

| Measured at the centre of the length | Straightness (x or y direction) | 0.20% L | ||

| Mass per unit length | Mass of section | Welded | ±6.0% on individual lengths | |

| Seamless | +8.0% –6% on individual lengths | |||

| Standard | Length L | +150 mm | –0 mm | |

The applications of EN 10210 S235JRH/S355JRH/S355J0H/S355J2H circular pipes are numerous.

- Industries requiring high-performance tubing solutions, such as:construction, oil and gas, automobile, etc.

- Building structures, bridge structures, and support columns utilize these pipes.

- Piling oil rigs, underwater pipelines, and offshore platforms.

- Mining industries utilize these pipes for the transportation of underground water, coal, and other minerals.

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. What is EN 10210?

EN 10210 is the standard for hot finished hollow sections, and covers a number of subtly different products, manufactured in different ways and with different properties. Tata Steel’s Celsius range, for example, is designated within the standard as S355NH because it is full-body normalised.

2. What is the difference between EN10210 and EN10219?

In EN 10210, the grade refers to the steel in the finished hollow section; In EN 10219, the grade refers to the steel feedstock used for cold-forming of the hollow section, so the metallurgy will be modified in the cold forming process.

3. What is En 10210 steel grade?

EN 10210 Grade S355J2H Pipe and Tube are low-cost Low Carbon Steel Pipes and Tubes with maximum 0.22% of carbon content with combination of maximum 1.6% of manganese easy to form and shape. The pipes are manufactured as per EN Specification and commercially known as carbon steel pipes or mild steel pipes.

4. Is EN10210 hot finished?

EN 10210 is the standard for hot finished hollow sections, and covers a number of subtly different products, manufactured in different ways and with different properties.

5. What is the yield strength of EN 10210?

The material has silicon, manganese, phosphorus and sulfur in the composition. The combination of elements in the EN 10210 S355J2H Material provides it with 355MPa minimum yield strength and 630MPa minimum tensile strength.

6. What is standard EN 10210-2

This document specifies tolerances for hot finished circular, square, rectangular and elliptical structural hollow sections, manufactured in wall thicknesses up to 120 mm, in the following size ranges: – Circular: Outside diameters up to 2 500 mm; – Square: Outside dimensions up to 800 mm × 800 mm; – Rectangular: …

Featured Case For EN10219 Cold Finished Structural Hollow Section

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.