Your FBE, 2PP, 3LPE/3PE coating steel pipes manufacturer In China

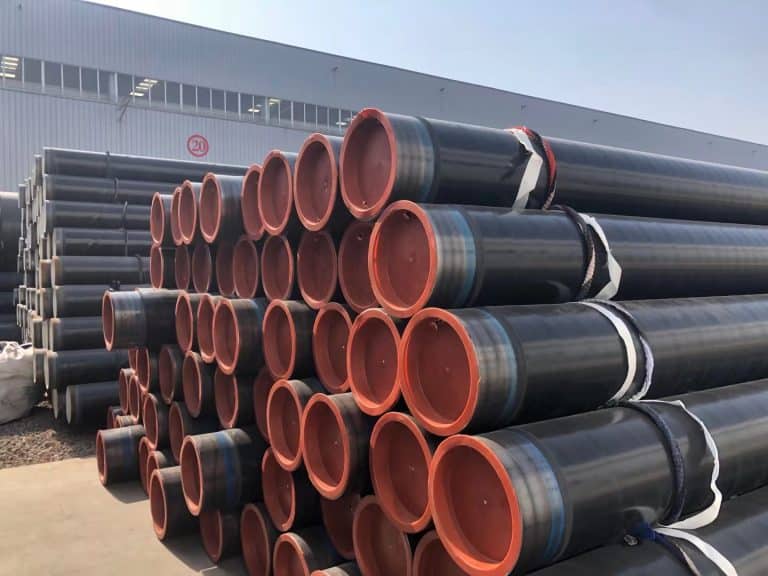

LONGMA produce and export large quantity FBE, 2PP, 3LPE/3PE coating steel pipes/anti-corrosion pipes.

External & internal coatings. Anti-corrosion coatings act as a barrier layer that prohibits or slows down the formation of corrosion on the underlying metal surface of the carbon steel pipe. By preventing external corrosion with the use of either single or multi-layer anti-corrosion coatings, it ensures precious natural resources and other products reach their destination safely and efficiently.

- Pipe Standard: API 5L, ASTM A106, ASTM A53, EN10210, AS/NZS1163

- Coating standard: DIN 30670, DIN 30678, CSA Z245.20, EN10339, ISO 21809-1, AWWA C210, C213

- Out Diameter: 60.3-1422mm(2″-56″)

- Wall Thickness: 6.02-50.8mm(0.237″ – 2″)

- Length: 3-18 meters

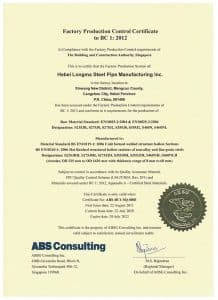

Our Certifications

Our FBE, 2PP, 3LPE/3PE Coating Steel Pipes Product List

Longma produce & export EN10210/EN10219 S235JRH/S355JRH/S355J2H Hot Finished Structural Hollow Section since 2003.

Fusion bonded epoxy(FBE) coated pipe

2LPE Coating Pipe

DIN 30670 3LPE Coating Pipe

3LPE External & FBE Internal Anti-corrosion Pipes

DIN30678 3PP Anticorrosive Steel Pipe

3PE Reinforced Anti-corrosion Steel Pipe

About Longma

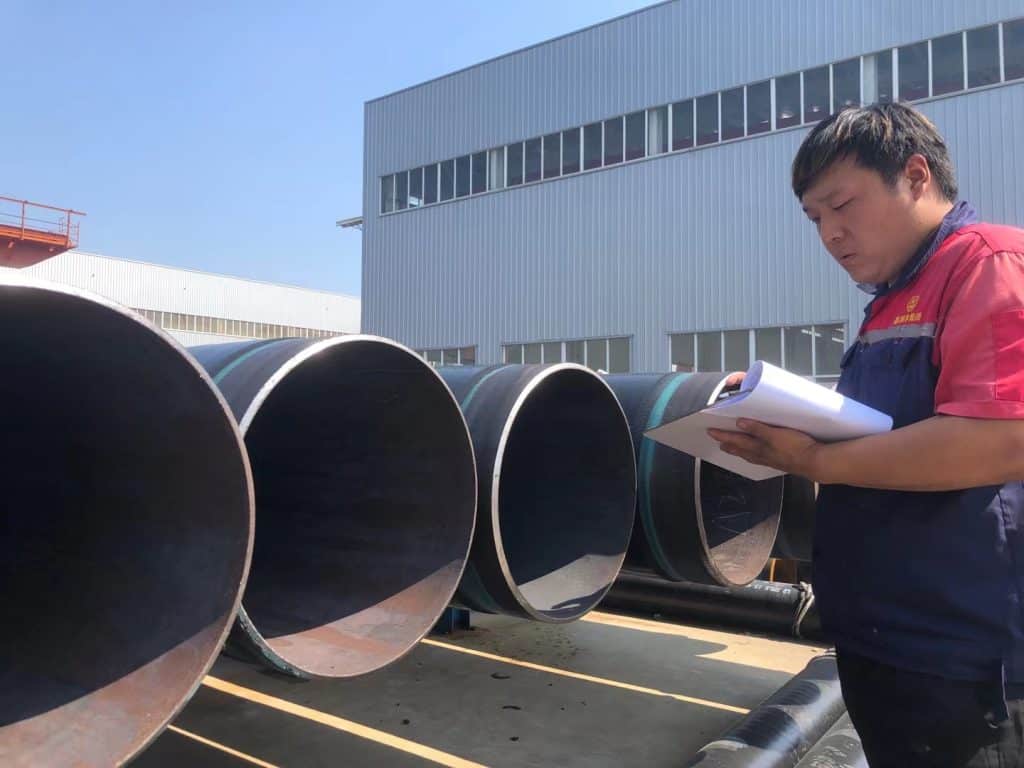

- Foundin 2003, specialized in produce ERW, LSAW, DSAW steel pipes with an annual output of 300,000 tons.

- Two factories, 200,000 square meters of plant.

- Advanced production equipment imported from Germany, 16 JCO production lines.

- More than 300 employees and more than 60 technicians provide efficient production operations and technical services.

- API 5L(No. 5L-0685, Expiration date: 16th,Nov,2024), ISO9001, ISO14001, ISO18001, FPC certificates.

- Exports high quality steel pipes to more than 60 countries around the world.

FBE, 2PP, 3LPE/3PE Coating Steel Pipes Production Line

Annual output of 300,000 tons of LSAW steel pipes, with out diameter Φ406mm- 1626mm (16″ – 64″), wall thickness 6.0mm- 75mm (1/4″ – 3″), length 18 meters max.

Coating Process

Cooling

Holiday Test

Package

Sand Blast

Size Inspection

Mechanical Expansion

Hydrostatic Pipe Testing

Our Advantages For FBE, 2PP, 3LPE/3PE Coating Steel Pipes

Complete Specifications

Good Quality

Fast Delivery

Quick Quotation

Accept Small Quantity Order

Complete Certificate

Technical Data For FBE, 2PP, 3LPE/3PE Coating Steel Pipes

Frequently Asked Questions

Here are some common questions and answers. If you still have questions, don’t hesitate to contact us.

1. What is the coating on pipe?

As a pipe coating, polyurethane is typically used as an interior lining because it reacts to light. It’s an excellent choice for potable water because it doesn’t contain any volatile organic compounds (VOCs) and is highly resistant to corrosion. Moreover, it’s thin and cures quickly.

2. What is the best coating for pipelines?

This is one of the best types of pipeline coating. Fusion bonded epoxies are single-component, heat-curable, thermosetting epoxy. FBEs apply to heating parts in the form of a powder (10-40 mils) that quickly gels from liquid to solid.

3. What grades are included in the A691 standard?

The standard ASTM A691 is included grade CM-65, CM-70, CM-75, CMSH-70,CMS-75, CMSH-80, 1/2 CR, 1 CR, 1 1/4 CR, 2 1/4 CR, 3CR, 5CR, 9CR, 91.

4. Why is pipe coating important?

Pipe coatings protect pipelines from corrosion-related defects. They are just one element of the total package operators employ to ensure their pipelines are well protected. Cathodic protection and integrity assessments are also used to prevent corrosion, and to detect any defects that may result from corrosion.

5. What is the most common pipeline coating?

Fusion bonded epoxy (FBE) is one of the most popular pipe coatings given its suitability for both internal and external use. FBE is impact, wear and chemical resistant. Therefore, it’s suitable for underwater and underground conditions ranging from -40 to +80 degrees.

6. What is the difference between pipe lining and pipe coating?

Pipelining is used on pipes that are in good condition. The lining is applied over the existing pipe and stops corrosion from occurring. However, if there’s damage to the pipes, you’ll need to replace them entirely. Pipe coating can be applied on any type—new or old, damaged or not.

Featured Case For FBE, 2PP, 3LPE/3PE Coating Steel Pipes

API 5L PSL2 X70M LSAW Pipe

- Size: 914.4*22.23*12000MM

- Country: Agentina

- Client say: This is not our first cooperation, Longma’s product quality and service has always been very good, which is the reason why we continue......

APL 5L PSL1 B LSAW Pipe

- Size: 813*10mm

- Country: Georgia

- Client say: The delivery time I asked for was very short, but they always finished on time. They have very strong organizational and coordination skills. ......

EN10210 S355J2H Hollow Section

- Size: 815mm*100mm

- Country: Poland

- Client say: The steel pipes I purchased are used for equipment manufacturing and special engineering, which have extremely strict requirements for product quality. The production......

ASTM A691 1-1/4Cr Cl22 EFW Steel Pipe

- Size: 508*20.62mm

- Country: Singapore

- Client say: Although our order quantity is not large, Longma has been very diligent to help us complete the production and provide relevant documents.

Request Free Quote

Get In Touch

How Can We Help?

Longma experienced engineers are here to guide you through every critical step in your project.

Please do not hesitate to contact us.