- 1. 1. Installation process flow of fire pipeline system

- 2. 2. Connection technology for firefighting pipes and fittings

- 3. 1) General connection accessories for fire pipes

- 4. 2) Trench (clamp) connection of fire pipes and fittings

- 5. 3) Screw connections in fire piping systems

- 6. 4) Welding or flange connection joints

- 7. 3. Steel pipes commonly used for firefighting piping:

A brief introduction to fire pipes and connecting accessories

Fire pipes and connecting accessories are mainly used to connect fire equipment, transport fire water, etc. It is also known as fire sprinkler pipes and fittings. Due to special requirements, there are special requirements for the thickness and materials of fire pipes and joints. According to regulations, fire pipes need to be sprayed with red paint, which is significantly different from other pipes. Because fire pipes are often in a stationary state, the requirements are stricter. Fire pipes and connecting fittings must have performance such as pressure resistance, corrosion resistance, and high temperature resistance.

Fire pipes can be divided into ductile iron pipes, copper pipes, stainless steel pipes, alloy pipes and composite pipes, and plastic pipes according to their materials.

1. Installation process flow of fire pipeline system

Installation preparation ->Main pipe installation ->Alarm valve installation ->Riser installation ->Spray layered circulation pipe, fire hydrant and branch pipe installation ->Water flow indicator, fire pump, high-level water tank, pump coupling installation ->Pipeline pressure testing ->Pipeline flushing ->Spray head branch pipe installation (system comprehensive pressure testing and flushing) ->Throttling device installation ->Alarm valve accessories, fire hydrant accessories, spray head installation ->System water testing

2. Connection technology for firefighting pipes and fittings

1) General connection accessories for fire pipes

When hot-dip galvanized steel pipes are used for the fire hydrant water supply system pipeline, welding is not allowed. If the fire protection pipeline uses materials without anti-corrosion treatment on the inner wall, welding connection can be used. But pipeline welding should comply with relevant requirements. The pipeline of the automatic sprinkler fire extinguishing system cannot be welded, and connection methods such as threads and flanges should be used.

In the fire hydrant water supply system, hot-dip galvanized steel pipes with a diameter greater than 100mm should be connected by flanges or grooves.

If the diameter of the pipeline is greater than 100 millimeters and there is no clear indication in the automatic sprinkler system, threaded connections cannot be used. Only require flange or groove connection points to be arranged at a certain distance on pipes with a diameter greater than 100 millimeters.

When the pipes of the fire hydrant water supply system and automatic sprinkler fire extinguishing system are connected with flanges, it is recommended to use threaded flanges. When welding flanges, secondary galvanizing should be carried out.

If it is necessary to change the diameter of the fire protection pipe section, connection fittings that meet the standards should be used.

2) Trench (clamp) connection of fire pipes and fittings

The groove connection (pipe joint) and the depth of the fire steel pipe groove should meet the requirements of groove type pipe joints. The maximum working pressure for groove pipe joints with a nominal diameter of DN250 and below is 2.5 MPa. The maximum working pressure for groove pipe joints with a nominal diameter of DN300 and above is 1.6 MPa.

Flexible joints can be used in vibration areas and buried fire pipelines, while rigid joints should be used in other areas. When using rigid joints, one flexible joint should be provided for every 4-5 rigid joints.

3) Screw connections in fire piping systems

For fire-resistant pipelines, hot-dip galvanized welded steel pipes or hot-dip galvanized seamless steel pipes with inner and outer wall diameters less than 100 mm can be connected with threads. When hot-dip galvanized ERW steel pipes are used in the system, malleable cast iron threaded fittings can be used. If hot-dip galvanized seamless steel pipes are used, forged steel threaded fittings can be used.

When the wall thickness of the steel pipe is less than δ< Sch30 (DN ≥ 200mm) or less δ< When Sch40 (DN<200mm), threaded connections shall not be used.

When the fire protection pipeline adopts a 55 ° cone pipe thread (Rc or R), the threaded interface can be sealed with polytetrafluoroethylene. When using 60 ° taper pipe threads (NPT) for pipelines, it is advisable to use sealant as a seal for the threaded interface. The sealing tape should be attached to the external thread.

Fire protection pipelines with a diameter less than DN50 shall not use threaded joints, and individual reducing joints shall be used at the pipe diameter reduction point.

4) Welding or flange connection joints

According to the connection method, flanges can be divided into flat welded flanges, welded flanges, and threaded flanges. The selection of flanges should comply with the standards for steel pipe flanges, steel butt welded seamless fittings, and PTFE coated gaskets for pipe flanges.

When hot-dip galvanized steel pipes are connected by flanges, threaded flanges should be selected. When the fire protection pipeline system uses fire pipes without anti-corrosion treatment on the inner wall, welding connections can be used.

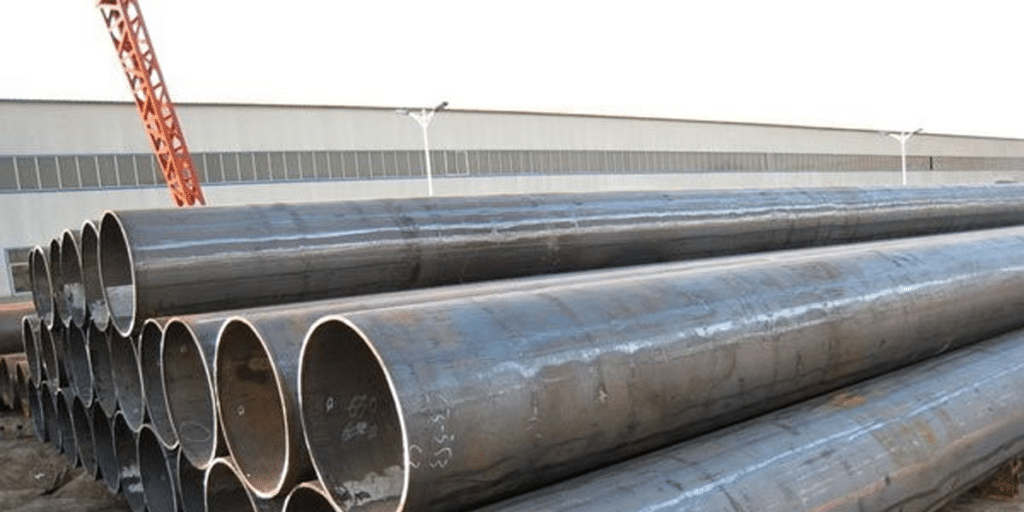

3. Steel pipes commonly used for firefighting piping:

1)ASTM A53 GRADE B: (keywords: ASTM A53 black steel pipes, ASTM A53 B hot dipped galvanized steel pipes)

ASTM A53 Grade B (A53B) is a commonly used steel pipe standard that is commonly used in many applications, including general purpose piping systems and fire protection piping systems. The following are applications of ASTM A53 Grade B steel pipe in fire protection piping:

*Piping for fire protection systems: ASTM A53 Grade B steel pipe is commonly used in piping for fire protection systems, including automatic sprinkler systems and other fire protection devices. These pipes are used to convey water or other extinguishing media to ensure a rapid response and adequate supply of extinguishing agent in the event of a fire.

*Corrosion resistance: ASTM A53 Grade B steel pipe can be hot dip galvanised to improve its corrosion resistance, which is particularly important for fire protection piping. Hot-dip galvanised steel pipe can resist corrosion in water and air, extending the life of the pipe and ensuring the reliability of the piping system in an emergency.

*Pressure Resistance: ASTM A53 Grade B steel pipe has good pressure resistance and is able to withstand certain pressures and shock loads. This characteristic makes it ideal for firefighting piping systems, capable of providing adequate water pressure and flow when needed. ASTM A53 Grade B steel pipe conforms to the ASTM International Standard, as well as other relevant safety and performance requirements for fire protection piping. During installation and use, it is important to ensure that the pipe complies with all applicable codes and standards to ensure the reliability and safety of the fire protection system.

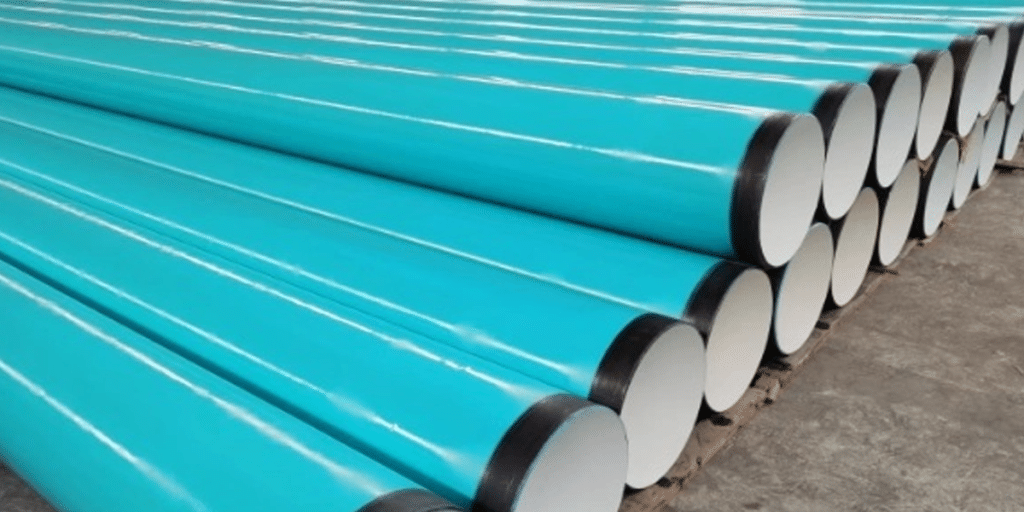

2)AS/NZS 1163: (keywords: AS NZS 1163 C250 Circular hollow section/C250 CHS black surface or bare surface)

In fire fighting pipework, AS/NZS 1163 steel pipe can also be applied, but its suitability needs to be determined on a case-by-case basis and according to local requirements. The following are some of the potential applications of AS/NZS 1163 steel pipe in fire fighting pipelines:

*Structural support: AS/NZS 1163 steel pipes can be used to build support structures for fire protection pipework systems, such as brackets and frames. These support structures need to have sufficient strength and stability to support the pipes and their accessories.

*Water conveyance pipes: In fire protection systems, AS/NZS 1163 steel pipes can be used to convey water, for example, from pumps to sprinkler heads. These pipes need to be pressure- and corrosion-resistant to ensure a continuous flow of water in an emergency.

*Sprinkler head support: In sprinkler systems, the pipes that support the sprinkler heads often need to meet specific standards, and AS/NZS 1163 steel pipe can be used to support and connect sprinkler heads to ensure their stability and reliability.

*Fittings and connections: In addition to the pipe itself, fittings and connections for AS/NZS 1163 steel pipe may also be used in fire protection pipework systems. These fittings and connections need to comply with the relevant standards and ensure the integrity and reliability of the pipework system.

LONGMA produce and export AS 1163 C250 CHS/ circular hollow sections, AS/NZS 1163 C250 steel pipes, ASTM A53 Grade B hot dipped galvanized steel pipes, A53 B black steel pipes, can be used as fire pipes/firefighting pipe/fire protection pipes, size from NPS2 to NPS 8, Sch10-XXS. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality AS NZS 1163 grade C250 with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.