- 1. Chemical Composition and Material Properties of AS 1163 C350L0 CHS

- 2. Structural Integrity and Load Capacity

- 3. Design flexibility and versatility

- 4. Weldability and fabrication considerations

- 5. Corrosion resistance and durability

- 6. Standards and code compliance

- 7. Case studies and real-world applications

The Application of AS 1163 C350L0 CHS in Structural Area

AS 1163 C350L0 CHS (Cold Formed Hollow Structural Sections) is a type of high strength steel widely used in structural applications. Its importance lies in its ability to provide superior load-bearing capacity while offering design flexibility and versatility. C350L0 CHS is known for its excellent mechanical properties, corrosion resistance and ease of fabrication.

Key properties and characteristics of C350L0 CHS include high yield strength, good ductility, and resistance to environmental factors. The purpose of this article is to evaluate the performance of C350L0 CHS in various structural applications, considering its material properties, structural integrity, design flexibility, weldability, corrosion resistance, and compliance with industry standards.

Chemical Composition and Material Properties of AS 1163 C350L0 CHS

AS 1163 C350L0 CHS has a carefully controlled chemical composition consisting primarily of iron with minor additions of carbon, manganese, silicon, and other alloying elements. This chemical composition contributes to the material’s exceptional mechanical properties, including a minimum yield strength of 350 MPa and good ductility.

The combination of high yield strength and ductility allows C350L0 CHS to withstand significant loads while maintaining structural integrity and resistance to deformation. These properties make C350L0 CHS an ideal material for structural applications where strength and toughness are paramount.

Structural Integrity and Load Capacity

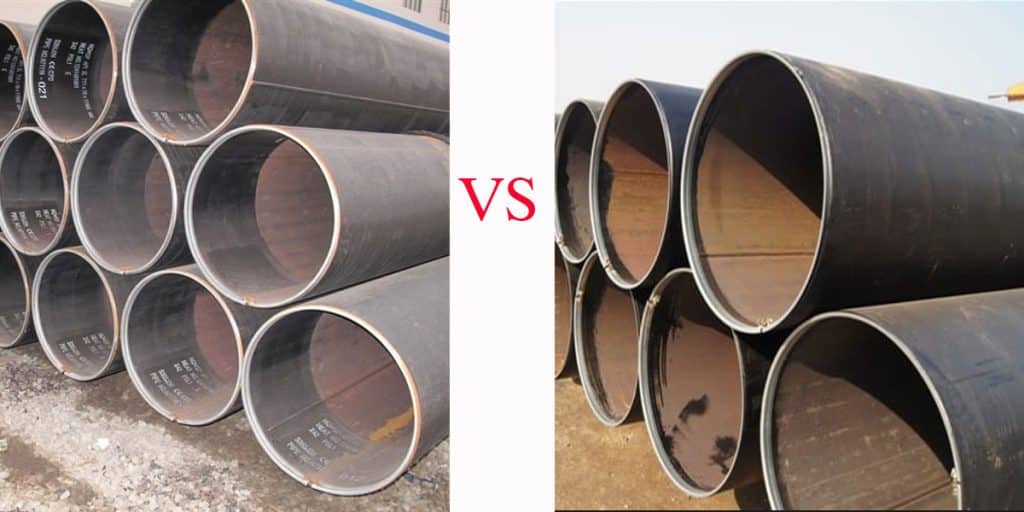

The structural integrity of AS 1163 C350L0 CHS is evaluated through various loading conditions such as flexure, compression and combined loading. C350L0 CHS has excellent load-bearing capacity and resistance to deformation, making it suitable for applications where high structural loads are expected.

The load capacity of C350L0 CHS is influenced by factors such as section geometry, wall thickness, and connection details. Proper design and analysis are essential to ensure that C350L0 CHS structures can safely withstand anticipated loads and environmental conditions.

Design flexibility and versatility

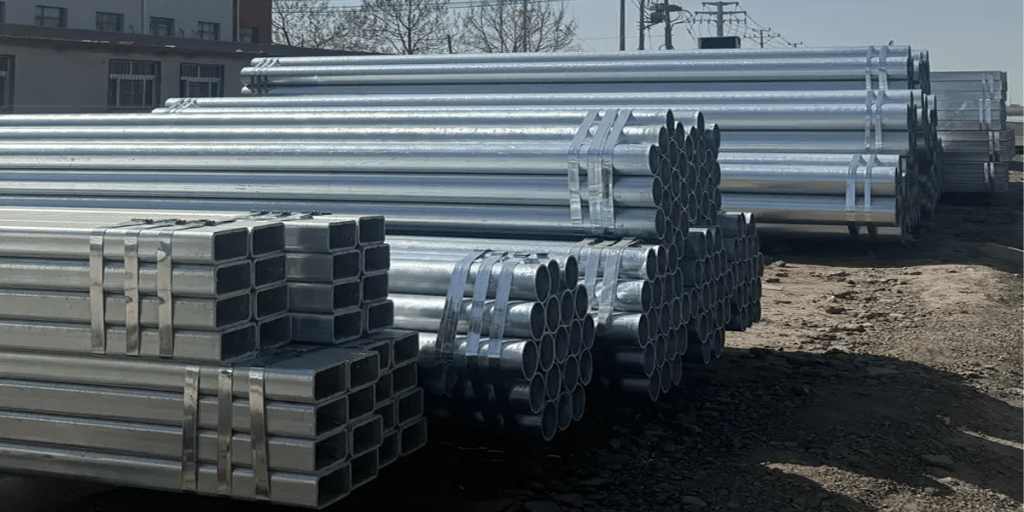

One of the key benefits of AS 1163 C350L0 CHS is its design flexibility and versatility. Cold-formed steel sections can be easily produced in a wide range of shapes and sizes, enabling innovative structural designs and complex geometries.

AS 1163 C350L0 circular hollow sections can be used in a variety of structural elements, including columns, beams, trusses and frames, enabling architects and engineers to create visually appealing and structurally efficient solutions. Case studies showcase the creative use of C350L0 CHS in architectural and engineering applications such as long-span bridges, high-rise buildings, and iconic structures.

Weldability and fabrication considerations

AS 1163 C350L0 CHS exhibits excellent weldability, making it suitable for a variety of fabrication processes. The material’s chemical composition and controlled manufacturing process ensure consistent weld quality and strength.

Fabrication considerations for AS 1163 C350L0 circular hollow sections include forming, cutting, and machining. The material’s ductility and formability allow efficient production of complex shapes and sections, while its strength ensures dimensional accuracy and stability during fabrication.

Corrosion resistance and durability

Corrosion resistance is a critical factor in determining the long-term performance and durability of structural materials. AS 1163 C350L0 CHS exhibits good corrosion resistance properties, particularly in indoor and mild outdoor environments.

In more corrosive environments, protective coatings or special surface treatments may be required to enhance the durability and longevity of C350L0 CHS structures. Periodic maintenance and inspection are also recommended to ensure the continued structural integrity of C350L0 CHS components.

Standards and code compliance

The use of AS 1163 C350L0 CHS in structural applications is governed by various industry standards and regulations. These standards ensure quality control, material traceability, and compliance with safety and performance requirements.

Manufacturers of C350L0 CHS must adhere to strict quality assurance measures and testing protocols to ensure compliance with the relevant standards. Designers and engineers must also comply with building codes and design guidelines specific to cold-formed steel structures when using C350L0 circular hollow sections.

Case studies and real-world applications

Numerous case studies and real-world applications demonstrate the successful use of AS 1163 C350L0 circular hollow sections in structural projects. These examples showcase the performance and benefits of C350L0 CHS in a variety of applications including industrial buildings, transportation infrastructure and emergency response structures.

The lessons learned from these case studies provide valuable insight into best practices for getting the most out of C350L0 CHS, including design considerations, connection details and construction techniques. These experiences contribute to the continuous improvement and advancement of cold-formed steel construction practices.

LONGMA produce and export AS 1163 C350L0 CHS/ circular hollow sections, AS/NZS 1163 C350L0 steel pipes , size from NPS2 to NPS 56, Sch10-XXS. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality AS NZS 1163 grade C250, AS NZS 1163 grade C350l0 with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.

References:

- AS/NZS 1163:2016 Cold-formed structural steel hollow sections

- Keerthan, P., & Mahendran, M. (2011). New design rules for the shear deformation of LiteSteel beams. Journal of Constructional Steel Research, 67(6), 886-896.

- Pham, C. H., & Hancock, G. J. (2012). Shear buckling of thin-walled channel sections. Journal of Constructional Steel Research, 71, 72-80.

- Schafer, B. W., & Peköz, T. (1998). Computational modeling of cold-formed steel: characterizing geometric imperfections and residual stresses. Journal of Constructional Steel Research, 47(3), 193-210.

- Keerthan, P., & Mahendran, M. (2013). Improved shear design rules for lipped channel beam structures. Journal of Constructional Steel Research, 90, 189-203.

- Tolerance -AS/NZS 1163:2016 CHS, RHS, SHS