- 1. What is ASTM A252 Steel Pipe?

- 2. Typical Applications of ASTM A252 Steel Pipe in Piling Foundations

- 3. Core Advantages of ASTM A252 Steel Pipe Piles

- 4. Comparison of ASTM A252 Steel Pipe Piles with Other Piling Materials

- 5. Construction and Testing Key Points for ASTM A252 Steel Piles in Foundation Piling Projects

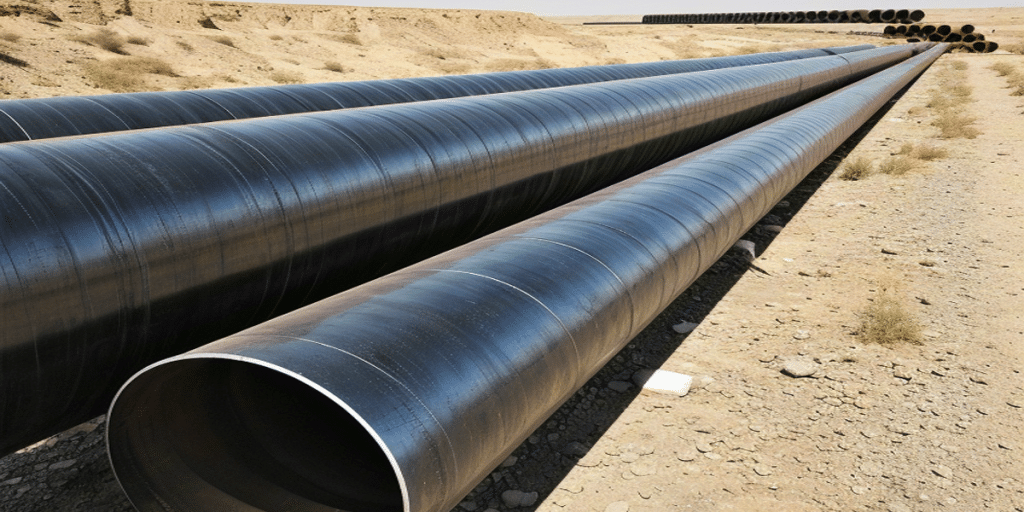

In modern bridge construction, ASTM A252 steel pipes have become an ideal choice for pile foundations and support structures due to their high strength, durability, and adaptability. With the rapid expansion of cross-river bridges, highways, and urban rail transit projects, the demand for high-quality piling pipes continues to grow. At the same time, green building concepts are driving the industry to focus more on corrosion resistance and sustainability. This article explores the advantages, market trends, and future prospects of ASTM A252 steel pipes in bridge construction!

What is ASTM A252 Steel Pipe?

ASTM A252 steel pipe is a structural steel pipe specifically designed for piling applications, widely used in bridge foundations, docks, building foundations, and other infrastructure projects. It is primarily used for bearing and support purposes, ensuring stability by being embedded deep underground or underwater.

Key Features of ASTM A252 Steel Pipe

1. High Strength and Durability – Suitable for heavy loads and complex geological conditions.

2. Excellent Weldability – Facilitates easy on-site construction and connections.

3. Multiple Grades Available – Includes Grade 1, Grade 2, and Grade 3, with Grade 3 being the strongest and most widely used.

4. Optional Corrosion Protection – Coatings, galvanization, or cathodic protection can enhance corrosion resistance, making it suitable for marine and wetland environments.

Applications of ASTM A252 Steel Pipe

Bridge Pile Foundations – Supports bridge structures and enhances stability.

Dock and Port Construction – Provides durable support for underwater structures.

Shoreline Protection – Prevents soil erosion and stabilizes riverbanks.

Deep Building Foundations – Ideal for high-rise buildings and challenging soil conditions.

Typical Applications of ASTM A252 Steel Pipe in Piling Foundations

As a crucial material for piling foundations, ASTM A252 steel pipes are widely used in bridges, ports, high-rise buildings, and other infrastructure projects. Below are some typical application scenarios:

1. Bridge Pile Foundations: In river and sea-crossing bridge construction, ASTM A252 steel pipe piles support bridge piers by transferring loads to stable soil layers, enhancing the bridge’s stability and seismic resistance.

2. Ports and Dock Construction: For ports and docks, steel pipe piles are used to build loading platforms and breakwaters, ensuring the structures withstand tidal forces, storm surges, and vessel impacts.

3. Deep Foundations for High-Rise Buildings: In areas with weak soil conditions, high-rise buildings rely on ASTM A252 steel pipe piles for deep foundations, preventing settlement and ensuring long-term stability.

4. Shoreline and Flood Protection: ASTM A252 steel pipes serve as retaining walls and protective piles in riverbank reinforcement and coastal defense projects, preventing soil erosion and enhancing structural integrity.

5. Oil and Gas Pipeline Support Piles: In energy infrastructure, ASTM A252 steel pipe piles provide structural support for oil and gas pipelines, ensuring stability in challenging terrains and seismic zones.

Core Advantages of ASTM A252 Steel Pipe Piles

ASTM A252 steel pipe piles have become an essential material for piling foundations in infrastructure projects such as bridges, docks, and buildings due to their high strength, durability, and versatility. Here are the core advantages:

1. High Strength and Load-Bearing Capacity: ASTM A252 steel pipes offer excellent compressive and bending strength, making them ideal for deep foundation piles, load-bearing supports, and retaining walls in heavy-duty applications.

2. Superior Corrosion Resistance: Designed for harsh environments such as wetlands or marine conditions, these steel pipes can be coated with corrosion-resistant layers, galvanized, or cathodically protected, significantly extending their lifespan and reducing maintenance costs.

3. Excellent Construction Adaptability: ASTM A252 steel pipe piles are adaptable to various installation methods, including driving, vibration, and drilled-in placement, making them suitable for different geological conditions and enhancing construction efficiency.

4. Outstanding Weldability: The material of ASTM A252 steel pipe piles is easy to weld, ensuring stable connections and the ability to extend or join piles for complex structural needs.

5. Cost-Effectiveness and Sustainability: Compared to traditional concrete piles, steel pipe piles are lighter, easier to transport, and install, while also being recyclable, aligning with green building practices.

Comparison of ASTM A252 Steel Pipe Piles with Other Piling Materials

1. ASTM A252 Steel Pipe Piles vs Concrete Piles

Load-Bearing Capacity:

ASTM A252 steel pipe piles are renowned for their superior load-bearing capacity, particularly in soft soil or deep foundation applications. They shine when subjected to axial and lateral loads.

Concrete piles, on the other hand, do an admirable job in lighter load applications, but their bending and tensile strengths are generally lower than steel pipe piles. They are also less forgiving when the soil conditions get tricky.

Corrosion Resistance:

One of the key advantages of ASTM A252 steel pipe piles is their exceptional corrosion resistance. They can be treated with coatings, galvanizing, or cathodic protection to withstand harsh marine or wetland environments, dramatically extending their lifespan.

Concrete piles, while durable in water, often suffer from corroding steel reinforcement, especially when exposed to water and aggressive chemicals, resulting in costly repairs.

Construction Flexibility:

Steel pipe piles offer a range of installation methods—they can be driven, vibrated, or drilled into the ground with relatively swift and efficient machinery.

Concrete piles, in contrast, often require a lengthier curing process, leading to longer construction timelines and a greater reliance on specialized equipment. The waiting game can feel like watching paint dry.

2. ASTM A252 Steel Pipe Piles vs H-Beam Piles

Strength and Load-Bearing Ability:

H-beam piles offer outstanding bending resistance and shear strength, especially when heavy loads or seismic forces are at play. They are perfect for high-stress environments like those found in high-rise buildings or large infrastructure projects.

However, ASTM A252 steel pipe piles are equally strong in terms of their axial capacity and provide better lateral load resistance in soft soils or areas requiring deeper foundations.

Corrosion Resistance:

While H-beam piles can be coated for protection, they are still vulnerable to corrosion, particularly when exposed to moisture or salts over long periods.

ASTM A252 steel pipe piles, thanks to their ability to be coated, galvanized, or protected cathodically, offer superior corrosion resistance, making them a better choice for long-term performance in harsh environments.

Construction Efficiency:

H-beam piles typically require more heavy-duty equipment for driving and installation. Their size and weight can make installation cumbersome, especially in tight spaces.

ASTM A252 steel pipe piles, by comparison, are easier to handle and install in a variety of geotechnical conditions, making them more adaptable and efficient, particularly in urban environments where space is tight and time is of the essence.

ASTM A252 Steel Pipe Piles vs Ordinary Structural Steel Pipes

Strength and Stability:

Ordinary structural steel pipes are generally used for lighter applications and are not designed for deep foundation support. Their strength is lower compared to ASTM A252 steel pipe piles, which are specifically engineered for heavy-duty foundation applications.

ASTM A252 steel pipe piles are designed with reinforcement in mind, making them far superior for bearing the forces associated with deep foundations, bridges, and other large-scale projects.

Corrosion Resistance:

Ordinary structural steel pipes are often more susceptible to rust and corrosion if left uncoated, especially in moist environments.

ASTM A252 steel pipe piles are designed to be corrosion-resistant with proper coating or galvanization, making them highly durable in moist or aggressive environments.

Construction and Adaptability:

Ordinary structural steel pipes are more commonly used in general support structures but lack the necessary stability and load-bearing capacity for piling.

ASTM A252 steel pipe piles offer a higher degree of adaptability and can be used in various foundation types due to their strength and construction flexibility.

Construction and Testing Key Points for ASTM A252 Steel Piles in Foundation Piling Projects

In foundation piling projects, the correct selection of steel pipes, construction techniques, and quality testing are crucial to ensuring the success of the project when using ASTM A252 steel pipes. Below are the key points for construction and testing in foundation piling projects:

1. Steel Pipe Selection Key Points

Material Requirements: ASTM A252 steel pipe piles are divided into three grades:

Grade 1: Suitable for light load applications, with a minimum yield strength of 240 MPa.

Grade 2: Suitable for moderate load applications, with a minimum yield strength of 300 MPa.

Grade 3: Suitable for heavy load applications, with a minimum yield strength of 350 MPa. The grade of the steel pipe should be chosen based on the load requirements of the project.

Steel Pipe Specifications: Based on design requirements, choose the appropriate diameter and wall thickness. ASTM A252 steel pipes typically range from 2 inches to 72 inches (50mm to 1800mm) in diameter.

Surface Treatment: Since foundation piles are often exposed to wet or corrosive soils, it’s recommended to choose steel pipes with corrosion-resistant coatings or hot-dip galvanization to enhance their durability and extend service life.

2. Construction Techniques Key Points

Construction Methods:

Impact Hammer Method: Suitable for soft soil or shallow silt layers, the steel pipe pile is driven into the ground using a heavy hammer.

Vibration Piling Method: Ideal for harder soil layers or situations requiring faster construction, the steel pipe pile is installed using vibration equipment.

Drilled Piling Method: When the soil is hard or complicated, the steel pipe pile is inserted into a pre-drilled hole.

Static Load Method: Uses pressure equipment to push the pile into the ground, suitable for urban areas where minimal vibration is desired.

Pile Positioning and Jointing:

Accurate pile positioning and proper jointing are critical during construction. Ensure that each pile is properly aligned to avoid deviations.

Pile Connections: Use butt welding or threaded connections to ensure the strength and stability of the joints.

Construction Control:

Vibration Control: Avoid excessive vibration that could disturb surrounding soil or undermine the pile foundation’s stability.

Verticality of Piles: Use equipment to monitor the verticality of the pile during installation to ensure it remains upright, avoiding construction deviations.

3. Quality and Standards Testing Verification

Steel Pipe Quality Inspection:

Surface Inspection: Check the steel pipe for cracks, dents, or other defects to ensure the pipe meets the required quality standards.

Dimensional Testing: Measure the outer diameter, wall thickness, and length of the steel pipe to ensure they meet design specifications.

Tensile and Compressive Strength Testing: Perform material tests to check the pipe’s tensile strength and compressive strength, ensuring they meet the ASTM A252 standards.

Construction Quality Control:

Pile Depth and Pile Top Elevation Measurement: Regularly check the pile depth and pile top elevation to ensure they meet design specifications.

Static Load Testing: For key pile locations, perform static load tests to assess the bearing capacity of the pile foundation.

Pile Integrity Testing: After construction, use methods such as ultrasonic testing to check for cracks, voids, or other defects in the pile.

Compliance Testing:

Standard Acceptance: Periodically verify that the steel pipe piles conform to the ASTM A252 standard throughout the construction process.

Corrosion Coating Inspection: For coated or galvanized steel pipe piles, inspect the uniformity and adhesion of the protective coating to ensure long-term corrosion resistance.

In foundation piling projects, ASTM A252 steel pipe piles offer excellent strength, durability, and adaptability to various soil conditions. By selecting the right materials, using proper construction methods, and performing thorough quality control and testing, engineers can ensure a stable and reliable foundation. As infrastructure projects grow in complexity, high-performance piling solutions like ASTM A252 steel pipes become increasingly vital, ensuring secure and long-lasting foundations.

Feel free to leave us a message with any topics you’d like to learn more about. We also warmly welcome buyers to visit our factory!