How can pipeline systems ensure long-term stability in oil and gas transportation? Which type of pipe can withstand harsh environments and high-pressure conditions while offering corrosion resistance, mechanical strength, and safety? As global energy infrastructure continues to advance, why has ASTM A672 steel pipe become the industry’s top choice? As a professional steel pipe manufacturer, Hebei Longma Steel Pipe Manufacturing Co., Ltd. (LONGMA) has over 20 years of experience, providing high-quality, corrosion-resistant pipes to support the safety and efficiency of various projects worldwide. In this article, we will explore the performance advantages, applications, and industry significance of ASTM A672 steel pipes, helping you find the answers to these questions!

Overview of ASTM A672 Steel Pipe

ASTM A672 steel pipe is a carbon steel pipe specifically designed for high-pressure oil and gas transportation systems, meeting the stringent standards set by the American Society for Testing and Materials (ASTM). It is widely used in oil, gas, and other fluid transportation systems and plays a key role in the development of energy infrastructure.

Characteristics of ASTM A672 Steel Pipe

Strong Corrosion Resistance: ASTM A672 steel pipes are made from high-quality carbon steel and are carefully engineered during manufacturing to ensure excellent corrosion resistance. This makes them ideal for use in harsh environments, whether in offshore oil pipelines or underground transportation systems, significantly extending the lifespan of the pipeline.

Excellent Mechanical Properties: ASTM A672 steel pipe exhibits high tensile and yield strength, making it suitable for high-pressure and ultra-high-pressure conditions, ensuring the safe and reliable transport of oil and gas.

Wide Adaptability: This steel pipe is versatile and can be used with various types of connections, such as welding or threading, and can be customized to meet specific requirements, making it ideal for a wide range of environmental conditions.

Compliance with International Standards: ASTM A672 steel pipe conforms to international standards like API 5L, ensuring its applicability globally. Its manufacturing process follows stringent quality control systems to guarantee high quality and stability.

Comparison with Other Pipe Standards

ASTM A672 steel pipe conforms to international standards like API 5L, ensuring its applicability globally. Its manufacturing process follows stringent quality control systems to guarantee high quality and stability.

ASTM A53 Steel Pipe vs. ASTM A672 Steel Pipe: ASTM A53 steel pipe is typically used in low to medium pressure transport systems, while ASTM A672 steel pipe is designed for high-pressure environments. As a result, ASTM A672 steel pipe offers superior pressure resistance and mechanical strength compared to ASTM A53 steel pipe.

ASTM A106 Steel Pipe vs. ASTM A672 Steel Pipe: ASTM A106 steel pipe is generally used in high-temperature and high-pressure applications, particularly in oil and gas transportation, and is suitable for welded pipelines. In contrast, ASTM A672 steel pipe not only performs well under high temperature and pressure but also provides enhanced corrosion resistance, making it more suitable for use in complex environments.

API 5L Steel Pipe vs. ASTM A672 Steel Pipe: API 5L steel pipe is primarily designed for oil and gas pipelines, whereas ASTM A672 steel pipe is more focused on high-pressure applications. Both can be used for oil and gas transport, but ASTM A672 steel pipe is better suited for certain conditions due to its superior corrosion resistance and capacity to withstand high-pressure, long-distance transport.

Applications of ASTM A672 Steel Pipe in the Oil and Gas Industry

Below are the key applications of ASTM A672 steel pipe in the oil and gas industry:

1. Oil and Gas Transmission Pipelines: In long-distance oil and gas transportation, the stability and durability of pipelines are critical. ASTM A672 steel pipe, with its high strength and corrosion resistance, has become an indispensable material in oil and gas transmission systems. It is widely used in both oil pipelines and natural gas pipelines, where its high-pressure tolerance ensures stable operation in complex underground and offshore environments.

2. Offshore Oil and Gas Platform Pipelines: Offshore oil and gas platforms face extreme weather and corrosive environments, demanding pipes with outstanding corrosion resistance and strength. ASTM A672 steel pipe, with its resistance to seawater corrosion and high-pressure capability, is an ideal pipeline material for offshore oil and gas platforms. It can withstand corrosion and high-pressure conditions in marine environments, ensuring the safety of oil and gas transport.

3. Liquefied Natural Gas (LNG) Transport Pipelines: Liquefied natural gas (LNG) requires transportation at ultra-low temperatures and high pressures, so the pipelines must be exceptionally strong and pressure-resistant. ASTM A672 steel pipe meets these demands, offering a reliable solution. Its excellent mechanical properties make it an ideal choice for LNG transport systems.

4. Oil and Gas Storage and Distribution Systems: Oil and gas storage facilities and distribution pipelines must withstand varying pressure levels. ASTM A672 steel pipe offers excellent pressure resistance and reliability, making it suitable for storage and distribution systems. The corrosion resistance of the pipes is particularly important in storage tanks and transportation lines, which must remain free from corrosion or leakage over long periods of use.

5. Other High-Pressure Transportation Systems: In addition to oil and gas transport, ASTM A672 steel pipe is also used in other high-pressure transport systems, such as chemical, metallurgical, and water treatment applications. Its superior mechanical properties and ability to adapt to a variety of environments make it an ideal choice for various high-pressure transport systems.

High-Temperature and Corrosion Resistance of ASTM A672 Steel Pipe

ASTM A672 steel pipe, known for its high strength, exhibits excellent high-temperature and corrosion resistance properties, making it a popular choice for high-pressure transportation systems in industries like oil, gas, and chemicals. Its superior performance makes it ideal for pipeline systems operating in harsh environments, particularly those exposed to high temperatures and corrosive conditions. Below is a detailed overview of the high-temperature and corrosion resistance properties of ASTM A672 steel pipe:

1. High-Temperature Resistance

ASTM A672 steel pipe offers outstanding high-temperature resistance, maintaining stable mechanical properties even under high heat conditions. Its high strength and good ductility allow it to withstand the stresses and deformations encountered in high-temperature oil and gas transportation processes, ensuring that it doesn’t crack or deform. This high-temperature performance makes it widely used in steam and liquid transport systems that must endure extreme thermal loads.

Thermal Stability: ASTM A672 steel pipe can operate at higher temperatures, typically up to 500°C, while maintaining its strength and hardness, making it suitable for most high-temperature transportation requirements.

Thermal Expansion Control: The steel pipe exhibits good thermal expansion control, effectively reducing the impact of thermal stress on the pipeline during temperature fluctuations.

2. Corrosion Resistance

Manufactured using high-quality carbon steel and undergoing strict processing, ASTM A672 steel pipe possesses exceptional corrosion resistance. This property enables it to perform reliably in harsh environments, particularly in oil, gas, and offshore platform pipelines, which are often exposed to seawater, acidic gases, and other corrosive agents.

Seawater Corrosion Resistance: The steel pipe is widely used in offshore oil and gas platforms and marine pipelines due to its ability to resist seawater corrosion, thus extending the service life of the pipelines.

Acidic Environment Corrosion Resistance: For oil and gas media containing sulfur compounds and carbon dioxide, ASTM A672 steel pipe demonstrates excellent resistance to acidic corrosion, ensuring protection from the corrosive effects of acidic gases.

Hydrogen Embrittlement Resistance: After treatment, the steel pipe is resistant to hydrogen embrittlement, which helps prevent this issue in oil and gas transport, ensuring pipeline system safety.

3. Enhanced Corrosion Resistance Through Design

Coating Protection: For additional corrosion protection, ASTM A672 steel pipe can be coated with special layers such as anti-corrosion coatings, epoxy coatings, or polyethylene coatings, enhancing its ability to resist corrosion, particularly in underground pipelines and offshore platforms.

Wear Resistance: The steel pipe also boasts excellent wear resistance, allowing it to function reliably even in transporting media that contain sand, gravel, or other abrasive materials.

4. Real-World Case Studies Demonstrating the Performance of ASTM A672 Steel Pipe

1. Offshore Oil & Gas Platforms (North Sea)

In the North Sea, where oil and gas operations face extreme temperatures and corrosive seawater environments, ASTM A672 steel pipe has been used in the construction of pipelines that transport oil and gas from offshore platforms to onshore processing facilities.

Challenges: The pipeline had to withstand both high pressure and the corrosive effects of seawater, while operating in harsh weather conditions.

Solution: ASTM A672 steel pipe was selected due to its exceptional corrosion resistance to seawater and its ability to handle the extreme pressures found in offshore drilling. Its resistance to hydrogen embrittlement and high-strength properties ensured the pipeline’s structural integrity over long periods of use.

Outcome: The ASTM A672 steel pipe demonstrated excellent performance, with no significant signs of corrosion or mechanical failure over several years, significantly reducing maintenance costs.

2. LNG Transport Pipeline (Australia)

In the construction of a liquefied natural gas (LNG) transport pipeline in Australia, ASTM A672 steel pipe was chosen for its ability to withstand extremely low temperatures while maintaining high strength and structural integrity.

Challenges: The pipeline had to transport LNG at temperatures as low as -160°C, requiring materials that would not crack or lose their mechanical strength under such conditions.

Solution: ASTM A672 steel pipe was selected due to its excellent high-temperature resistance and ability to maintain toughness in low-temperature environments. Its superior mechanical properties made it an ideal material for the demanding conditions of LNG transportation.

Outcome: The pipeline has operated efficiently since installation, with ASTM A672 steel pipe showing no signs of weakening or failure despite the extreme temperatures, ensuring a reliable and continuous flow of LNG.

Key Considerations for the Selection and Installation of ASTM A672 Steel Pipe

1. Key Considerations for Selecting ASTM A672 Steel Pipe

a. Identify the Operating Environment

When selecting ASTM A672 steel pipe, the first step is to understand the operating environment of the pipeline. This includes factors such as temperature, pressure, and the properties of the transported media (such as acidity or corrosiveness). For high-temperature and high-pressure applications, the heat and corrosion resistance of ASTM A672 are essential.

Temperature and Pressure: Ensure the steel pipe meets the temperature and pressure requirements of the application. ASTM A672 is known for its excellent high-temperature resistance and is suitable for pipelines operating under extreme conditions.

Corrosive Media: If the pipeline will be exposed to corrosive media, such as seawater or acidic gases, select ASTM A672 steel pipe with protective coatings to enhance its corrosion resistance.

b. Pipe Dimensions and Specifications

When selecting ASTM A672 steel pipe, ensure the pipe dimensions, wall thickness, and required pressure strength align with the specific application. The specifications of ASTM A672 pipes should be chosen based on the fluid transportation volume, pipeline length, and external pressure factors.

Pipe Diameter: Choose an appropriate pipe diameter based on the flow rate and speed of the fluid being transported.

Wall Thickness: Select the right wall thickness based on the pressure the pipeline will endure. Typically, the thicker the wall, the higher the pressure the pipeline can handle.

c. Consider Environmental Protection and Maintenance Requirements

To extend the life of the pipeline, it is important to consider environmental protection and future maintenance when selecting ASTM A672 steel pipe. Special environments (such as humid areas or underground pipelines) may require additional protective coatings or measures.

2. Key Considerations for Installing ASTM A672 Steel Pipe

a. Pre-installation Inspection: Before installation, the ASTM A672 steel pipe should be inspected for compliance with specifications and quality standards. Common checks include examining the pipe for any surface damage, cracks, corrosion, or other defects during transportation and storage.

b. Connection Methods

ASTM A672 steel pipe can be connected using welding, threading, or flange methods. The choice of connection method should depend on factors such as pipeline working pressure, fluid medium, and environmental considerations.

Welding: Suitable for high-pressure, high-temperature environments, providing a strong and reliable seal.

Threaded Connections: Ideal for low-pressure pipelines, providing quick installation and easy maintenance.

Flanged Connections: Used for pipelines that need to be disassembled and serviced regularly.

c. Pipe Support and Fixing: During installation, ensure that the pipes are properly supported and fixed. The pipes should be installed on brackets or support structures that comply with industry standards to prevent pipe displacement or deformation due to thermal expansion or pressure changes over time. This is especially important in high-temperature applications, where pipe expansion must be effectively managed.

d. Corrosion Protection

For ASTM A672 steel pipe used in harsh environments, additional anti-corrosion measures should be taken during installation. Common methods include:

Coating Protection: Use epoxy resin, polyethylene, or other coatings to protect the pipe surface from corrosive media.

Cathodic Protection: This is particularly useful for underground or underwater installations to prevent electrochemical corrosion.

e. Leak Testing

After installation, conduct air or water leak tests to ensure the integrity of the pipeline. Testing should be done at the prescribed pressure levels to ensure the pipeline will operate safely without leaks.

3. Post-Installation Maintenance and Monitoring

a. Regular Inspections: After installation, regular inspection of the ASTM A672 steel pipe is critical. The focus should be on the protective coatings, weld joints, and connection points for any signs of corrosion, leaks, or damage.

b. Maintenance of Corrosion Protection: For coated pipes, regularly check the coating for any signs of peeling, cracking, or wear. Prompt repairs should be made to maintain the corrosion resistance and ensure the pipeline’s longevity.

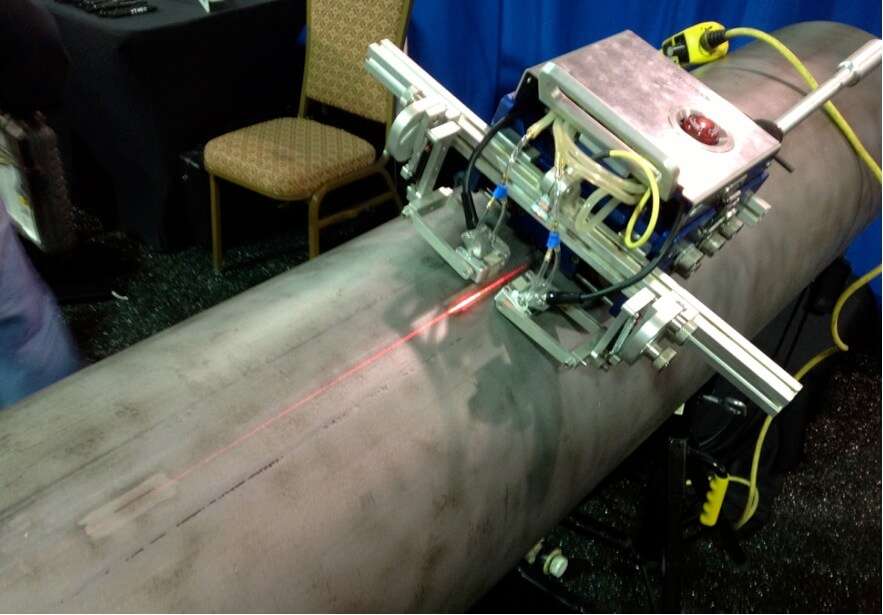

4. Quality Control and Testing in the Production Process of ASTM A672 Steel Pipe

The production of ASTM A672 steel pipes involves a series of critical steps to ensure that the pipes meet the required standards of performance, durability, and safety. Quality control and testing are integral parts of this process, ensuring that the steel pipes maintain their mechanical properties, resistance to corrosion, and reliability under extreme conditions.

Future Trends and Developments

1. Enhanced Performance and Increased Corrosion Resistance

As oil and gas transmission pipelines are exposed to more extreme environments (such as marine settings, high-temperature, and high-pressure underground environments), the demand for higher corrosion resistance is intensifying. In the future, ASTM A672 steel pipes will likely continue to enhance their surface treatment technologies and alloy modifications to improve corrosion resistance, especially in chemical and marine corrosive environments.

This will include:

Innovative Coating Technologies: The development of more efficient and durable protective coatings, such as high-performance epoxy coatings or advanced nanocoatings, to extend the lifespan of pipes.

Optimized Alloy Composition: Adding more corrosion-resistant elements like molybdenum and chromium to the steel composition to enhance its resistance to corrosion.

2. Smart Manufacturing and Automation

The production process for ASTM A672 steel pipes will become increasingly intelligent and automated. With the advancement of Industry 4.0, technologies like smart manufacturing, artificial intelligence (AI), and big data will play a crucial role in enhancing the efficiency and quality of steel pipe production.

Key developments will include:

Intelligent Inspection and Predictive Maintenance: Using big data analytics and machine learning to predict the service life and potential failures of pipelines, enabling proactive maintenance or replacement to ensure safe operation.

Automated Production Lines: Employing robotics, 3D printing, and automated inspection systems to increase production efficiency, reduce human error, and ensure consistency and reliability in product quality.

3. Environmental Protection and Sustainability

With increasing global emphasis on environmental protection and sustainable development, the steel pipe industry faces the challenge of reducing carbon emissions, conserving resources, and enhancing material recyclability. In the future, the production of ASTM A672 steel pipes will focus more on environmentally friendly technologies, including:

Green Manufacturing Processes: Implementing energy-efficient and environmentally friendly production methods, such as waste gas recovery and green smelting technologies, to reduce emissions and pollution during manufacturing.

Circular Economy: Promoting the recycling and reuse of discarded pipelines, reducing resource consumption, and driving the sustainable development of steel pipe products.

4. Demand for High-Strength and Large-Diameter Pipes

As the volume of oil and gas transportation increases, particularly for cross-border oil and gas pipelines, the demand for high-strength, large-diameter steel pipes continues to grow. ASTM A672 steel pipes will focus on improving the pipe’s load-bearing capacity and adaptability to large-scale transportation systems, including:

Development of High-Strength Materials: Researching and developing higher strength and pressure-resistant steel pipes to meet the requirements of deep-sea oil and gas extraction and high-pressure transmission.

Large-Diameter Pipe Design and Production: With the increasing need for higher transportation capacities, the demand for large-diameter steel pipes will surge, and pipe manufacturers will continue optimizing the production processes for larger pipe sizes.

As the oil and gas industry grows, ASTM A672 steel pipes remain essential for ensuring durability, safety, and efficiency in energy infrastructure projects. At Hebei Longma Steel Pipe Manufacturing Co., Ltd., with over 20 years of experience, we provide high-quality, reliable steel pipes to meet your needs! We welcome professionals and partners to visit our company, explore our facilities, and discuss how we can support your projects. Let’s work together for a successful future!