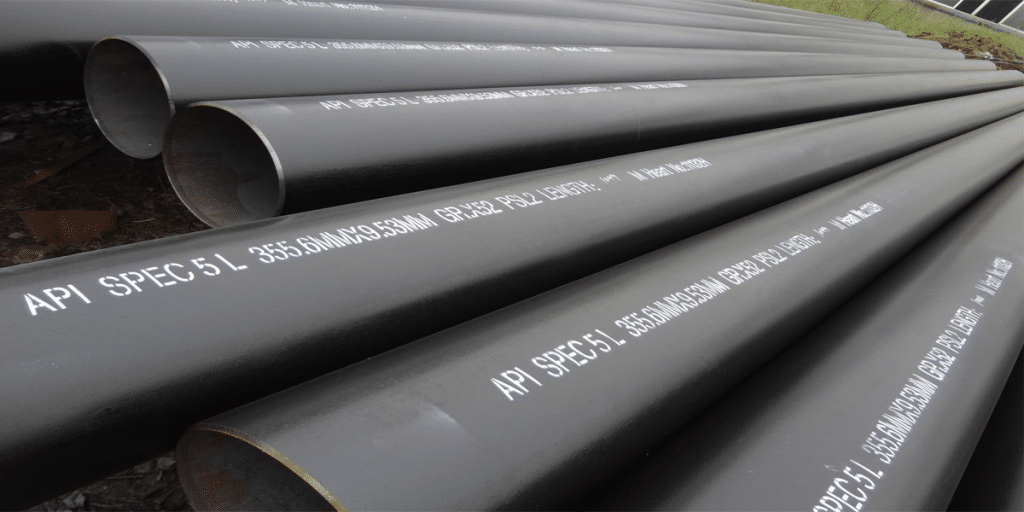

What is API 5L PSL1?

API 5L PSL1 is a specification developed by the American Petroleum Institute (API) for steel pipes used in the transportation of oil, gas, and other fluids in the petroleum and natural gas industries. PSL1 stands for Product Specification Level 1, which sets the basic requirements for chemical composition, mechanical properties, and testing for seamless and welded steel pipes. These requirements ensure the pipes’ quality and performance in various applications, but they are less stringent compared to PSL2, which has additional requirements for toughness and non-destructive testing.

Key Features of API 5L PSL1 LSAW pipe:

– Chemical Composition: Specifies limits for elements such as carbon, manganese, phosphorus, and sulfur.

– Mechanical Properties: Defines the minimum yield and tensile strength.

– Manufacturing Methods: Applicable to both seamless and welded pipes.

– Testing Requirements: Includes hydrostatic testing and dimensional checks, but less stringent than PSL2.

Applications of API 5L PSL1 Pipes:

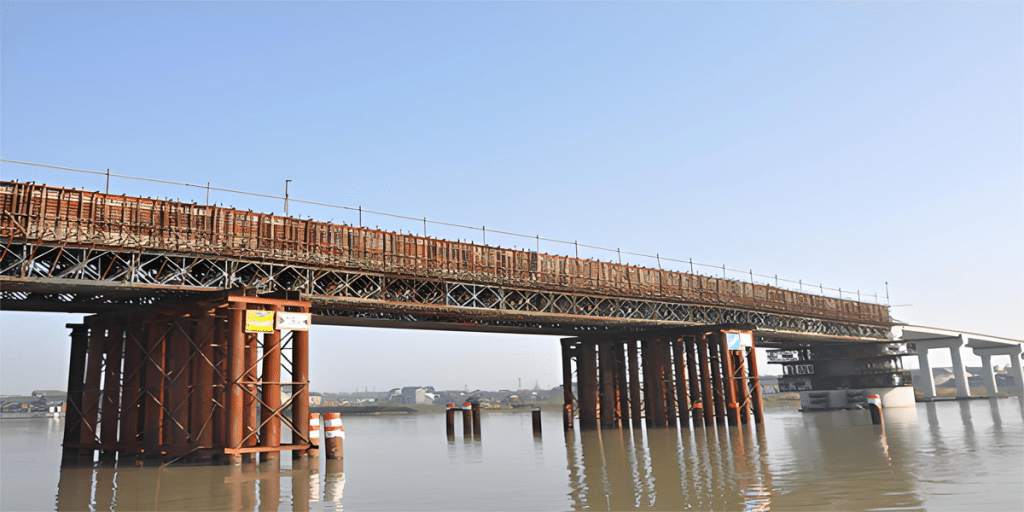

– Oil and Gas Transportation: Used for pipelines transporting crude oil, natural gas, and other petroleum products.

– Water Transmission: Suitable for conveying water in various settings.

– Structural Applications: Used in construction and engineering for structural support.

Advantages of API 5L PSL1 Pipes:

-Cost-Effective: Generally less expensive than PSL2 pipes due to fewer testing and stricter requirements.

-Versatility: Suitable for a wide range of applications, including oil, gas, and water transportation, as well as structural uses.

-Availability: Widely available in various grades and sizes, making it easier to source for different projects.

-Basic Compliance: Meets essential industry standards for chemical composition, mechanical properties, and basic testing, ensuring reliability.

-Simplified Testing: Requires less stringent testing compared to PSL2, which can expedite the manufacturing and certification process.

For detailed specifications, you can refer to the [API 5L PSL1 standard document](https://www.api.org).

Grades of API 5L PSL1:

-Grade A25

-Grade A, B (most common)

-Grades X42, X46, X52, X56, X60, X65, X70, X80

-Outer Diameter: 1/2” to 2”, 3”, 4”, 6”, 8”, 10”, 12”, 16 inches, 18 inches, 20 inches, 24 inches up to 72 inches.

-Thickness: SCH 10. SCH 20, SCH 40, SCH STD, SCH 80, SCH XS, to SCH 160

-Manufacturing Types: ERW (Electric resistance welded), SAW (Submerged Arc Welded) in LSAW, DSAW

-Length Range: SRL (Single Random Length), DRL (Double Random Length), 20 FT (6 meters), 40FT (12 meters) or, customized Protection Caps in plastic or iron

-Surface Treatment: Natural, Varnished, Black painting, FBE, 3PE (3LPE), 3PP, FBE

Each grade differs in its chemical composition and mechanical properties, particularly in terms of yield strength and tensile strength. These differences allow for various applications depending on the required strength and environmental conditions.

Delivery condition of API 5L PSL1 line pipes:

| PSL1 | Delivery Condition | Pipe Grade |

| As-rolled, normalized, normalizing formed | A | |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered or if agreed Q&T SMLS only | B | |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered | X42, X46, X52, X56, X60, X65, X70 |

Related topic:

API 5LPSL1 VS PSL2

What is PSL2?

What is NACE MR0175/ISO 15156 for Steel Pipe?

LONGMA produce and export API 5L PSL1 line pipes since 2003. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always produce & supply high quality API 5L PSL1 steel pipe, API 5L Gr B PSL1 LSAW pipes, API 5L X42 PSL1 ERW pipe, API 5L X52 PSL1 ERW pipe, API 5L X60 psl1 line pipe with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.