- 1. Material Composition of ASTM A671 EFW steel pipe:

- 2. Manufacturing Process of ASTM A671 EFW steel pipe:

- 3. Steel Grades in ASTM A671 EFW Steel Pipe:

- 4. Class Designation in ASTM A671 EFW Steel Pipe:

- 5. Mechanical Properties of ASTM A671 EFW Steel Pipe:

- 6. Applications of ASTM A671 EFW steel pipes

- 7. Testing Requirements of ASTM A671 EFW steel pipes

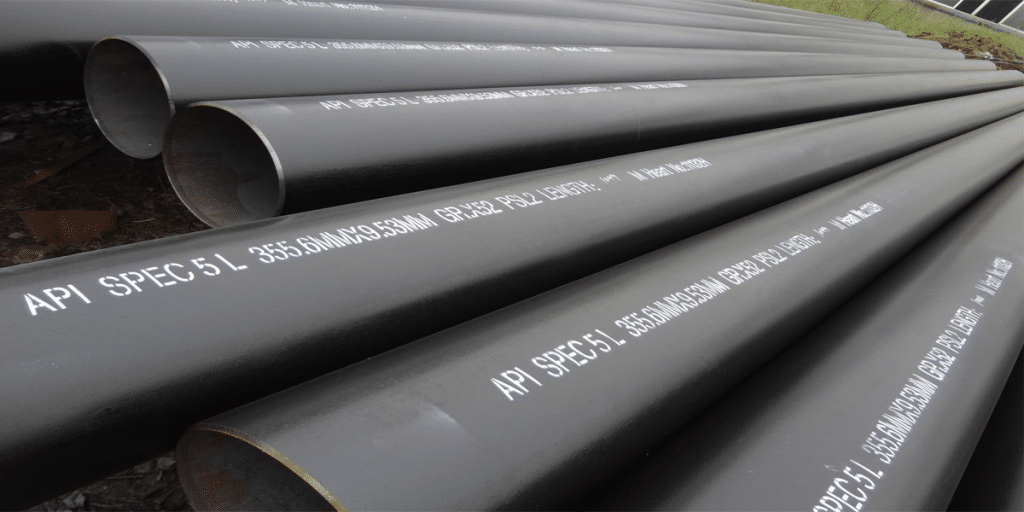

What is ASTM A671 EFW steel pipe?

ASTM A671 efw steel pipe (Grade CC60 CC65 CC70)is a specification created by ASTM International, focusing on electric-fusion-welded (EFW) steel pipes designed for atmospheric and lower temperatures. These pipes are typically used in industries such as power generation, petrochemicals, and oil and gas. The standard ensures that the pipes meet specific mechanical and chemical properties, making them suitable for their intended applications.

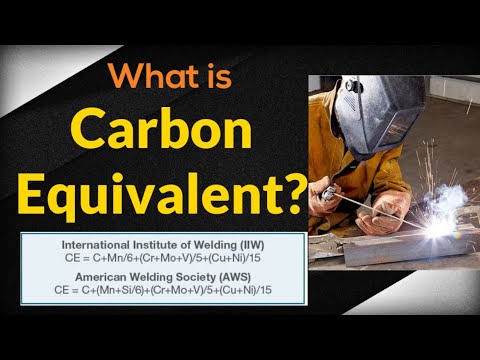

Material Composition of ASTM A671 EFW steel pipe:

– ASTM A671 covers pipes made from carbon steel plates.

– The pipes are formed by electric-fusion welding (EFW) of the steel plates.

– The material must meet the chemical composition requirements specified in the standard to ensure uniform quality.

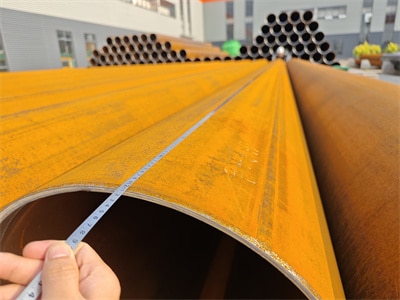

Manufacturing Process of ASTM A671 EFW steel pipe:

– Steel plates are formed into cylindrical shapes and welded using EFW.

– The welding process is carefully controlled, and the weld seam undergoes rigorous testing to ensure strength and quality.

– The finished pipes are typically used in low-temperature environments or under atmospheric conditions.

Steel Grades in ASTM A671 EFW Steel Pipe:

ASTM A671 includes various steel grades, each with specific alloying elements and mechanical properties. The steel grades typically align with other ASTM specifications, particularly those for steel plates.

– ASTM A671 Grade CC60: Equivalent to ASTM A516 Grade 60

– ASTM A671 Grade CC65: Equivalent to ASTM A516 Grade 65

– ASTM A671 Grade CC70: Equivalent to ASTM A516 Grade 70

Class Designation in ASTM A671 EFW Steel Pipe:

The class designation in ASTM A671 refers to the heat treatment and testing conditions of the pipes. The standard provides several classes, each indicating a different treatment or testing regimen.

– Class 10: No post-weld heat treatment is required.

– Class 11: Pipes are stress-relieved after welding.

– Class 12: Pipes are normalized after welding.

– Class 13: Pipes are quenched and tempered after welding.

– Class 22: Weld seam is radiographically inspected after welding.

Mechanical Properties of ASTM A671 EFW Steel Pipe:

The mechanical properties of ASTM A671 pipes are critical for their performance in service. These properties include:

– Tensile Strength: Varies according to grade and class, ensuring the pipe can withstand internal pressures.

– Yield Strength: The point at which the pipe material begins to deform permanently.

– Elongation: Indicates the ductility of the pipe material, showing how much it can stretch before breaking.

Applications of ASTM A671 EFW steel pipes

Pipes made according to ASTM A671 are commonly used in:

– Power Plants: For high-pressure steam lines and other critical applications.

– Petrochemical Industry: For transporting chemicals, gases, and other fluids.

– Oil and Gas Industry: In pipelines and distribution systems where durability and reliability are crucial.

Testing Requirements of ASTM A671 EFW steel pipes

ASTM A671 includes several testing requirements to ensure the pipes’ quality and integrity:

– Tension Tests: Assess tensile strength and yield strength.

– Hydrostatic Tests: Verify that the pipe can withstand internal pressures without leaking.

– Non-Destructive Testing (NDT): Techniques like ultrasonic or radiographic testing are used to inspect the weld seam for defects.

– S1: Tension and Bend Test

– S2: Charpy V-Notch Test

– S3: Hardness Test

Reference documents:

ASTM A671/A671M-16a

ASTM A516/A516M-17

ASTM A671 provides a comprehensive framework for the production of EFW steel pipes designed for atmospheric and low-temperature service. By specifying grades and classes with distinct mechanical and chemical properties, the standard ensures that the pipes meet the necessary performance criteria for their intended applications. This helps maintain safety, reliability, and efficiency in critical industrial processes.

LONGMA produce and export ASTM A671 CC60 CL22 S2, ASTM A671 GR CC65 CL12 EFW steel pipes since 2003. As one of China leading steel pipes manufacturers since 2003, certified by API 5L, ISO9001, ISO14001, FPC, LONGMA always supply high quality A671 CC60 CL22 EFW Steel pipes with full range pipe grades & pipe specifications. Contact by info@ilongma.com to get more information.