What is Carbon Equivalent Formula?

Carbon Equivalent (CE) is an important parameter in steel production as it indicates the weldability, hardenability and susceptibility of a steel to brittle fracture. Carbon Equivalent is particularly important in welding applications because the composition of a steel greatly affects its behavior during and after welding.

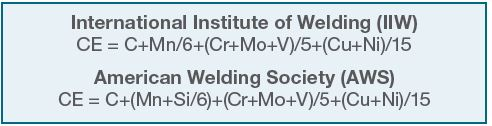

How to calculate carbon equivalent?

CE = C + Mn/6 + (Cr+Mo+V)/5 + (Ni+Cu)/15

*Calculate carbon equivalents online:

https://www.knauf-interfer.com/en/service/online-tools/cev-calculator

For example

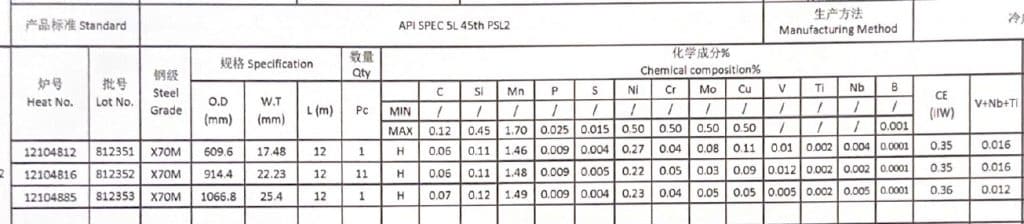

API 5L PSL2 X70M LSAW steel pipes with checmical composition as below, the Carbon Equivalent should be:

(CE)IIW=0.06+1.46/6+(0.04+0.08+0.01)/5+(0.11+0.27)/15=0.35(35%)

Here are a few reasons why carbon equivalency is important for steel:

1. **Weldability**: Carbon equivalents help predict the weldability of steel, which is critical in welding applications. High carbon equivalents can lead to problems such as hot cracking, cold cracking and hydrogen cracking during welding. By considering the carbon equivalent, welders and engineers can minimize the risk of weld defects by selecting the proper welding procedure, preheat temperature and filler material.

2. **Hardenability**: Carbon equivalent is related to the hardenability of a steel, which is defined as the depth and uniformity of hardness that can be achieved through heat treatment processes such as quenching and tempering. The higher the carbon equivalent, the higher the hardenability of the steel, i.e. the deeper the depth of hardening. This information is important for designing components with specific mechanical properties.

3. **Brittle fracture**: High carbon equivalent steels are more susceptible to brittle fracture, especially at low temperatures. Brittle fracture can occur suddenly and without warning, leading to structural failure. By controlling the carbon equivalent, engineers can reduce the risk of brittle fracture and ensure the safety and reliability of steel structures, especially in critical applications such as pressure vessels and piping.

4. **MATERIAL SELECTION**: Engineers use carbon equivalency as a material selection criterion when specifying steel grades for specific applications. Different applications require steels with specific properties, and carbon equivalency is one of the factors considered along with other material properties such as strength, toughness, corrosion resistance and weldability.

Carbon equivalency provides valuable information for evaluating and controlling the performance of steels, particularly in welding, heat treating and structural design applications. By understanding and managing carbon equivalent levels, manufacturers and engineers can produce steel components that meet performance requirements while ensuring safety and reliability.